Filtering and impurity removing technology for oil with high colloid content

A technology for filtering and removing impurities and colloidal content is applied in the field of food oil refining, which can solve the problems of poor filtering and removing effects, unfavorable economic benefits, and high production costs, and achieve the effects of reduced procedures, high comprehensive benefits, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

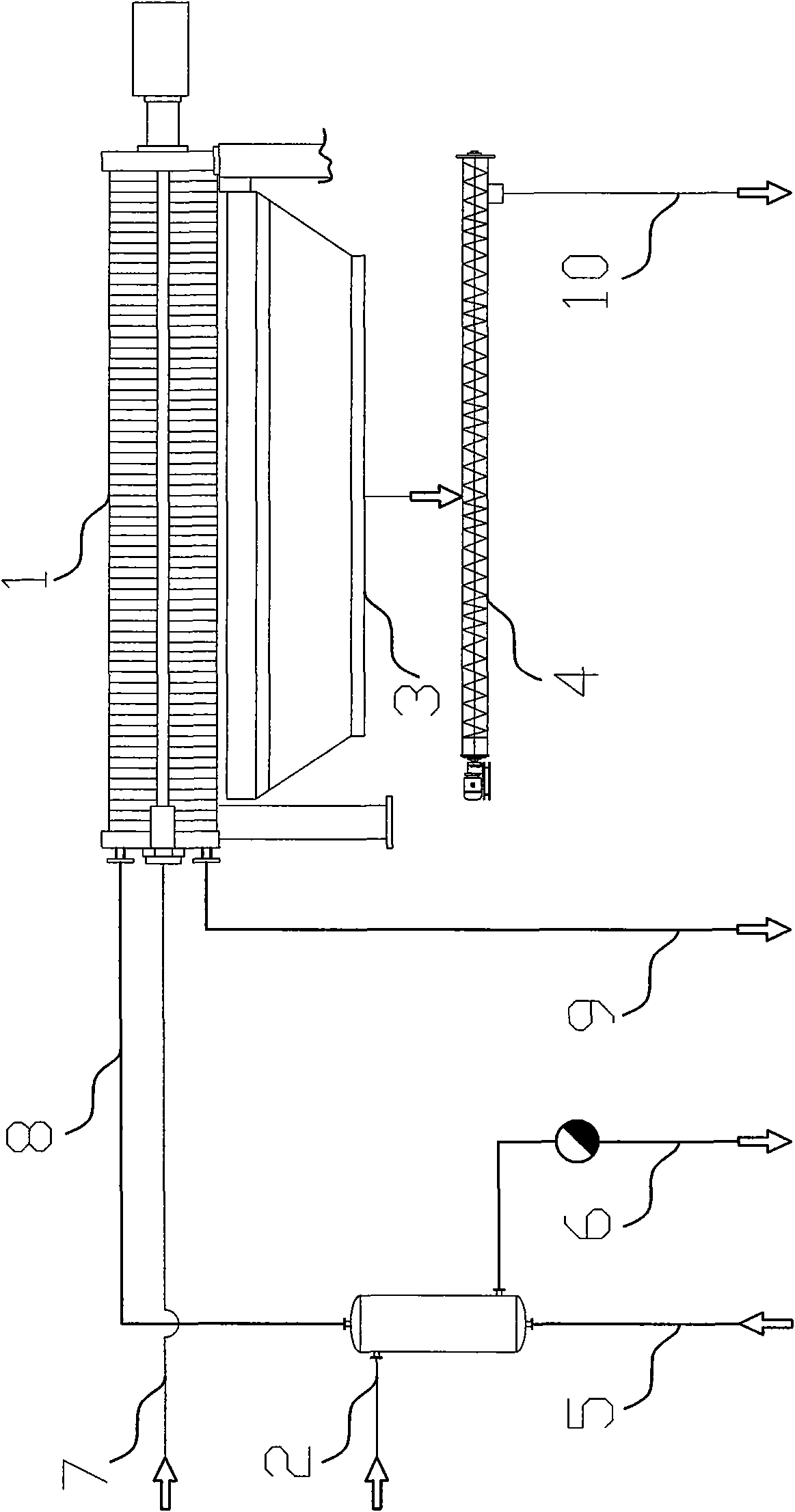

[0008] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as shown in Figure 1, the technological process of the present invention is that vegetable oil crude oil enters raw material oil heater 2 heating from oil supply pipeline 5, after being heated to 40-50 ℃, is transported by oil pipeline 8 Enter the program-controlled membrane filter press 1, the filtered clean oil flows out through the oil pipeline 9, and the filtered residue cake is blown by the compressed air input from the pipeline 7 and squeezed dry from the tympanic membrane, and then falls off the filter cloth, and is removed by the opened filter plate. The gap falls into the slag cake collection tank 3, and then it is conveyed by the slag cake conveying auger 4 integrated with it, and is packed and loaded through the discharge port 10.

[0009] The program-controlled membrane filter press 1 is an existing product, which is generally used in the fields of starch process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com