Unround ceramsite and preparation system thereof

A preparation system, non-round pottery technology, applied in raw material extrusion granulation, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as large size, small water flow resistance, and restriction of biofilm effect , to achieve the effect of increasing contact and action opportunities and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

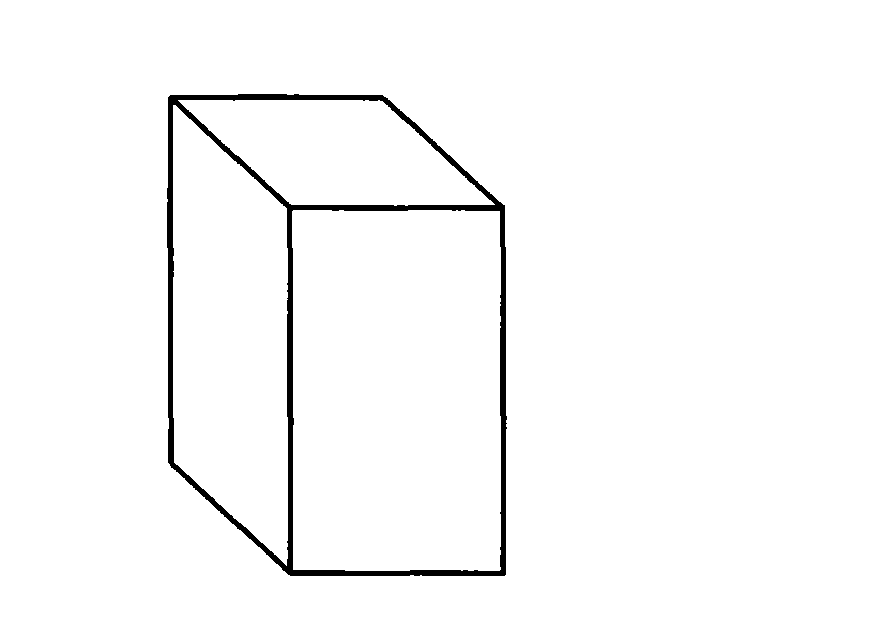

[0011] see figure 2 , The ceramsite of the present invention is to change the spherical shape in the prior art into other non-circular shapes of different spherical shapes. The so-called non-circular shape refers to other three-dimensional shapes except spherical shape.

[0012] According to the convenience of processing and preparation, various prisms can usually be used, preferably polygonal prisms such as regular triangular prisms and regular quadrangular prisms, especially regular polygonal prisms, which are easy to process and can well meet the requirements of use.

[0013] For ease of use, the edges on the ceramsite can be smooth, and the surface of the ceramsite can be rough. These structural features can be realized by grinding the surface of the ceramsite.

