Method for preparing purine nucleoside phosphorylase by solid state fermentation

A technology of purine nucleoside phosphorylase and solid-state fermentation, which is applied in the field of preparing purine nucleoside phosphorylase by solid-state fermentation, and can solve the problems of improving the activity of purine nucleoside phosphorylase products, demanding equipment and operating techniques, and taking a long time. , to achieve the effect of less time-consuming, high production efficiency and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

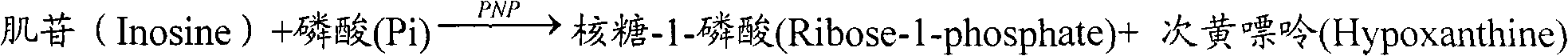

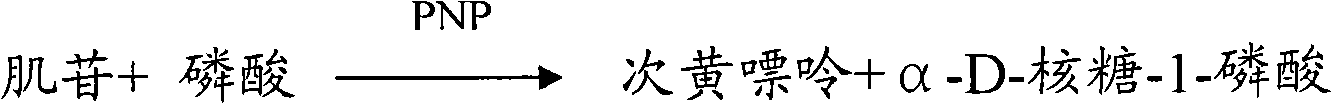

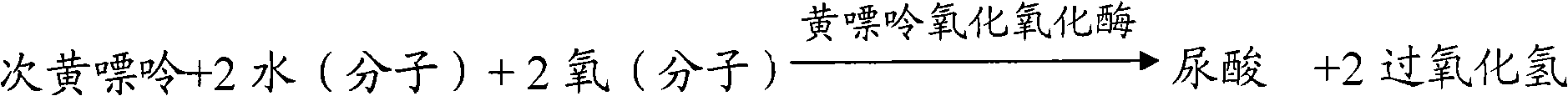

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] This example illustrates the method for preparing purine nucleoside phosphorylase by solid-state fermentation of the present invention.

[0141] 1. Preparation of Bacillus subtilis seed liquid:

[0142] Under aseptic conditions, use a pipette to rinse the purchased ACCC 10741 slant with 5 ml of sterile normal saline, absorb the resulting washing solution, add it to 45 ml of sterile normal saline and shake to make a bacterial suspension. Take 5 milliliters of the bacterium suspension and insert it into 50 milliliters of liquid seed culture medium, shake the shaker at 37 ° C and 150 rpm for 6 hours, and then obtain a turbid first-stage seed liquid, which is obtained by cell counting. The cell density was 1.2 x 10 5 cells / ml.

[0143]Get the first-stage seed liquid, and inoculate it into two 1000-milliliter culture bottles containing 300 ml of seed culture medium with an inoculum amount of 20 milliliters per bottle. After cultivating on a shaking table for 10 hours, one...

Embodiment 2

[0174] Cultivate ACCC 10741 according to the method of Example 1, the difference is that the bacterial suspension obtained by washing the strains preserved on the slant with sterile physiological saline is heated to 68° C. in a water bath within 1 minute and incubated for 15 minutes, and cooled within 2 minutes. to 37°C; then cultured on a shaker at 37°C and 150 rpm for 5 hours to obtain a turbid first-stage seed solution, and the cell density obtained by cell counting was 2.9×10 6 cells / ml. Obtain 22 grams of purine nucleoside phosphorylase dry powder. The specific activity of the obtained purine nucleoside phosphorylase is 1.00KU / gram. The yield of this embodiment is 10KU / kg solid fermentation medium liquid part.

Embodiment 3

[0176] This example illustrates the method for preparing purine nucleoside phosphorylase by solid-state fermentation of the present invention.

[0177] 1. Preparation of Bacillus subtilis seed liquid:

[0178] Under aseptic conditions, use a pipette to rinse the purchased ACCC 10741 slant with 5 ml of sterile normal saline, absorb the resulting washing solution, add it to 45 ml of sterile normal saline and shake to make a bacterial suspension. Take 5 milliliters of the bacterium suspension and insert it into 50 milliliters of liquid seed culture medium, shake it at 35 DEG C and 180 rpm for 8 hours, and then obtain a turbid first-stage seed liquid, which is obtained by cell counting. The cell density was 1.1 x 10 5 cells / ml.

[0179] Get the first-stage seed liquid, and inoculate it into two 1000-milliliter culture bottles containing 300 ml of seed culture medium with an inoculum volume of 20 milliliters per bottle. After cultivating on a shaking table for 10 hours, one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com