Method for preparing hydrophobic aerogel and hydrophobic aerogel prepared therefrom

An airgel and hydrophobic technology, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve problems such as low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

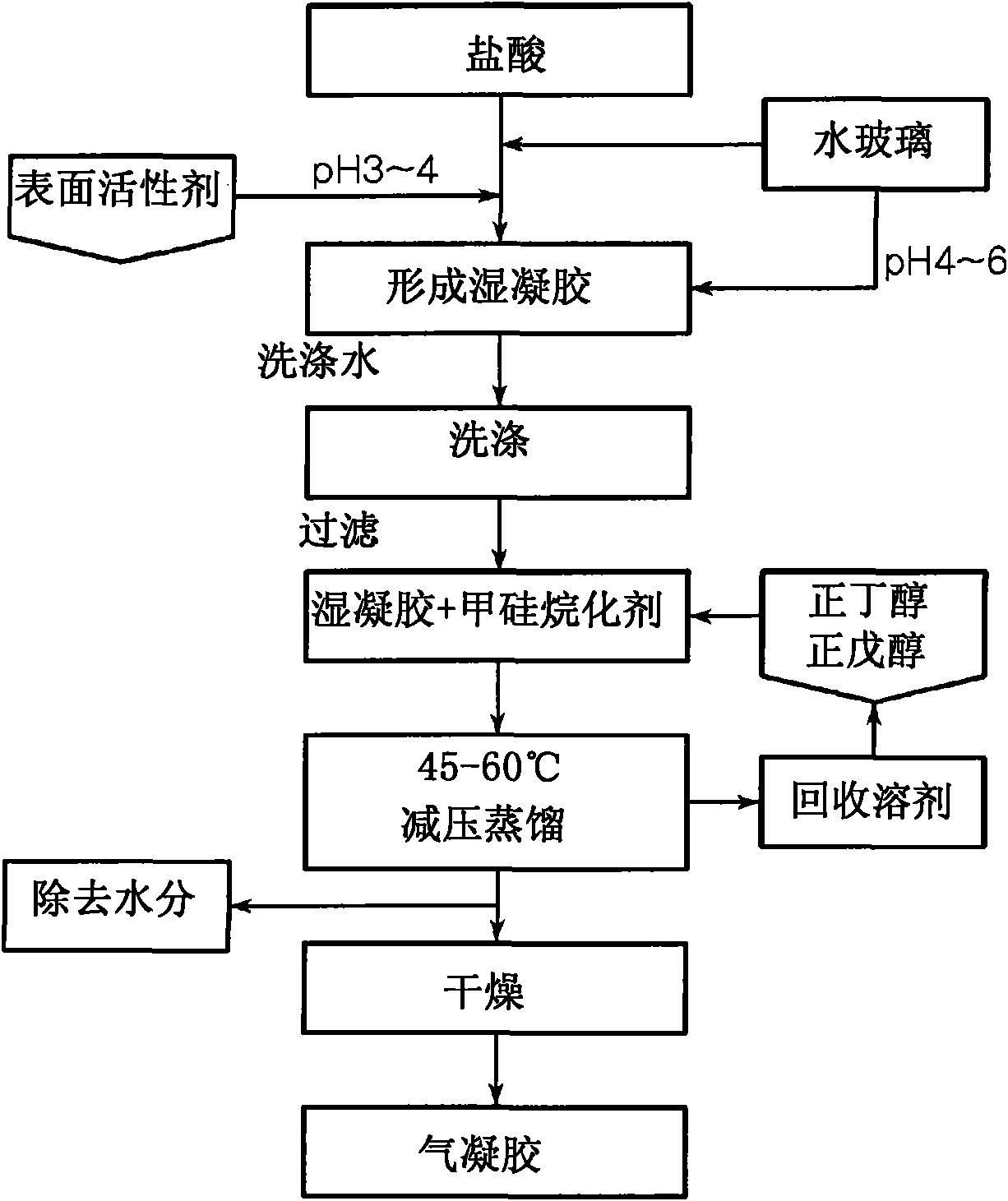

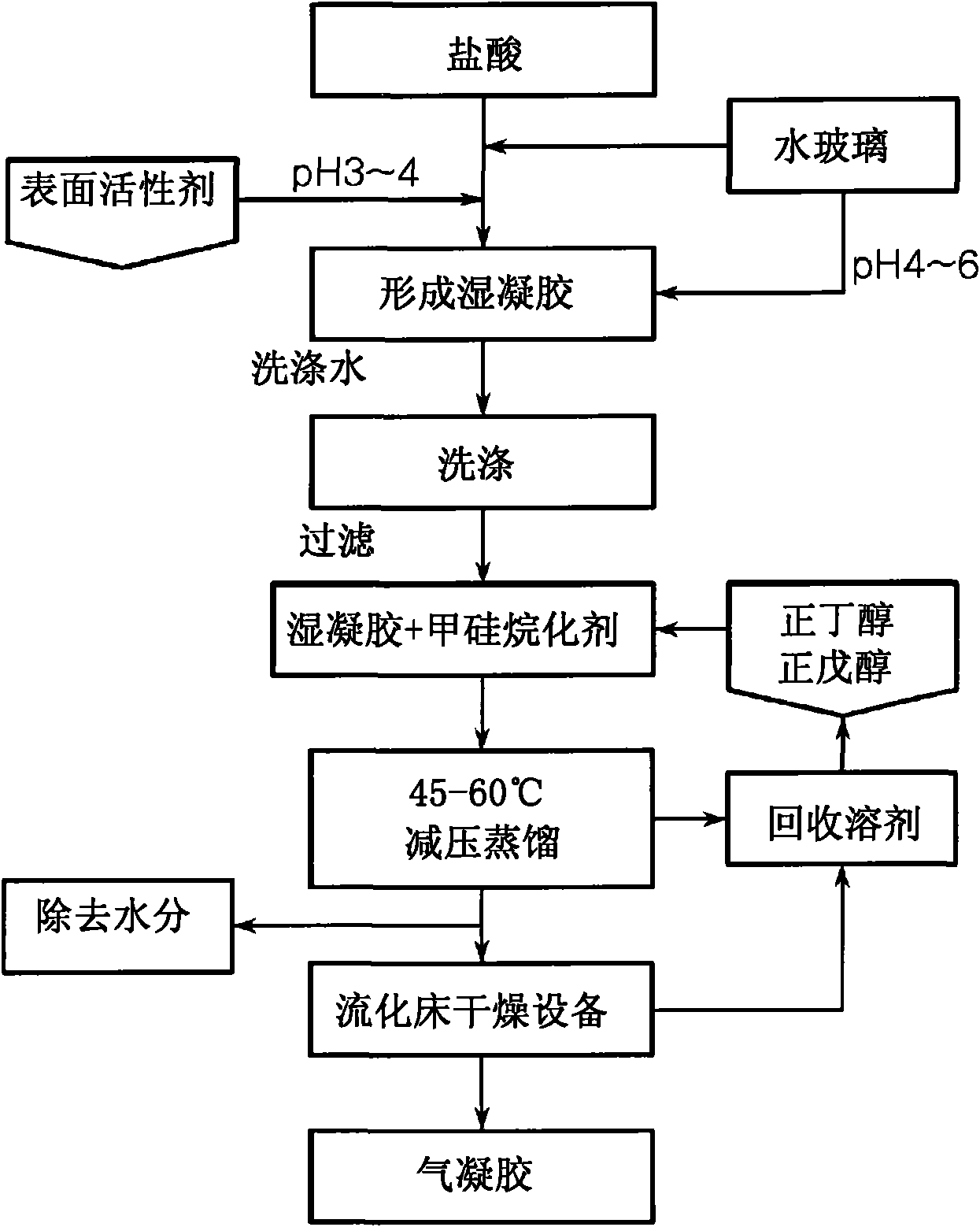

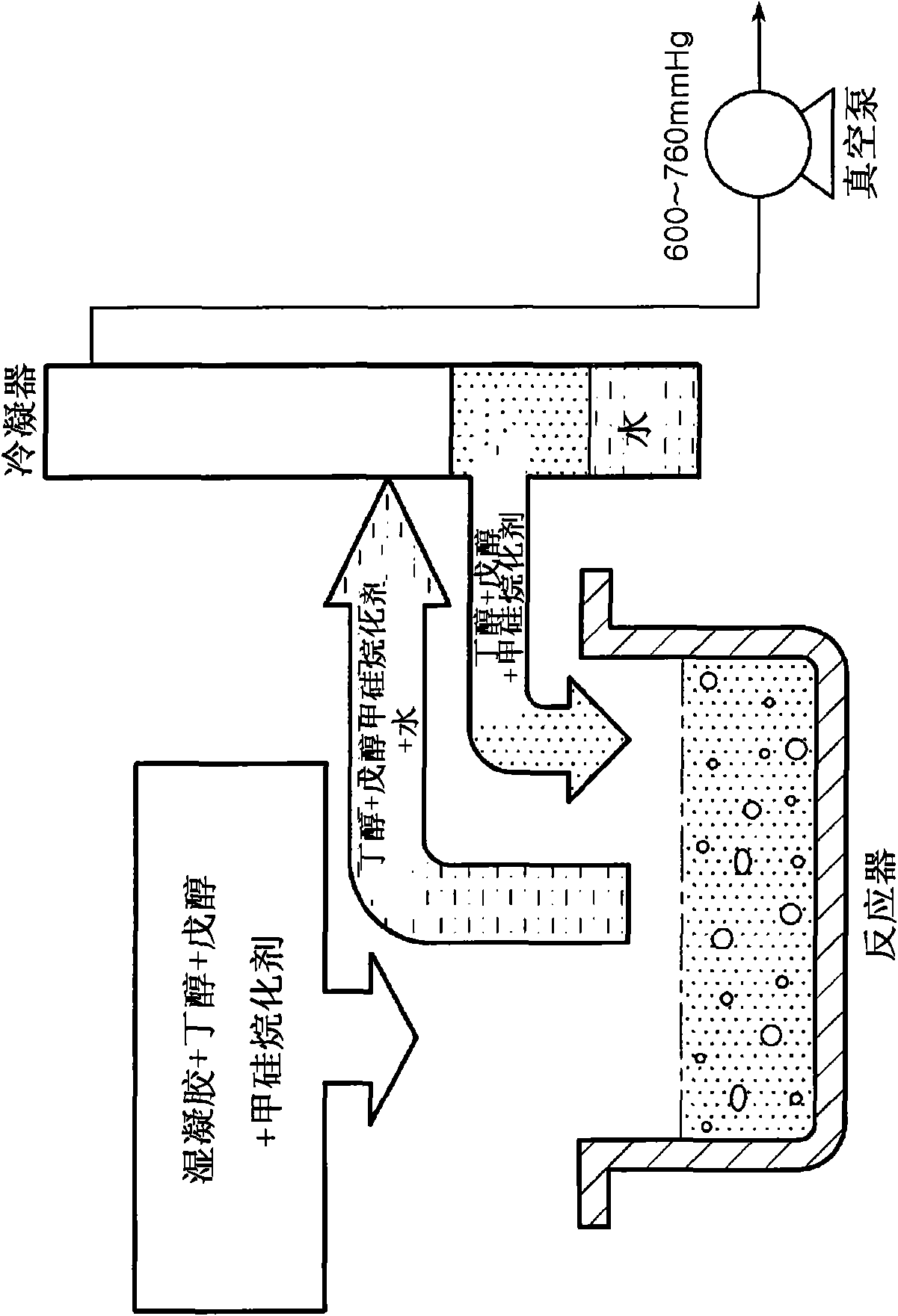

[0034] The present invention relates to a new method for preparing hydrophobic aerogels, which can prepare wet gels from water glass using surfactants, and the wet gels have a higher specific surface area than wet gels prepared according to conventional methods. The silylation agent and solvent are recovered by a one-step process under reduced pressure in the reactor within 60 minutes of processing time. This one-step process includes: very fast separation and removal of water from the silica wet gel ; Hydrophobic treatment on the surface of the silica gel, which can impart permanent hydrophobicity to the silica gel; and reuse the remaining silylation agent and solvent.

