Selenium-rich nano-silver active carbon filter element and preparation method thereof

A nano-silver activated carbon and filter element technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as increasing calcium loss, and achieve the effects of ensuring health and safety and preventing selenium deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

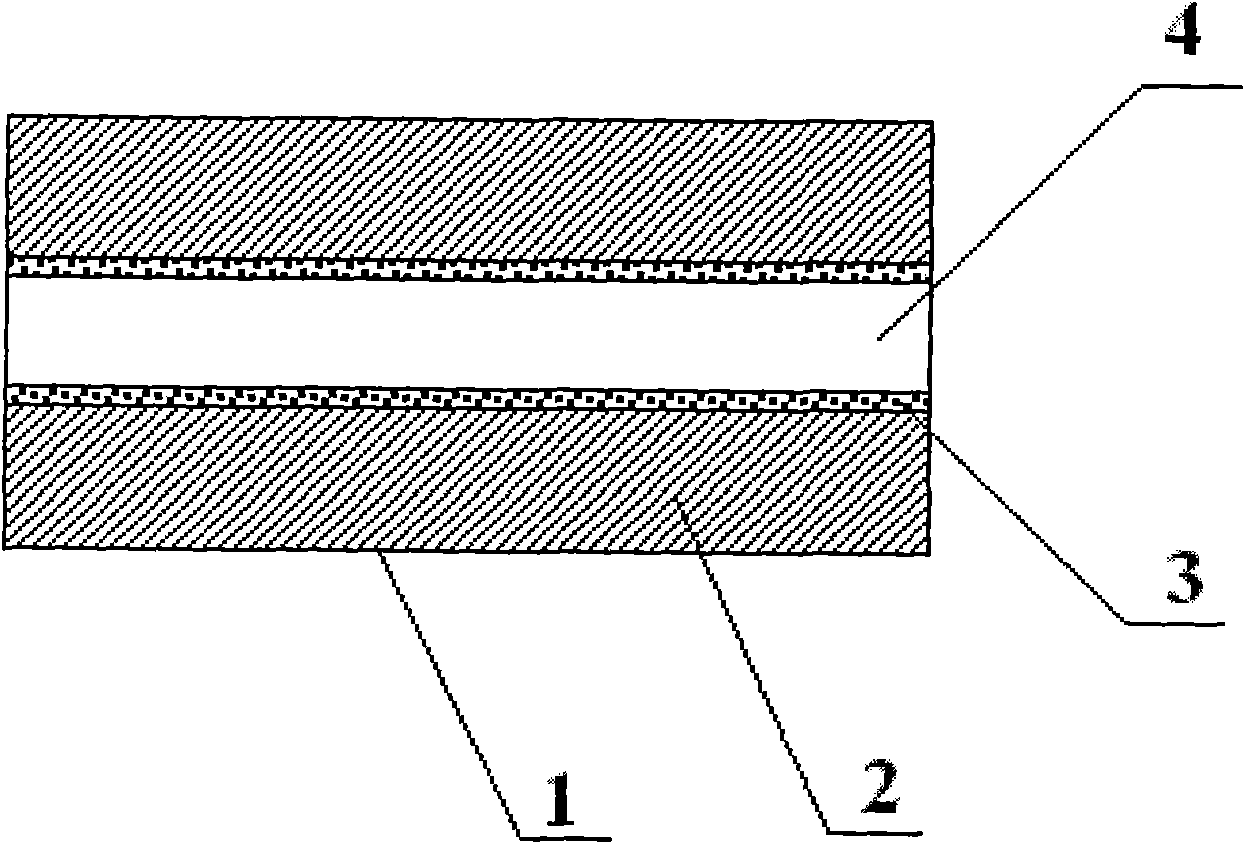

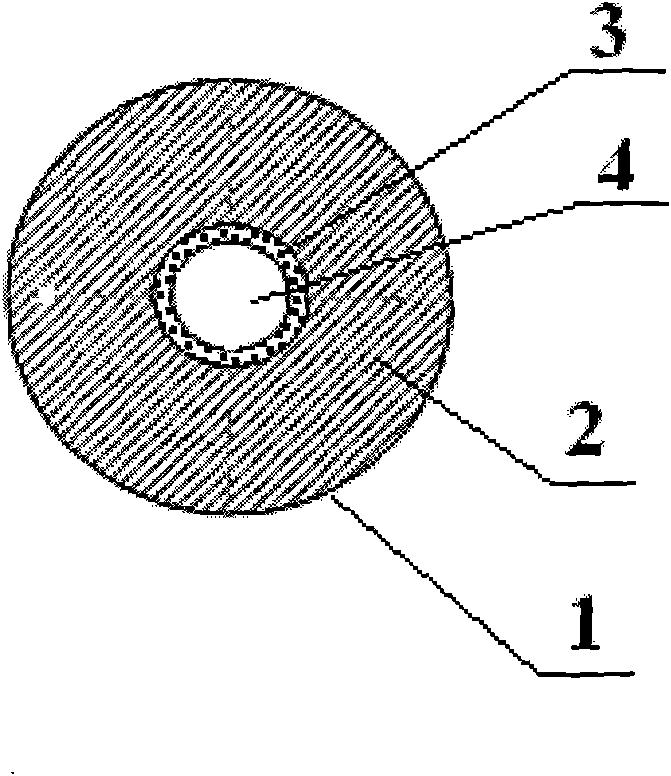

[0040] Such as figure 1 , figure 2 As shown, the selenium-enriched nano-silver activated carbon filter element of the present invention is composed of an outer envelope material 1, a nano-silver activated carbon filter layer 2, a selenium-enriched particle layer 3 and a water passage cavity 4 in the center of the filter element.

