Power transmission bus and bus assembly thereof

A technology of power transmission and busbar, which is applied in the field of busbar and its busbar components, and can solve problems such as unspecified connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] (Embodiment 1, bus bar for power transmission)

[0102] See Figure 21 , The bus bar for power transmission in this embodiment includes an aluminum bar 3 and two copper-aluminum connecting structural members. The two copper-aluminum connecting structural parts are divided into a first copper-aluminum connecting structural part 1 and a second copper-aluminum connecting structural part 2 .

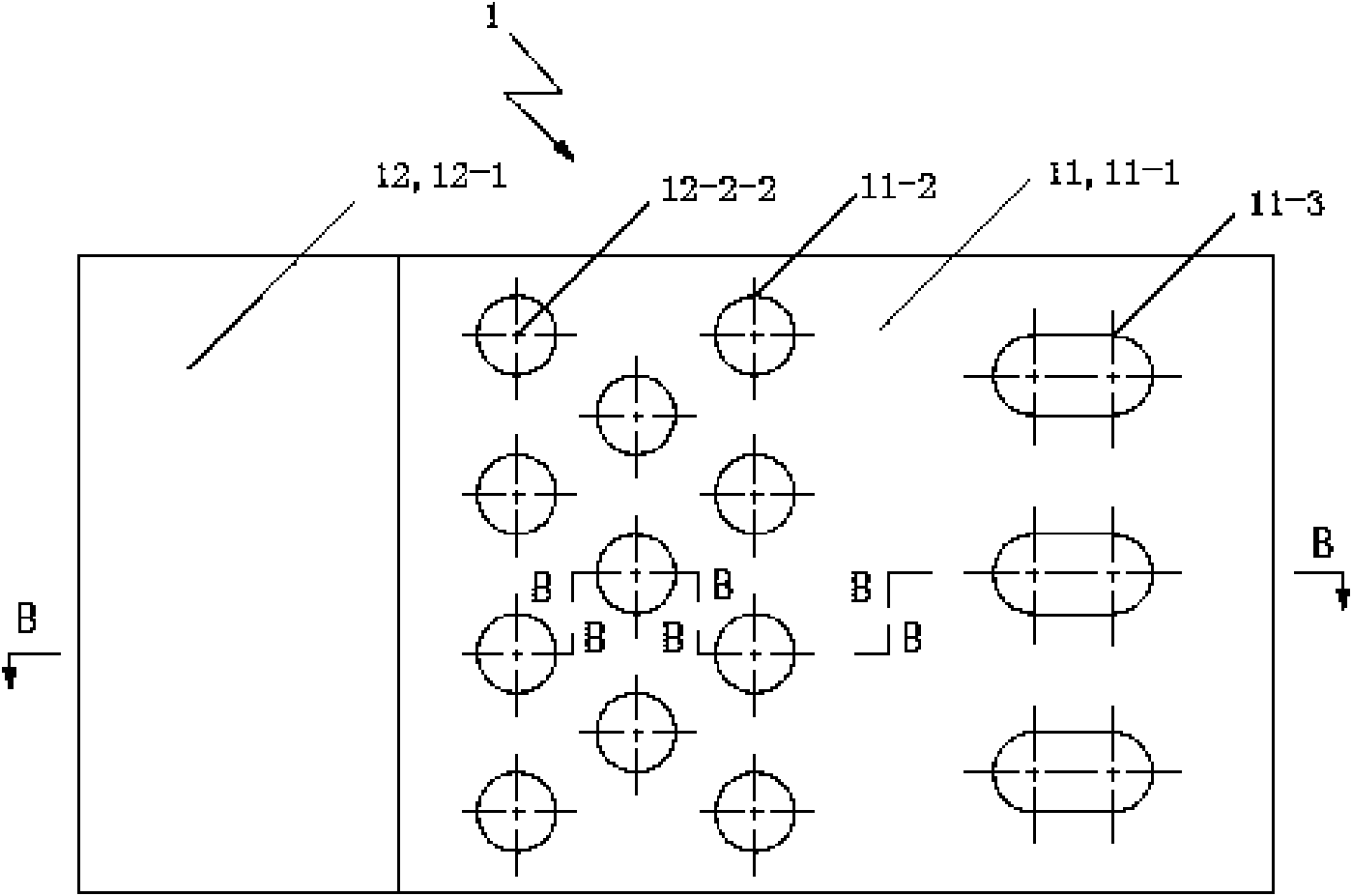

[0103] See image 3 and Figure 4 The first copper-aluminum connection structure 1 includes a first copper plate 11 and a first cast aluminum plate 12 obtained by casting the first copper plate 11 as an insert.