[0035] In addition, the method of the present invention is characterized in that by using a mixed solution of n-pentanol and n-butanol as a solvent, the recovery rate of the solvent and the expensive silylation agent can be increased, and the purity of the recovered solvent can be improved.

[0036] According to t...

Embodiment 1

[0048] At room temperature, while stirring, add a water glass solution (a solution obtained by diluting a 35wt% (wt%) sodium silicate solution 3 times with water) to a 5L (liter) 1N hydrochloric acid solution, until the pH of the resulting solution is adjusted to pH 3.5. After stirring for 1 hour, 3 wt% (percent) polyethylene glycol based on the total weight of the silica powder particles finally prepared was added to the water glass solution, and water glass was added to slowly increase the pH of the resulting solution to pH 5. When the water glass solution was stirred for about 2 hours, the gel began to appear. The wet gel prepared in this way is washed several times with a sufficient amount of distilled water to remove Na ions, Cl ions and remaining surfactants present in the inside of the wet gel, and dehydrated by sufficient filtration. Then, 300 mL (ml) n-pentanol and 2500 mL (ml) n-butanol were mixed, and 5% by weight (percent) of hexamethyldisiloxane (HMDSO) based on ...

Embodiment 2

[0058] At room temperature, a water glass solution (a solution obtained by diluting a 35% by weight (percent) sodium silicate solution with water) was added to 5L of 1N hydrochloric acid solution while stirring, until the pH of the resulting solution was adjusted to pH 3.5. After stirring for 1 hour, 3% by weight (percent) of polyethylene glycol based on the total weight of the final prepared silica powder particles was added to the water glass solution, and the pH of the resulting solution was slowly increased by adding water glass To pH 5. When the water glass solution was stirred for about 2 hours, the gel began to appear. The wet gel prepared in this way is washed several times with a sufficient amount of distilled water to remove Na ions, Cl ions and remaining surfactants present in the inside of the wet gel, and dehydrated by sufficient filtration. Then, 400 mL (milliliter) of n-pentanol and 2500 mL (milliliter) of n-butanol were mixed, and 5% by weight (percent) of hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com