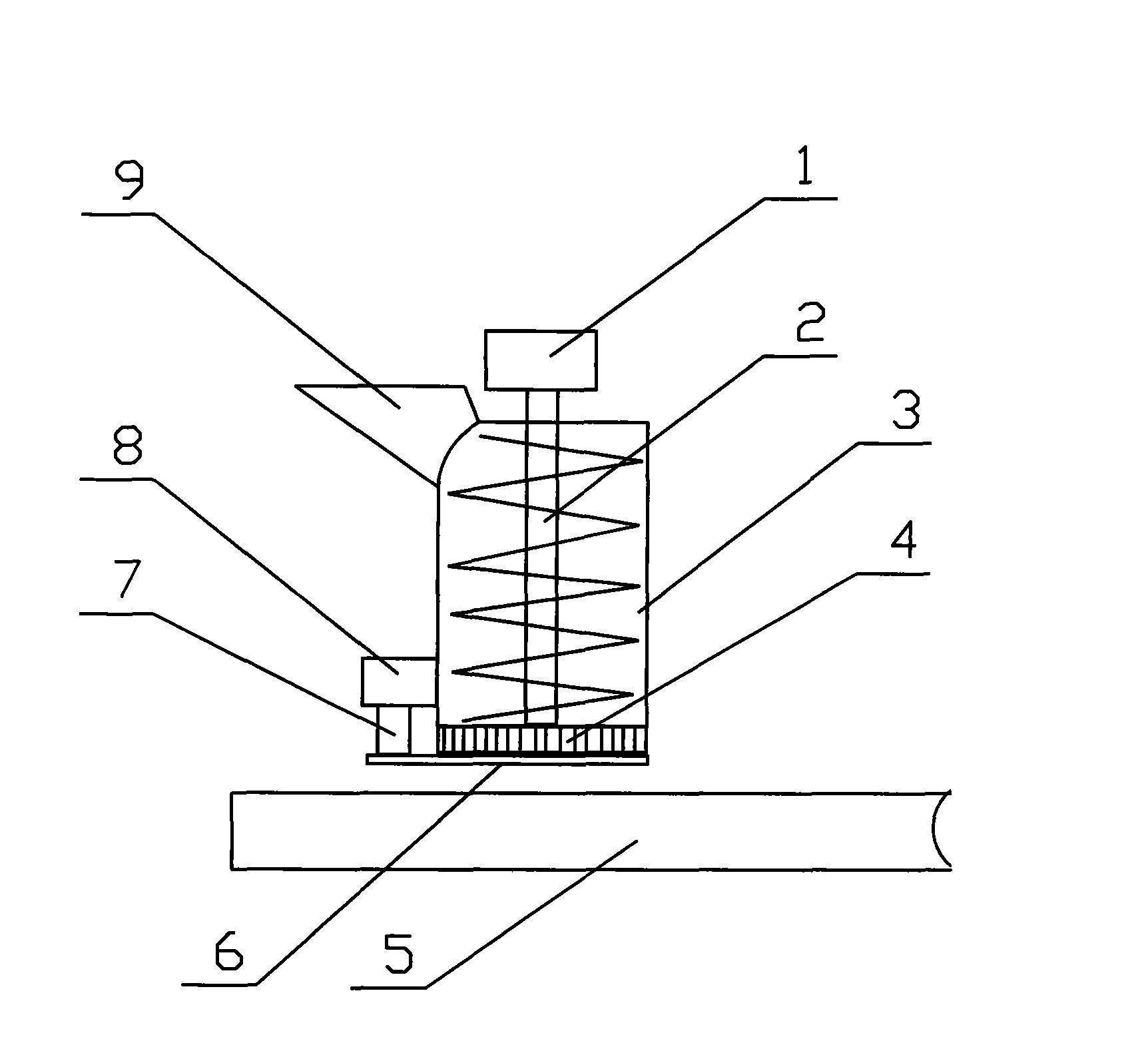

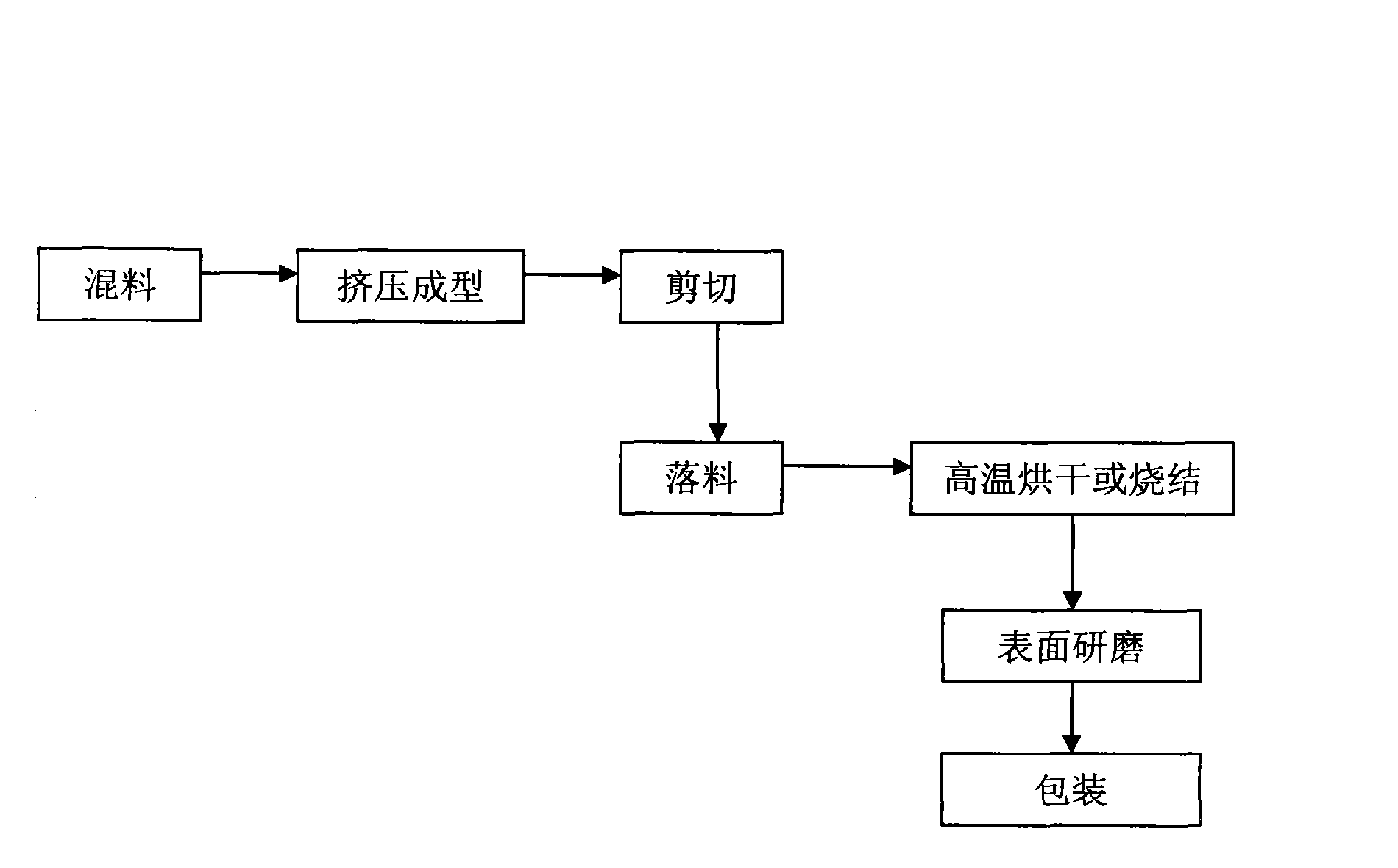

[0014] The present invention can use various suitable materials and formulas to prepare ceramsite. Since the main feature of the present invention is the shape of ceramsite, most of the existing processes can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com