Greening soilless lawn for roof surface, production method and using method thereof

A soilless lawn and controller technology, applied in the direction of soilless cultivation, botany equipment and methods, applications, etc., can solve problems such as increasing construction costs, increasing building load-bearing, and damaging waterproof layers, so as to eliminate noise and improve air quality. Humidity, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

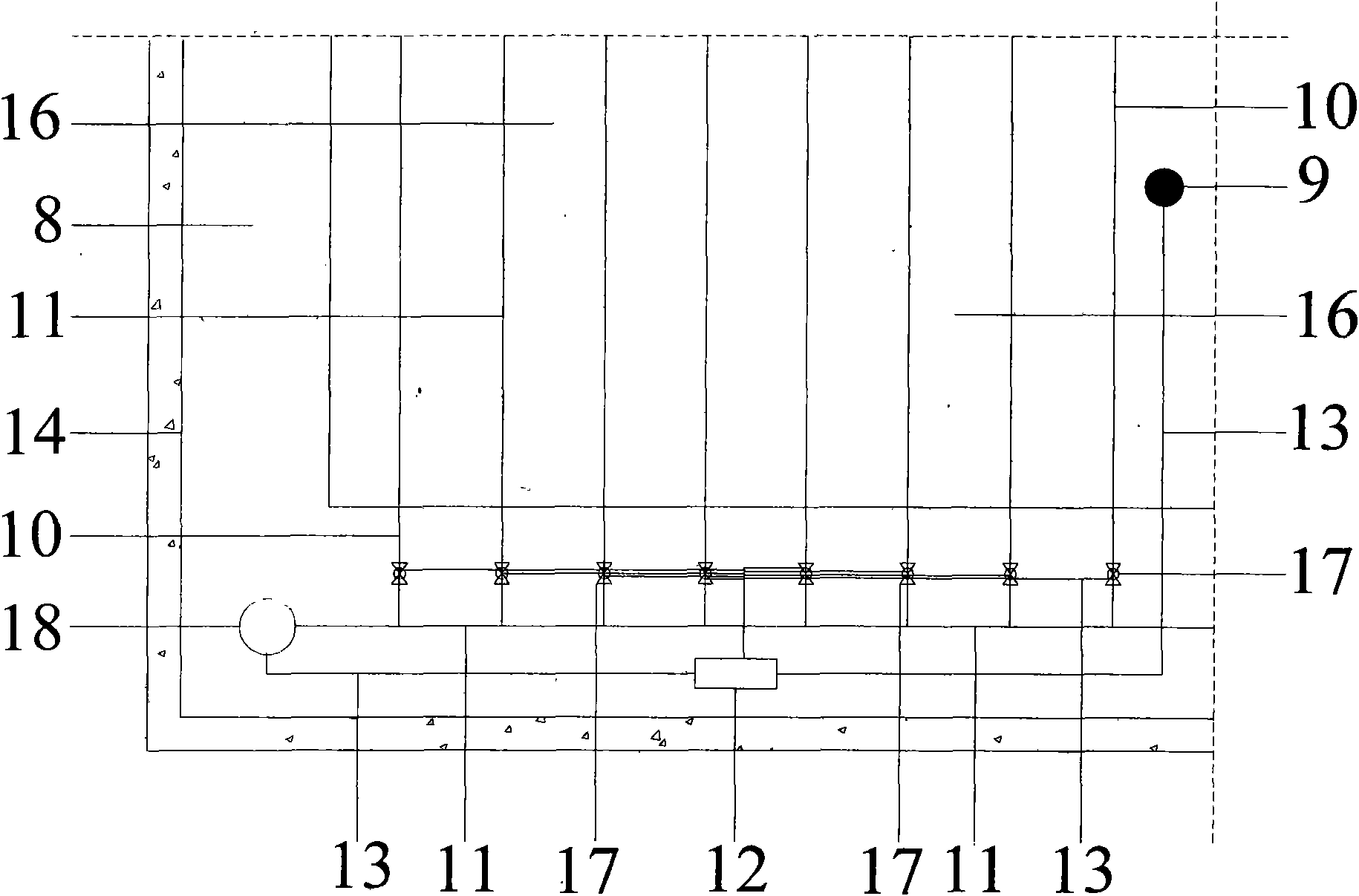

[0053] It is composed of a soilless lawn main body (16), a root layer (7), a humidity sensor (9), a branch pipe (10), a main pipe (11), a shut-off valve (17) and a main controller (12). A root-separating layer (7) is set on the roof floor (8) in the wall (14), and the root-separating layer (7) prevents plant roots from destroying the surface of the roof floor (8), and the root-separating layer (7) is covered with a soilless lawn Main body (16), main pipe (11) is connected with branch pipe (10) in the pipeline layer (4) of soilless lawn main body (16), and shut-off valve (11) is set between branch pipe (10) and main pipe (11) 17), the shut-off valve (17) controls the main pipe (11) to deliver the water source to the branch pipe (10), the shut-off valve (17) is connected with the main controller (12) through the information control line (13), and receives the main controller (12 ) instructions.

