Method for preventing circularity over tolerance of large gear ring after heat treatment

A ring gear and large-scale technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as increased procedures, construction period, energy consumption and labor intensity, complex processing procedures of large ring gears, excessive deformation of parts, etc. Achieve the effects of avoiding waste products, shortening the manufacturing cycle, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

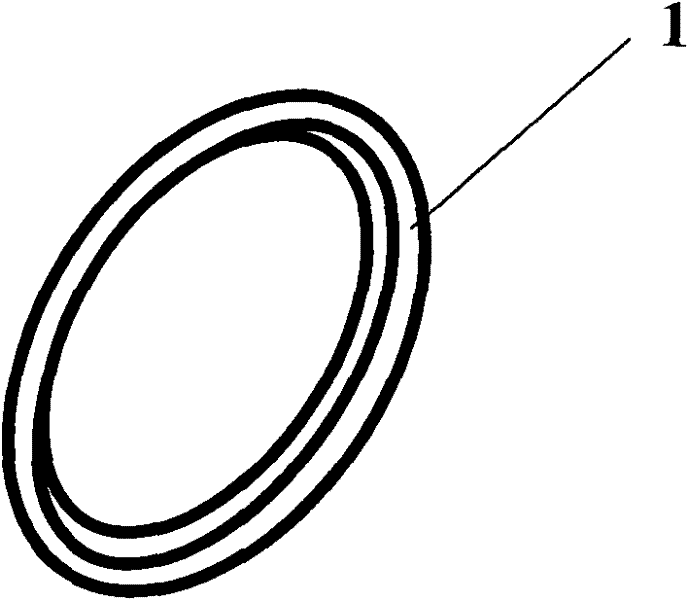

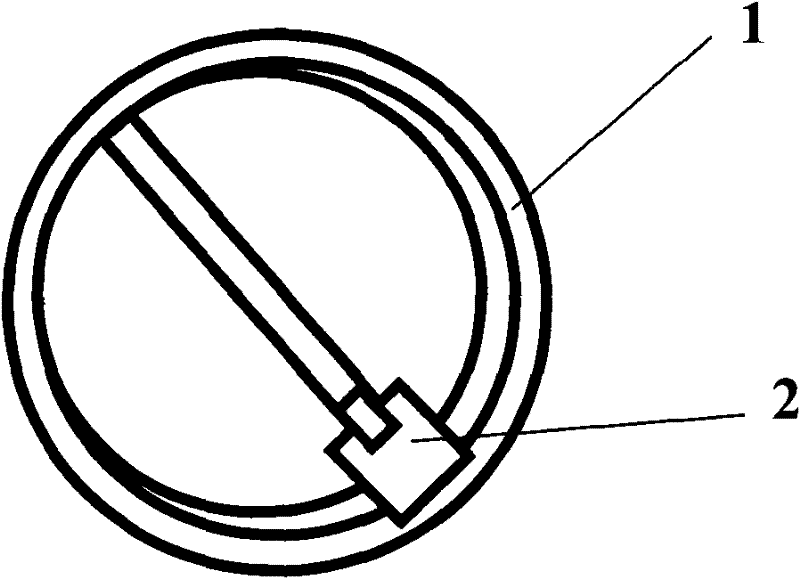

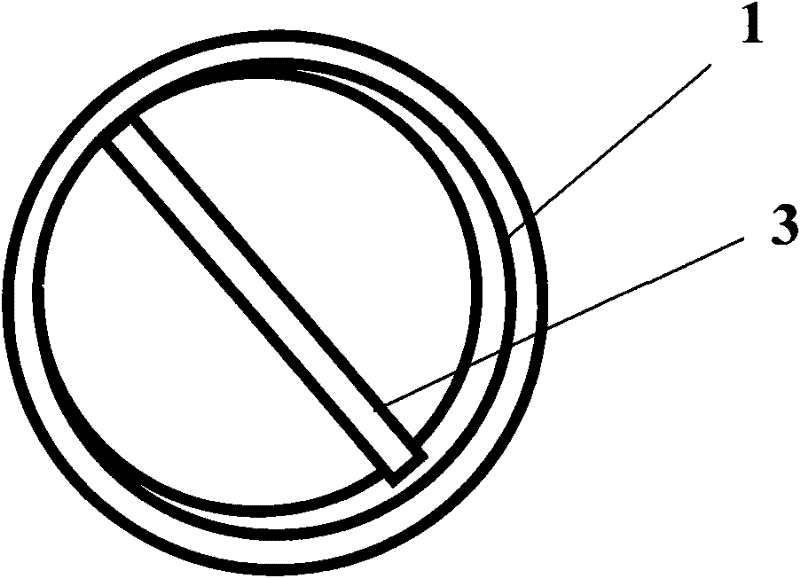

[0027] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a method to prevent the roundness of the large ring gear from being out of tolerance after heat treatment includes the following steps:

[0028] A. Pre-select the easily deformable large ring gear 1;

[0029] B. Perform quenching and tempering treatment on the large ring gear 1, that is, quenching + high temperature tempering, and control the final cooling temperature between the Ms point and the Mz point of the material after quenching;

[0030] C. Deformation measurement of the large ring gear 1;

[0031] D. Put the large ring gear 1 with elliptical deformation at 1 / 4 of the height of the large ring gear 1 in the short axis direction of the large ring gear 1 with a jack 2 until the large ring gear 1 with elliptical deformation reaches the required size;

[0032] E. Place the pre-prepared jacking shaft 3 at 3 / 4 of the height of the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com