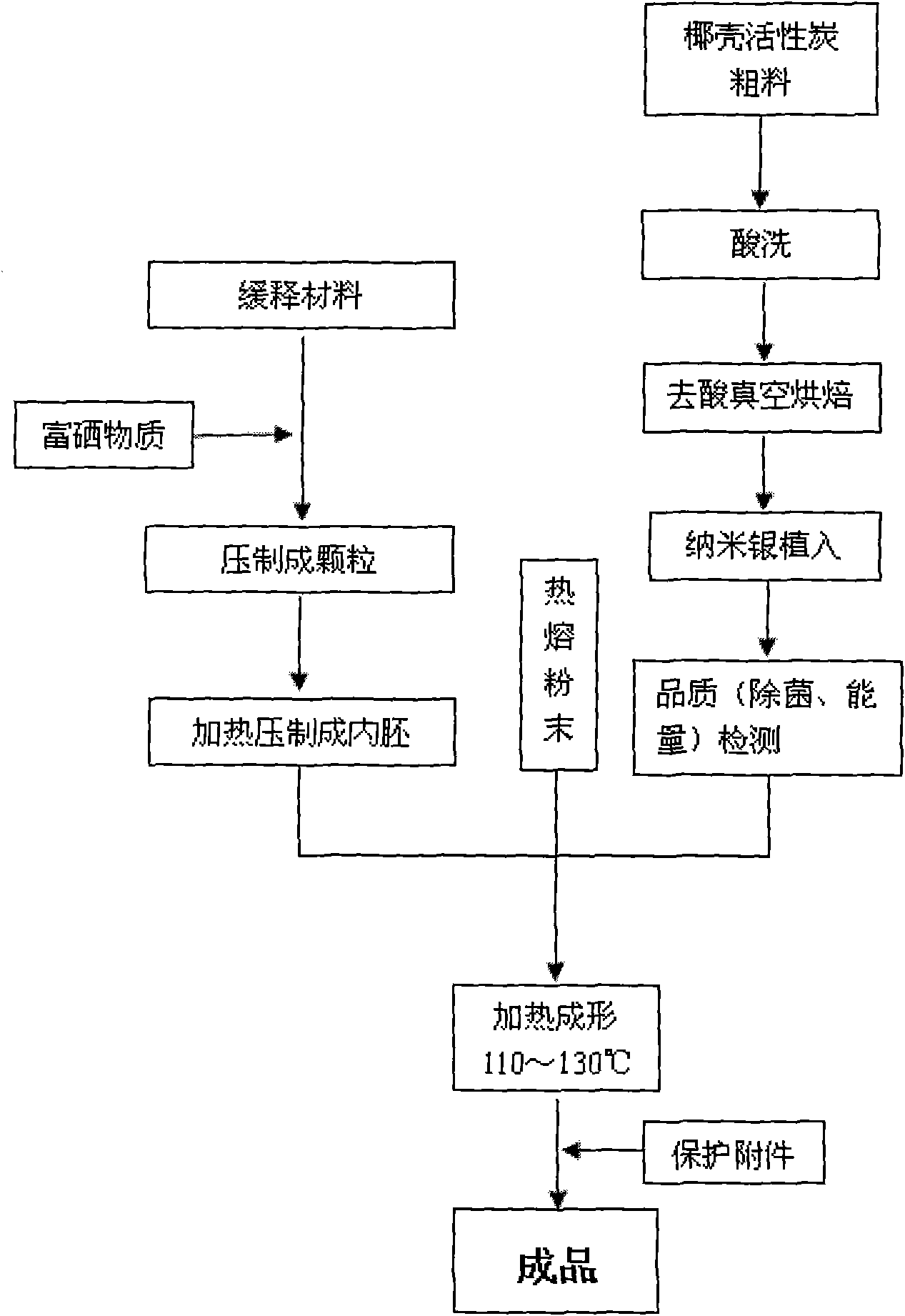

[0041] according to image 3 Shown flow chart, according to following weight percentage proportioning:

[0042] 20-50nm nano-silver 0.15-3%

[0044] Coconut Shell Activated Carbon Balance

[0045] The coconut shell activated carbon is pickled with dilute hydrochloric acid in a reaction kettle, and after centrifugation and dehydration, it is baked in a vacuum container to constant weight, cooled to room temperature, implanted with 20-50nm nano-silver, and the iodine value of the product is detected > 1000mg / g, sterilization rate ≥ 95%, far-infrared normal total emission rate ≥ 0.8, negative ion concentration ≥ 6000 / c...

Embodiment 2

[0050] Mix 60 grams of methacrylic acid copolymer powder, 18 grams of chitosan selenite and 42 grams of calcium selenite, press to form porous skeleton particles, and then make tubular selenium-enriched granular layer endoderm.

[0051] Prepare nano-silver activated carbon and hot-melt powder mixture according to the following weight percentage ratio:

[0052] 20~50nm nano silver 3%

[0053] Polyethylene hot melt powder 8%

[0054] Coconut Shell Activated Carbon Balance

[0055] The preparation method of the selenium-enriched nano-silver activated carbon filter element is the same as that in Example 1, except that after extrusion molding, it is set at a high temperature of 130° C. for 0.5 minutes.

Embodiment 3

[0057] Prepare nano-silver activated carbon and hot-melt powder mixture according to the following weight percentage ratio:

[0058] 20~50nm nano silver 0.2%

[0059] Polyethylene hot melt powder 7%

[0060] Coconut Shell Activated Carbon Balance

[0061] The preparation method of the selenium-enriched nano-silver activated carbon filter element is the same as that in Example 1, except that after extrusion molding, it is set at a high temperature of 120° C. for 1 minute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com