Indirect heating type testing method of high temperature resistance of carbon/carbon heaters

A heating element, heating technology, applied in radiation pyrometry, measurement of resistance/reactance/impedance, measurement of electrical variables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

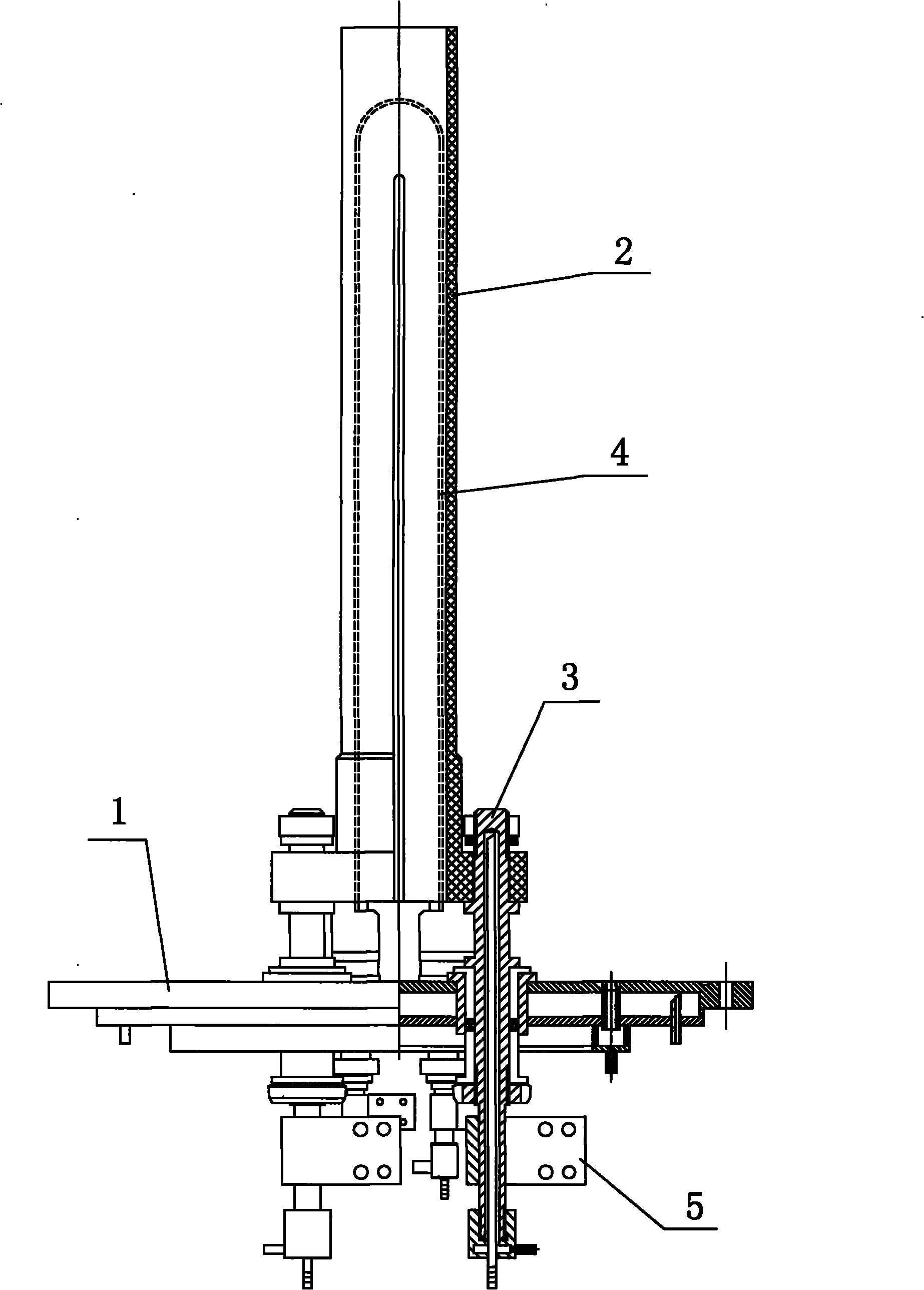

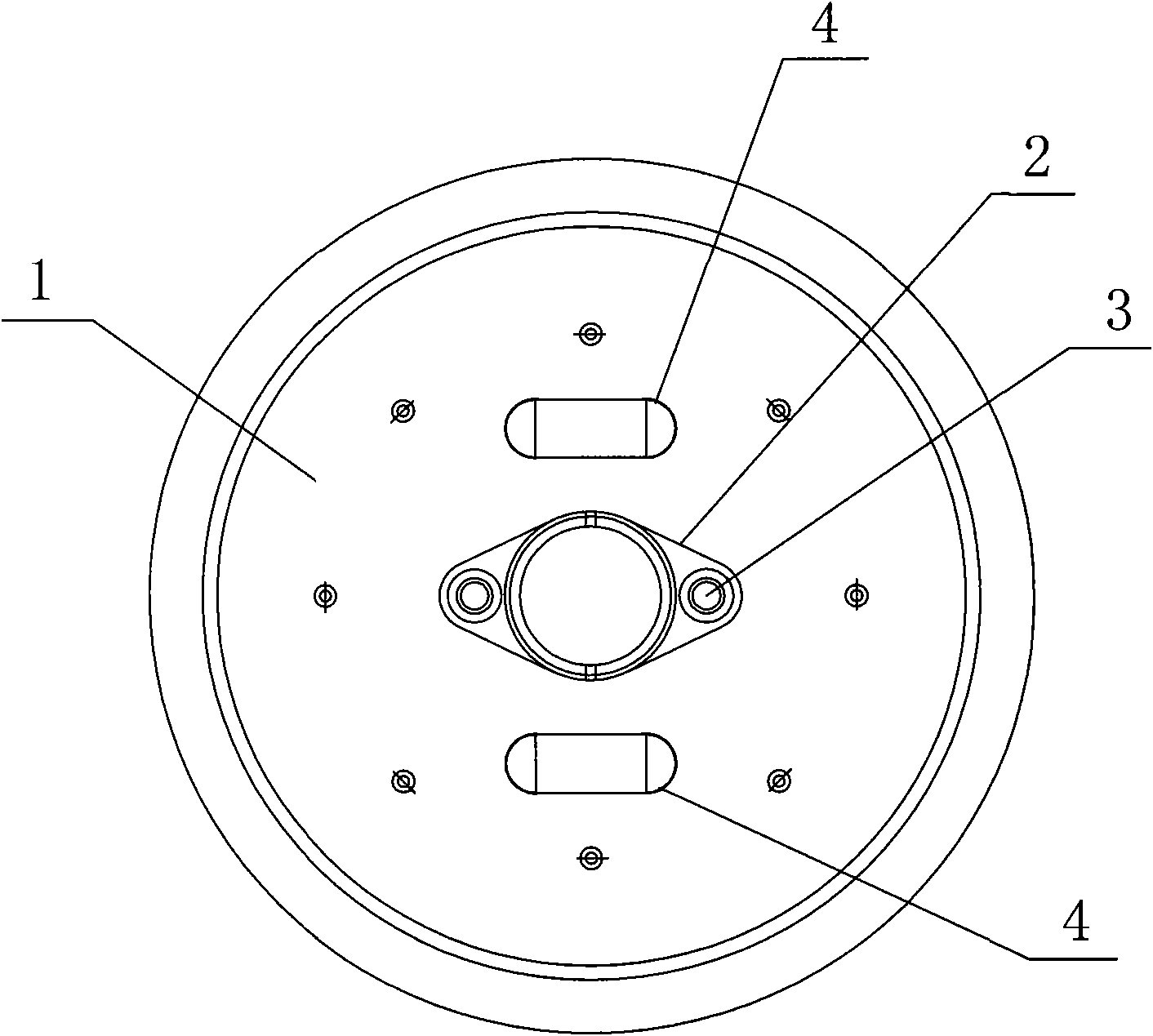

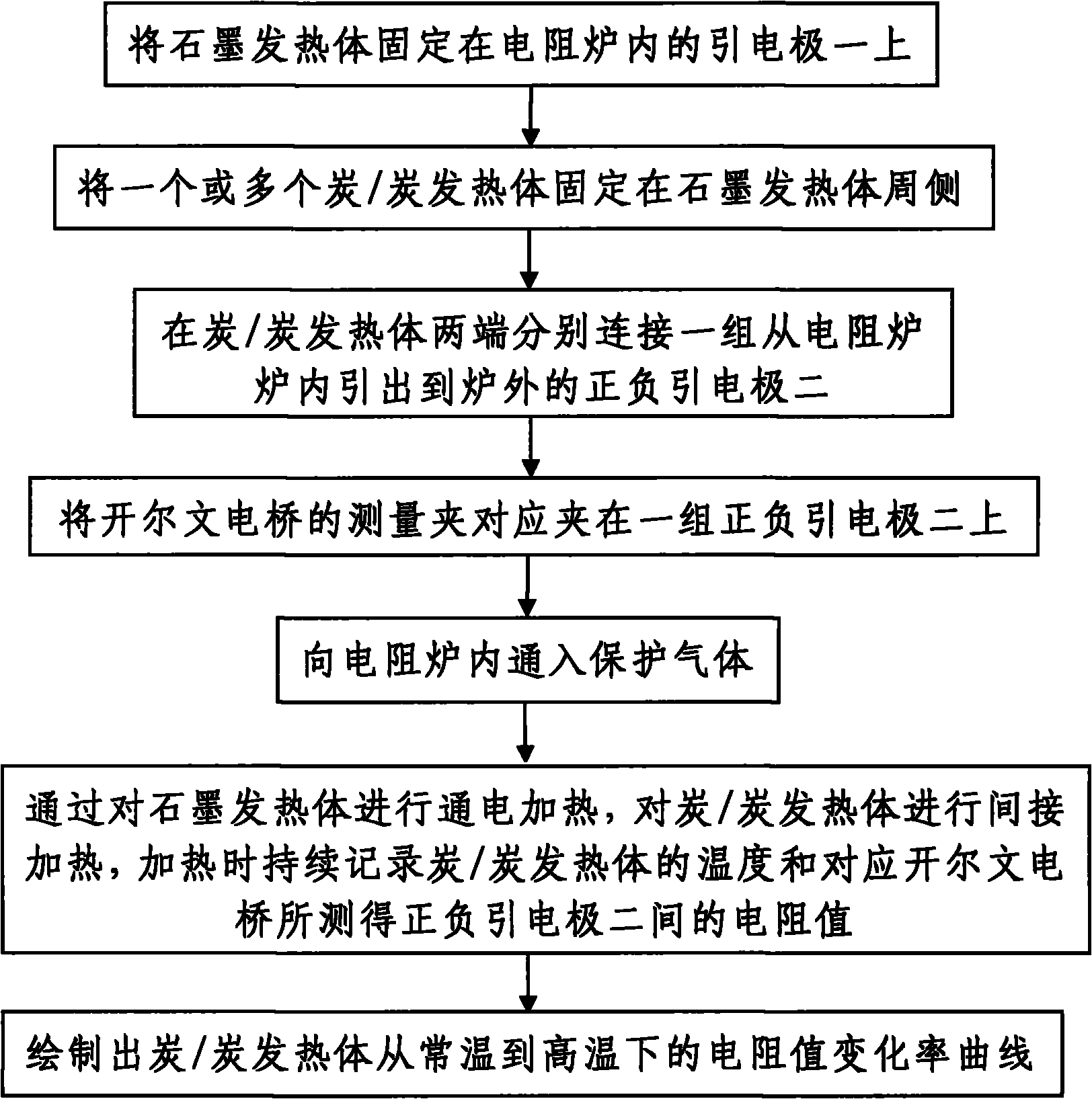

[0032] Such as figure 1 , figure 2 and image 3 As shown, the method for the indirect heating test charcoal / charcoal heating element high temperature resistance of the present invention comprises the following steps:

[0033] Step 1. The two ends of the graphite heating element 2 are fixedly connected to the positive and negative leading electrodes-3 in the resistance furnace, and the positive and negative leading electrodes-3 are arranged on the furnace bottom 1 of the resistance furnace.

[0034] In this embodiment, the shape of the graphite heating element 2 is U-shaped and is vertically fixed in the resistance furnace by bolts. Specifically, the two ends of the graphite heating element 2 are respectively fixed on the positive and negative electrodes-3. . The furnace body of the resistance furnace is a sealed furnace body continuously cooled by circulating water.

[0035] Step 2: Fix the tested charcoal / charcoal heating element 4 on the side of the graphite heating ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com