[0054] Place at least one humidity sensor (9) in the soilless lawn main body (16),...

Embodiment 2

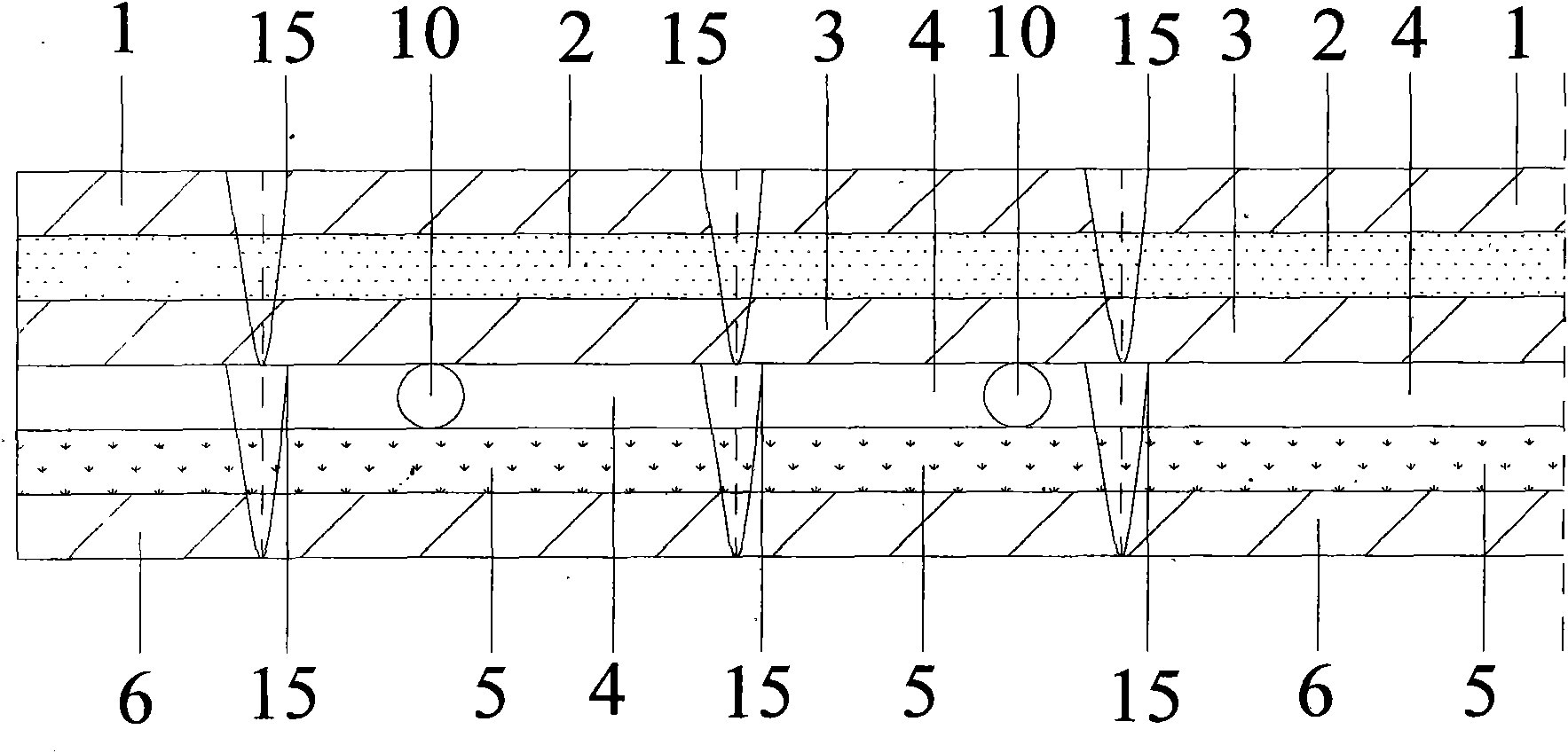

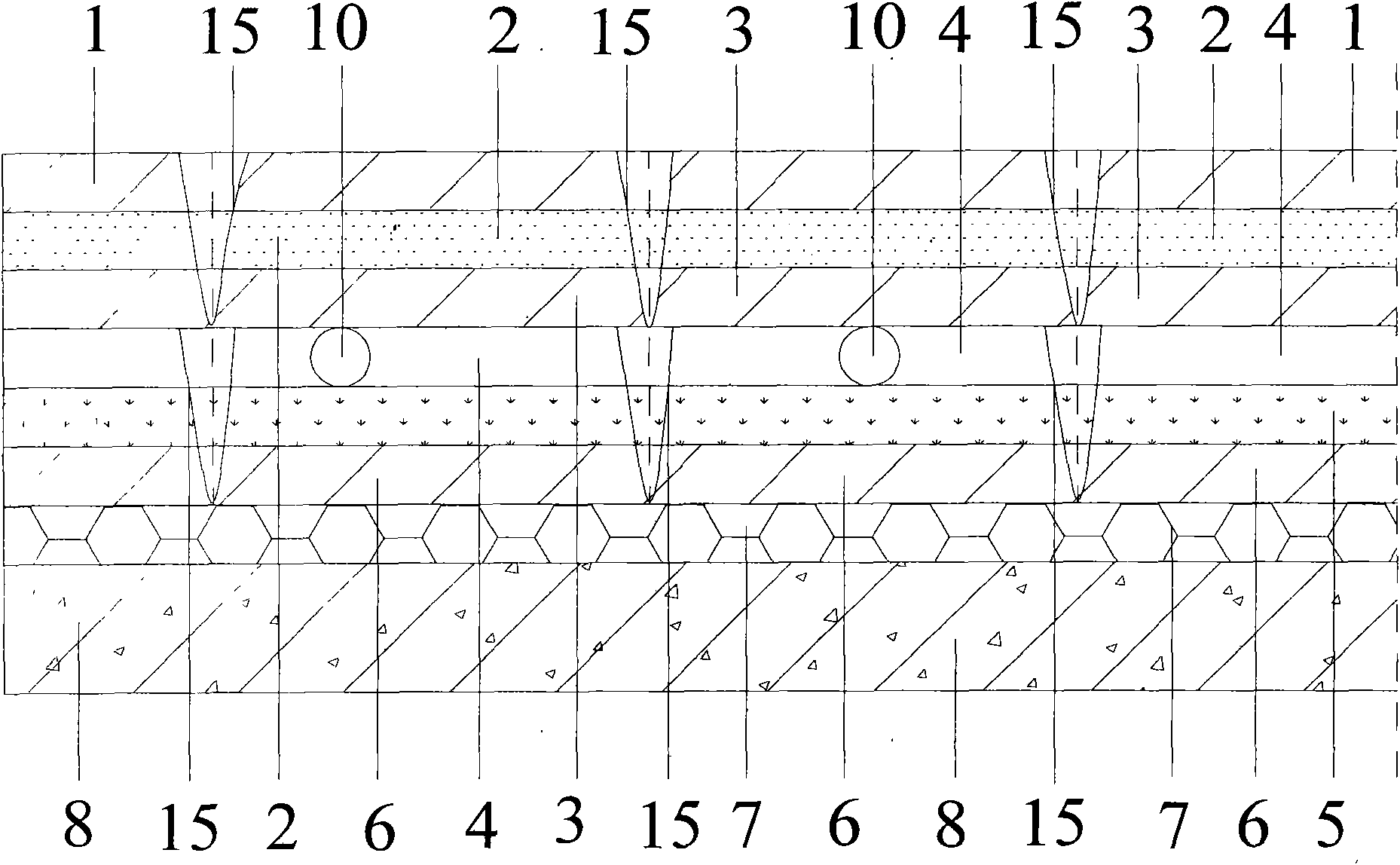

[0057] The main body (16) of the soilless lawn is composed of a protective layer (1), a plant layer (2), a plant growth base (3), a pipeline layer (4), a nutrient and water retention layer (5) and a bottom protection layer (6), Plant layer (2), plant growth layer (3), pipeline layer (4) and nutrient water retention layer (5) are set between protective layer (1) and bottom protective layer (6), bottom protective layer (6) and A nutrient and water retention layer (5) and a pipeline layer (4) are arranged between the plant growth layers (3), a nutrient and water retention layer (5) is arranged on the bottom protective layer (6), and peat and water retaining agent are placed in the nutrient and water retention layer (5) And slow-release fertilizer, the ratio is 100:20:1, keep moisture and provide nutrient for the plant of plant layer (2), pass branch pipe (10) and peat, water retention through bottom protective layer (6) and plant growth layer (3) The agent and the slow-release fe...

Embodiment 3

[0062] The protective layer (1), the plant growth layer (3) and the bottom protective base (6) of the soilless lawn main body (16) are made of geotextiles or animal and plant fibers or waste quilt materials, and on the bottom protective base (6) Make the nutrient water retention layer (5), the nutrient water retention layer (5) is formed by mixing peat, water retention agent and slow-release fertilizer in a ratio of 100:20:1, spread on the bottom protection layer (6) to form the nutrient water retention layer (5), peat and slow-release fertilizer provide nutrients for plant growth, and water-retaining agent keeps water for plant growth and reduces water evaporation loss.

[0063] Lay branch pipes (10) on the nutrient water-retaining layer (5) to form the pipeline layer (4), and drip pipes are arranged at intervals on the branch pipes (10), and the branch pipes (10) are made of polyethylene materials, and the soilless lawn main body ( 16) Transport water and nutrients.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com