Active lime powder surface modifier and production method thereof

A technology of active lime and improver, which is applied in the field of surface improver of active lime powder, can solve the problems of high raw material requirements for modifier, insufficient fluidity, weak moisture resistance of lime powder, etc., and achieve strong waterproof performance and high The effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

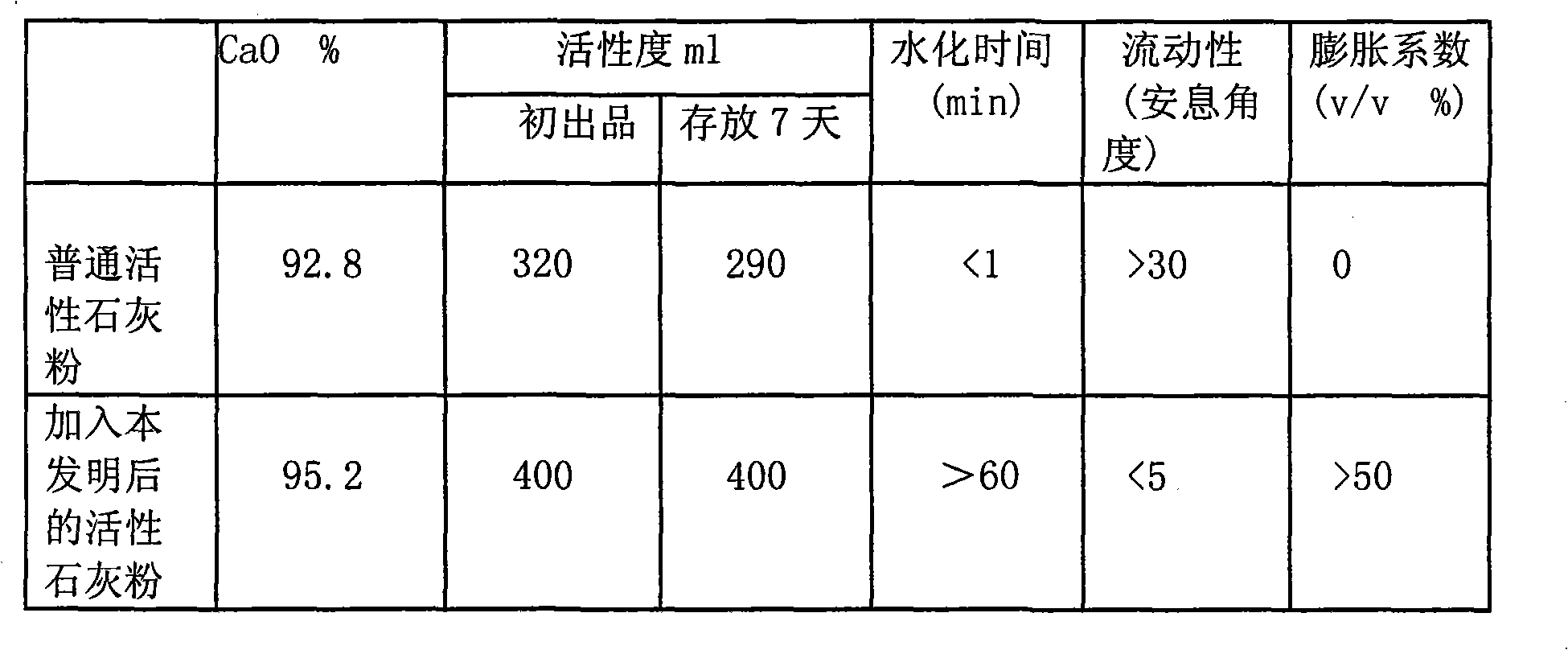

Image

Examples

Embodiment 1

[0027] An active lime powder surface improver, its composition and weight ratio are: chromium trichloride 40, 95% ethanol solution 92, soap powder 20, 40% potassium hydroxide solution 5.2, calcium oxide 100, organic silicon oil 7.1.

[0028] A production method of the above-mentioned quicklime powder surface improver: after the above-mentioned components are prepared according to the stated ratio, firstly mix and stir the chromium trichloride, ethanol solution and soap powder, then heat to 75°C and keep the temperature for 2 hours, Then add potassium hydroxide solution and react for 1.5 hours, then add calcium oxide and organic silicon oil in sequence, mix and stir, and finally cool down in the daily environment to obtain the finished product.

Embodiment 2

[0030] An active lime powder surface improver, its composition and weight ratio are: chromium trichloride 60, 96% ethanol solution 110, soap powder 30, 30% potassium hydroxide solution 6, calcium oxide 100, organic silicon oil 11.

[0031] A production method of the above-mentioned active lime powder surface improver: after the above-mentioned components are prepared according to the ratio, firstly mix and stir the chromium trichloride, ethanol solution and soap powder, then heat to 79°C and keep it warm for 2 hours , and then add potassium hydroxide solution to react for 1.5 hours, then add calcium oxide and organic silicon oil in turn, mix and stir, and finally cool down in the daily environment to obtain the finished product.

Embodiment 3

[0033] An active lime powder surface improver, its composition and weight ratio are: chromium trioxide 53, 99% ethanol solution 99, soap powder 24, 50% potassium hydroxide solution 5.7, polyethylene paraffin 100, organic silicone oil 9.

[0034] A production method of the above-mentioned active lime powder surface improver: after the above-mentioned components are prepared according to the ratio, firstly mix and stir the chromium trioxide, ethanol solution and soap powder, then heat to 75°C and keep it warm for 2 hours, Then add potassium hydroxide solution and react for 1.5 hours, then add polyethylene paraffin and organic silicon oil in turn, mix and stir, and finally cool down in the daily environment to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com