Bi-component copper-zirconium catalyst for deeply removing CO

A technology of copper-zirconium catalyst and carbon monoxide, applied in physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, chemical change purification/separation, etc., can solve high removal temperature and insufficient CO removal depth , short life and other problems, to achieve the effects of good catalytic performance, simplified preparation process, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

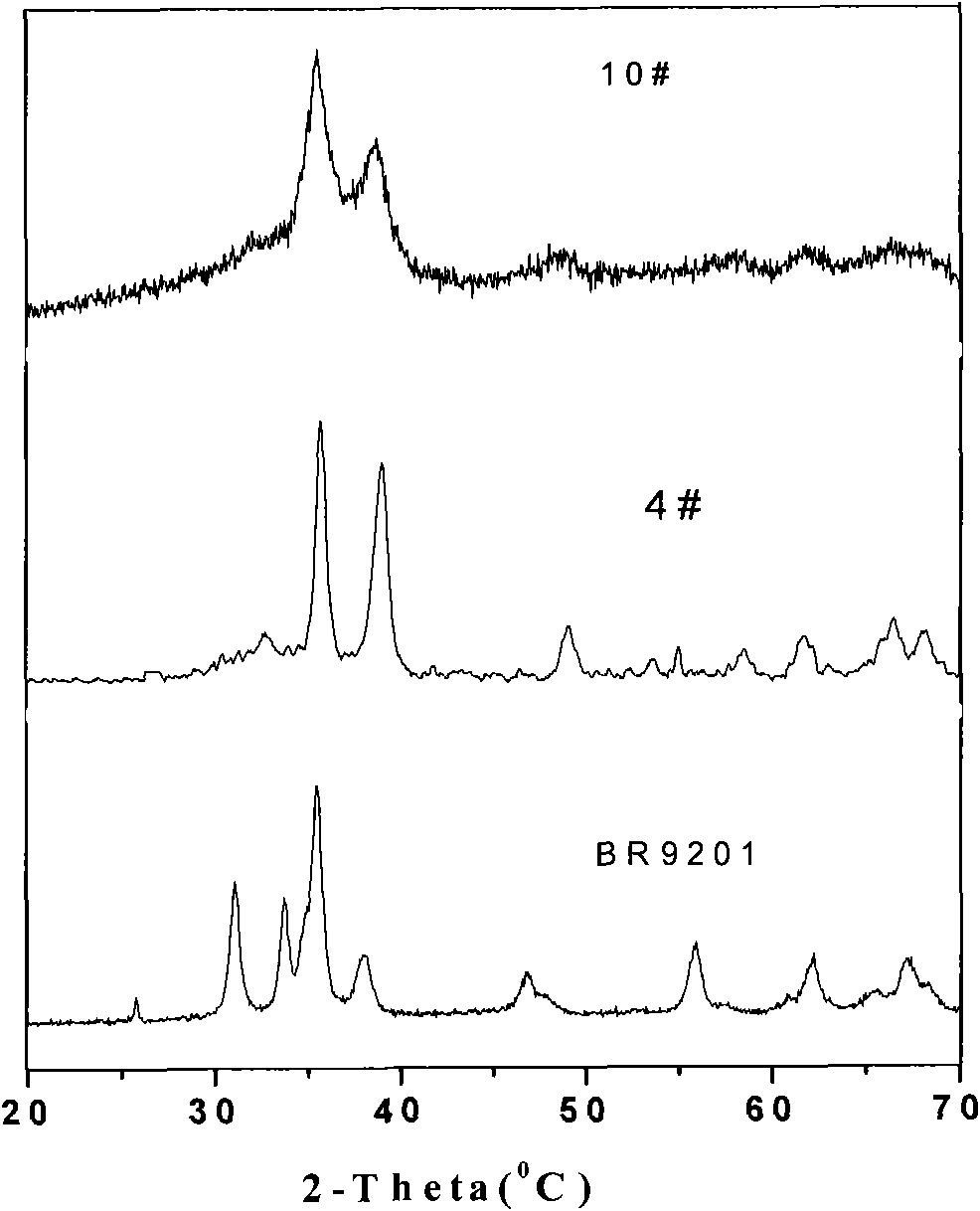

Embodiment 1

[0060] Catalysts were prepared using a co-current method.

[0061] Mix 716mL of 1 mol / liter copper nitrate solution and 24.3mL 1 mol / liter zirconium oxychloride solution evenly, then add the mixed solution and 1000mL 1 mol / liter sodium carbonate solution in parallel to a 2L container for For precipitation, the precipitation temperature is 90°C, and the pH value is controlled at 10.5±0.5. Then it was aged for 2 hours under vigorous stirring, and the aging temperature was 90°C. It was then filtered and washed at least six times with deionized water at 80 °C until Na 2 The O content is less than 0.05%. Dry at 110°C for 12 hours, and bake at 400°C for 6 hours. Made with 95% CuO and 5% ZrO 2 CuO / ZrO 2 Catalyst, marked 1 # catalyst. According to BET analysis, the specific surface area is 15m 2 / g.

Embodiment 2

[0063] The catalyst is prepared in the same manner as in Example 1, except that 678.8mL of 1 mol / liter of copper nitrate solution and 48.7mL of 1 mol / liter of zirconium oxychloride solution are mixed uniformly, and then the mixed solution is mixed with 1000mL of 1 mol / liter of The sodium carbonate solution per liter was added in parallel to a 2L container for precipitation, the precipitation temperature was 80°C, the pH value was controlled at 8.5±0.5, and the aging temperature was 80°C. Made with 90% CuO and 10% ZrO 2 CuO / ZrO 2 Catalyst, labeled 2 # catalyst. According to BET analysis, the specific surface area is 25m 2 / g.

Embodiment 3

[0065] The catalyst is prepared in the same manner as in Example 1, except that 603.4mL of 1 mol / liter of copper nitrate solution and 97.4mL of 1 mol / liter of zirconium oxychloride solution are mixed uniformly, and then the mixed solution is mixed with 1000mL of 1 mol / liter of The sodium carbonate solution per liter was added in parallel to a 2L container for precipitation, the precipitation temperature was 70°C, the pH value was controlled at 6.5±0.5, and the aging temperature was 70°C. Made with 80% CuO and 20% ZrO 2 CuO / ZrO 2 Catalyst, marked 3 # catalyst. According to BET analysis, the specific surface area is 55m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com