Nitrogen sealing device

A nitrogen sealing and nitrogen technology, applied in the sealing, packaging, engine components and other directions of the engine, can solve the problems of external leakage of harmful and flammable gases, personal casualties, accidents, etc., to prevent spontaneous combustion and explosion, easy assembly and disassembly, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

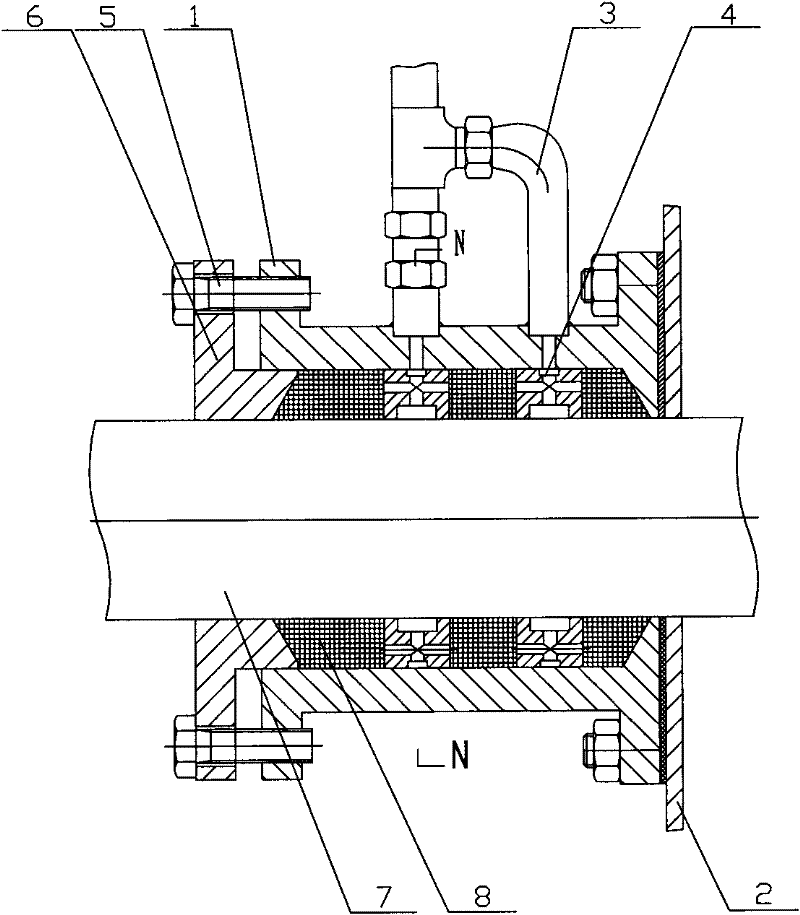

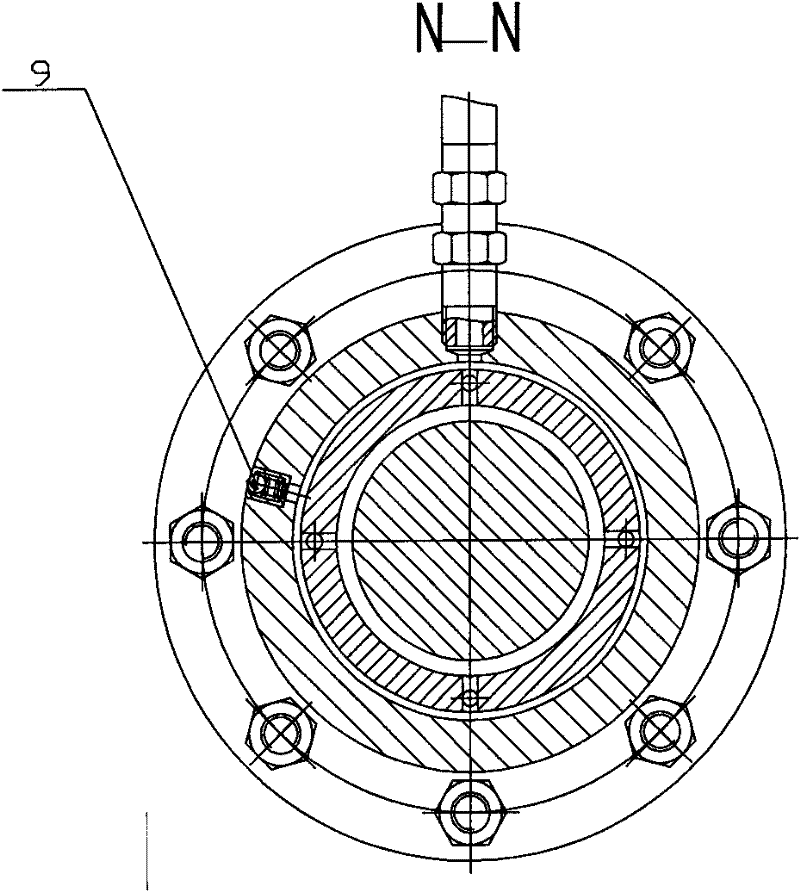

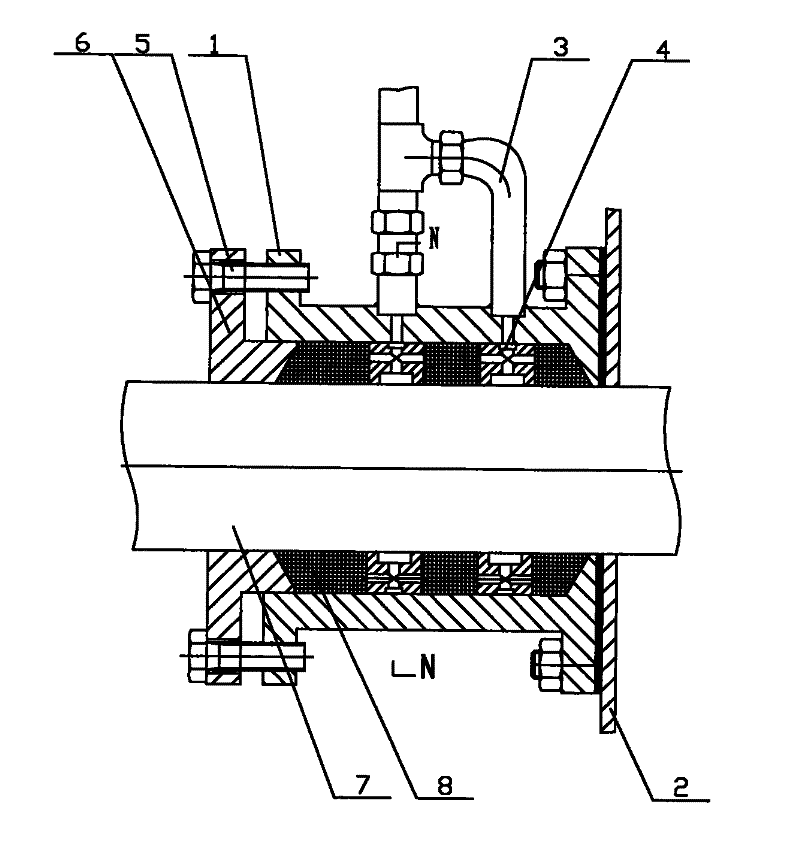

[0012] Such as figure 1 with figure 2 As shown, a nitrogen sealing device includes a packing seat 1, a cover plate 2 connected to the packing seat 1 through a compression bolt 5, an oil nozzle 9 is provided on the packing seat 1, an oil-immersed The packing 8 and the stuffing seat 1 are provided with a plurality of inflatable rings 4 , and the air intake pipe 3 is connected with the inflatable rings 4 .

[0013] The number of said inflatable rings 4 is two.

[0014] The inflatable ring 4 is filled with nitrogen.

[0015] The nitrogen pressure is 0.01-0.03 MPa higher than the gas pressure in the tank.

[0016] A nitrogen sealing device is installed at the driving end and the tail rotating shaft of the screw conveyor, and the nitrogen sealing device is fixed on the casing at both ends of the screw conveyor, and the two inflatable rings 4 are installed between the packing seat 1 and the rotating shaft 7 . The outer annular groove of the inflatable ring 4 is aligned with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com