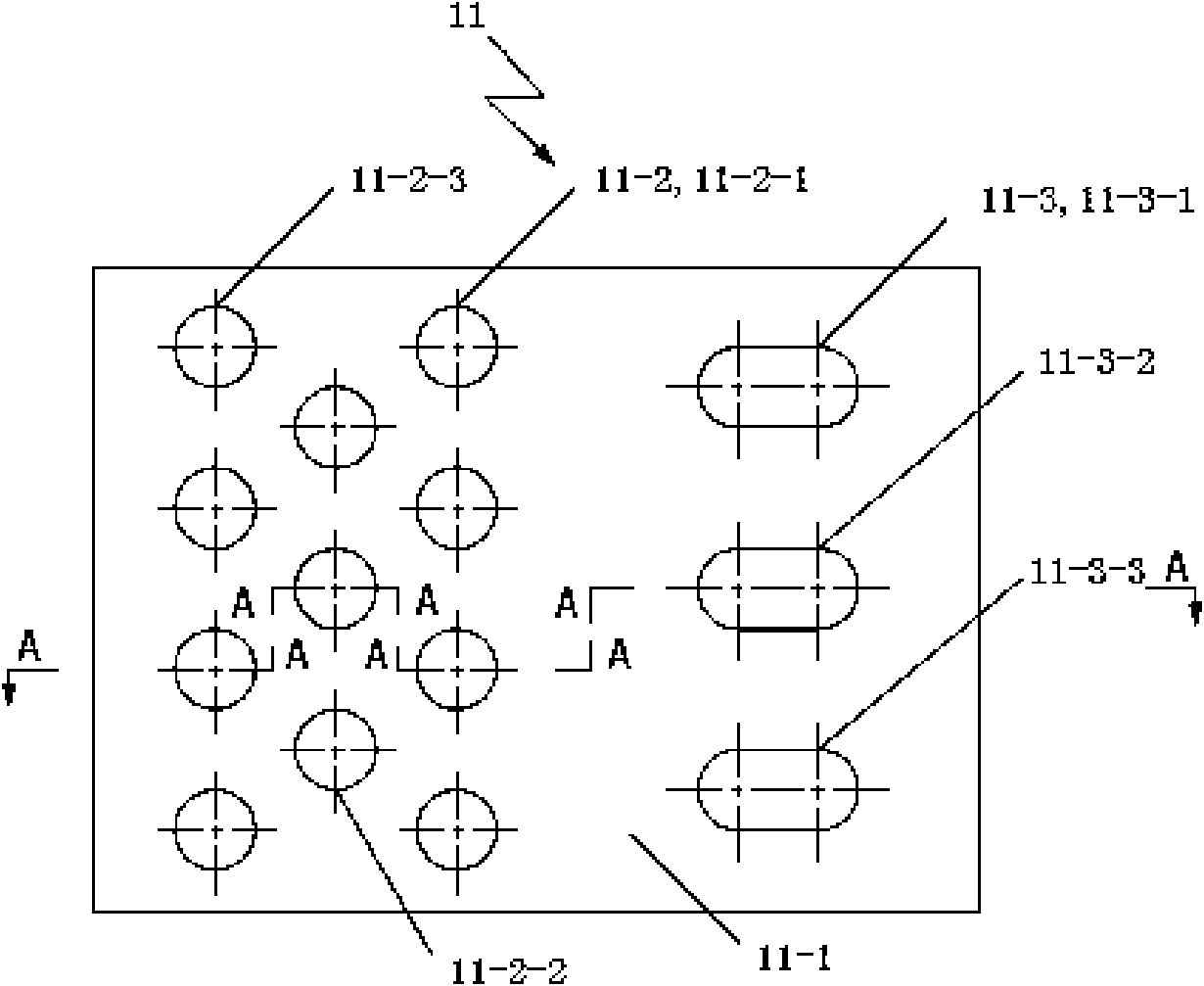

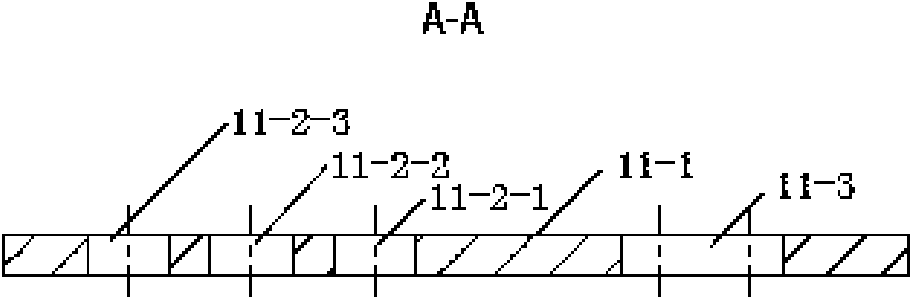

[0104] See figure 1 and figure 2 , the first copper plate 11 is a stamped pure copper rectangular plate with a thickness of 3 to 5 millimeters (4 millimeters in this embodiment), which includes the first pure copper plate body 11-1, and is set on the first pure copper plate body 11-1 11 connection holes 11-2 on the left and three bolt holes 13 on the right on the first...

Embodiment 2

[0122] (Embodiment 2, bus bar for power transmission)

[0123] The remaining parts of the busbar for power transmission in this embodiment are the same as in Embodiment 1, the difference is that:

[0124] See Figure 7 and Figure 8 , the thickness of the first copper plate 11 of the first copper-aluminum connection structure 1 is 5 to 10 mm (8 mm in this embodiment). The first copper plate 11 also includes a connection groove 11-4. Two connection grooves 11-4 are arranged on the left and right sides, and are divided into a right connection groove 11-4-1 and a left connection groove 11-4-2. The right connecting groove 11-4-1 is opened on the first pure copper plate body 11-1, and is located on the front side of the first pure copper plate body 11-1, and coincides with the position of the first group of connecting holes 11-2-1, The width is slightly wider than the diameter of the first group of connecting holes 11-2-1. The left connection groove 11-4-2 is opened on the firs...

Embodiment 3

[0128] (Embodiment 3, bus bar for power transmission)

[0129] The remaining parts of the busbar for power transmission in this embodiment are the same as in Embodiment 1, the difference is that:

[0130] See Figure 5 and Image 6 , when the first cast aluminum plate 12 is cast, the left end of the first pure copper plate body 11-1 is covered in the first cast aluminum plate 12 from the front; thus the first cast aluminum joint of the first cast aluminum plate 12 12-2 not only includes the first cast aluminum connecting plate 12-2-1 and the connecting column 12-2-2, but also includes the first cladding connecting plate 12-2-4. The first cladding connecting plate 12-2-4 is formed simultaneously with the connecting column 12-2-2 to form a whole, and the rear side of the first cladding connecting plate 12-2-4 is densely connected to the first pure copper plate On the front side of the left part of the body 11-1. The front end surface of the first cladding connecting plate 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com