Production method of furfural with high purification rate and special apparatus therewith

A production method and technology for special equipment, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing and other directions, can solve the problems of increasing the production cost of furfural, low impurity removal rate, increasing the distillation load and cleaning frequency of the initial distillation column, and the like, Achieve the effect of improving enterprise economic benefits, enhancing purification effect and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A production method of furfural with a high purification rate. The biomass is pulverized and then mixed with acid and sent to a hydrolysis tank for hydrolysis. The furfural gas produced after hydrolysis is passed into the water for washing and purification. The purified furfural gas enters the initial distillation and rectification process, and rectification Finally, furfural products are obtained.

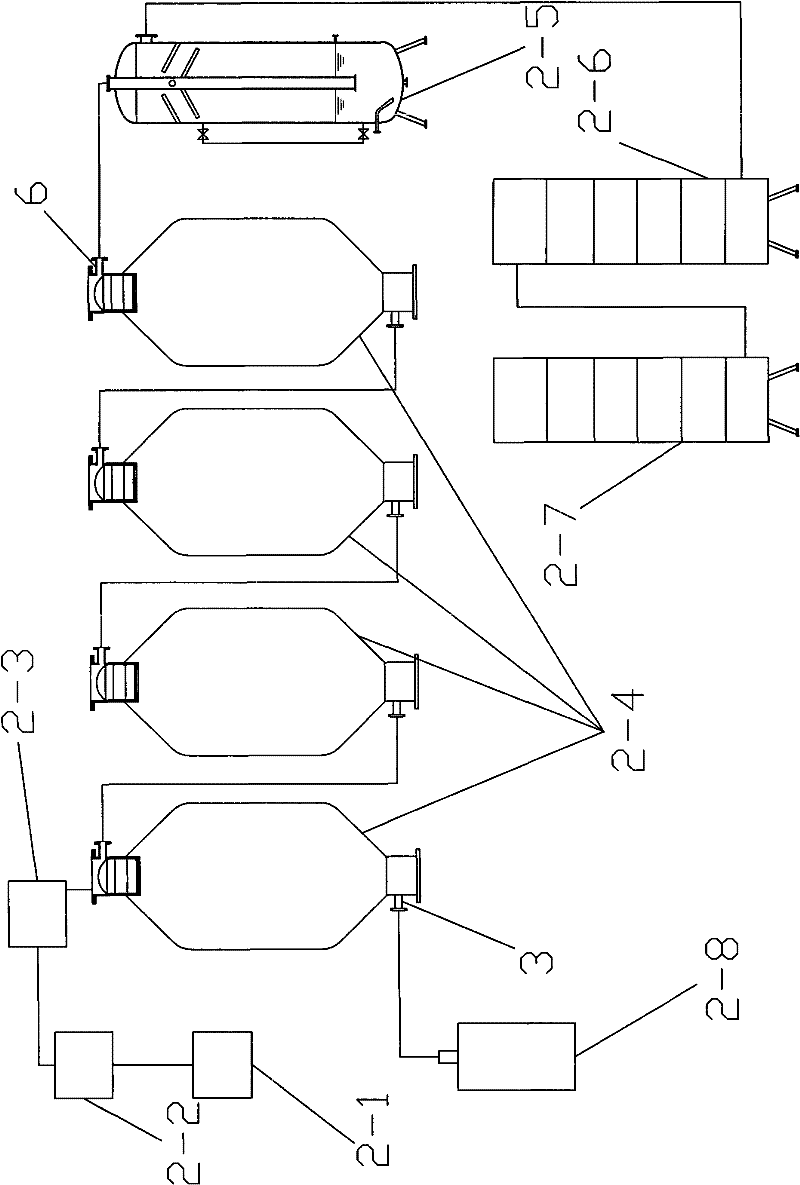

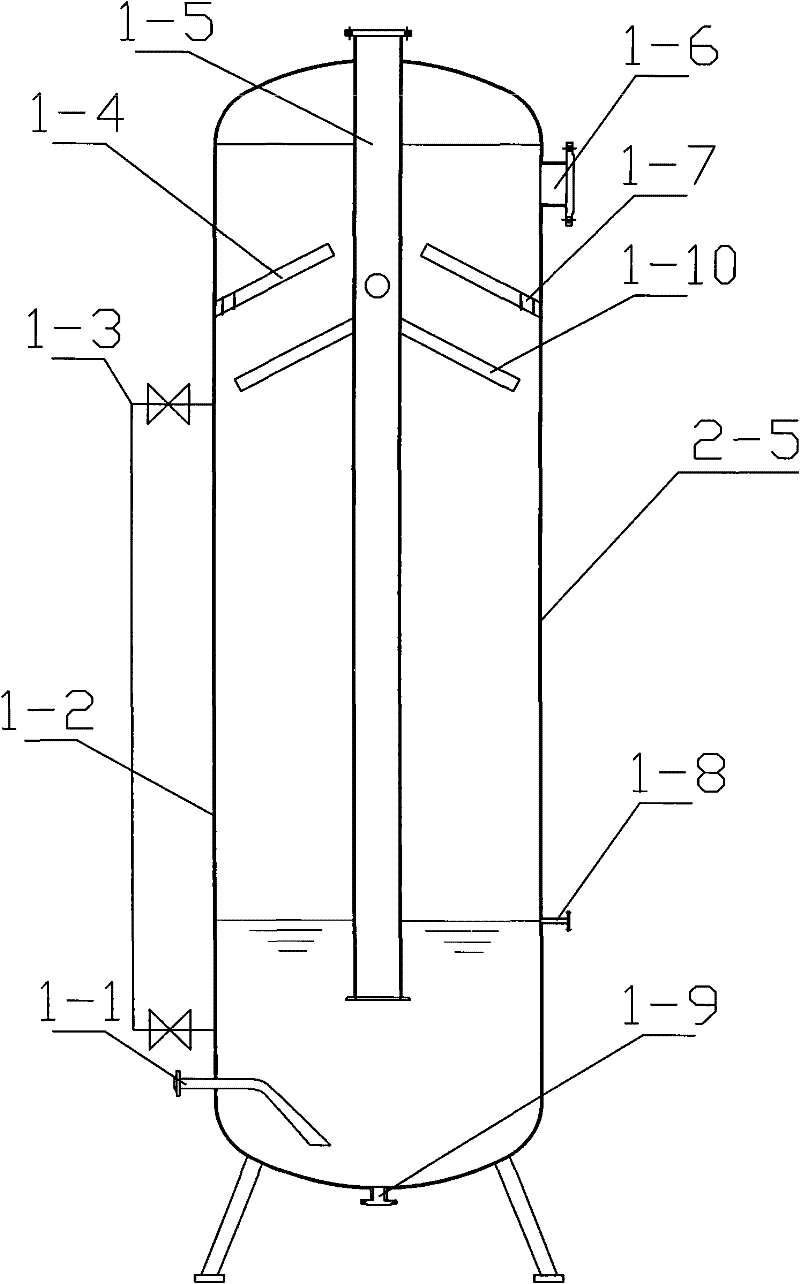

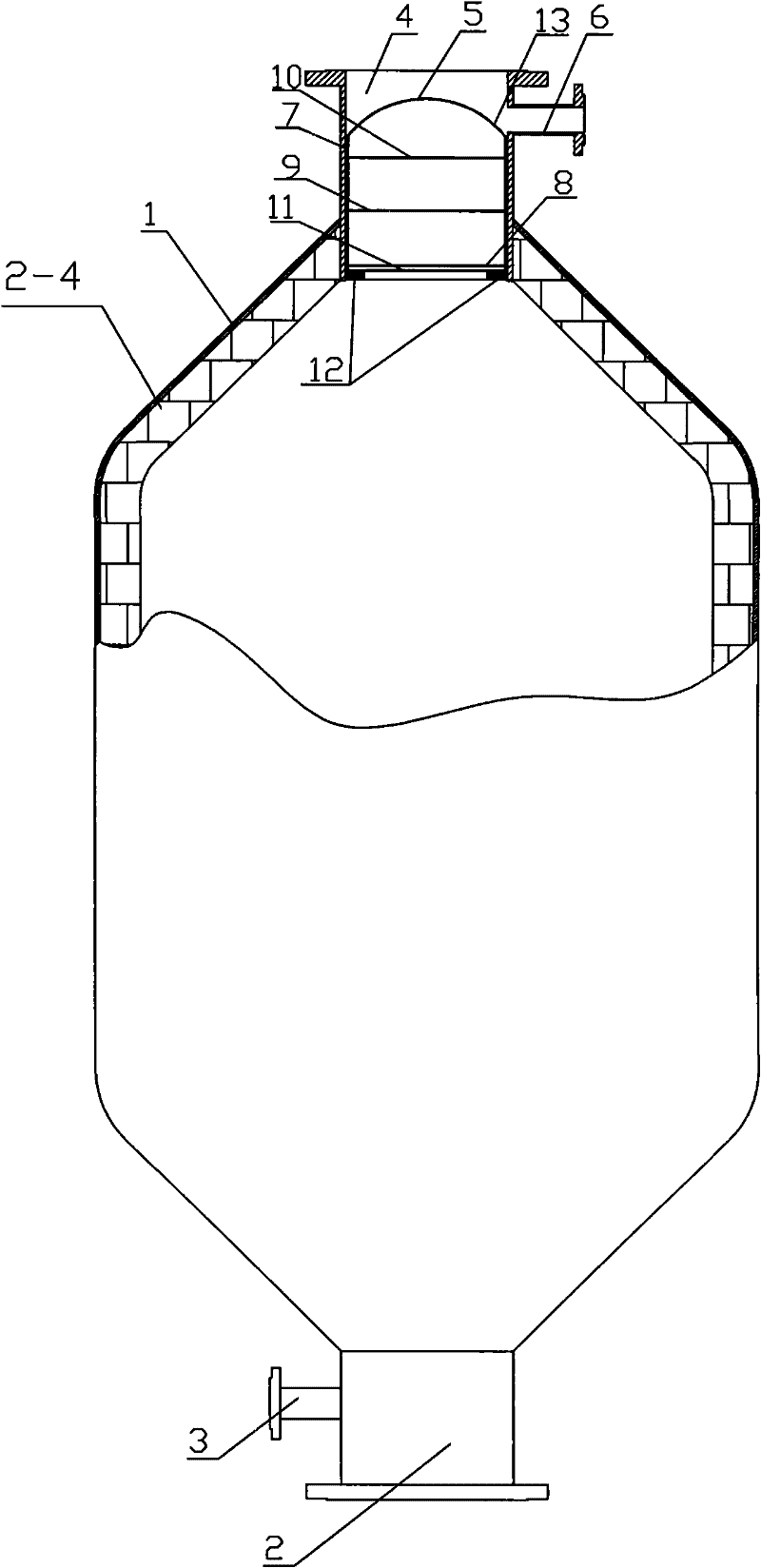

[0027] A special equipment for furfural production, such as figure 1 As shown, it includes pulverizer 2-1, acid mixing machine 2-2, feeder 2-3, hydrolysis kettle 2-4, primary distillation tower 2-6, rectification tower 2-7 and boiler 2-8, boiler 2 -8, hydrolysis kettle 2-4, washing tank 2-5, initial distillation tower 2-6 and rectification tower 2-7 are connected successively, and hydrolysis kettle 2-4 is four hydrolysis kettles connected in series, and the outlet of the previous hydrolysis kettle The air pipe is connected in series with the intake pipe of the next hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com