Preparation method of high effective retention and filtration agent cationic guar gum

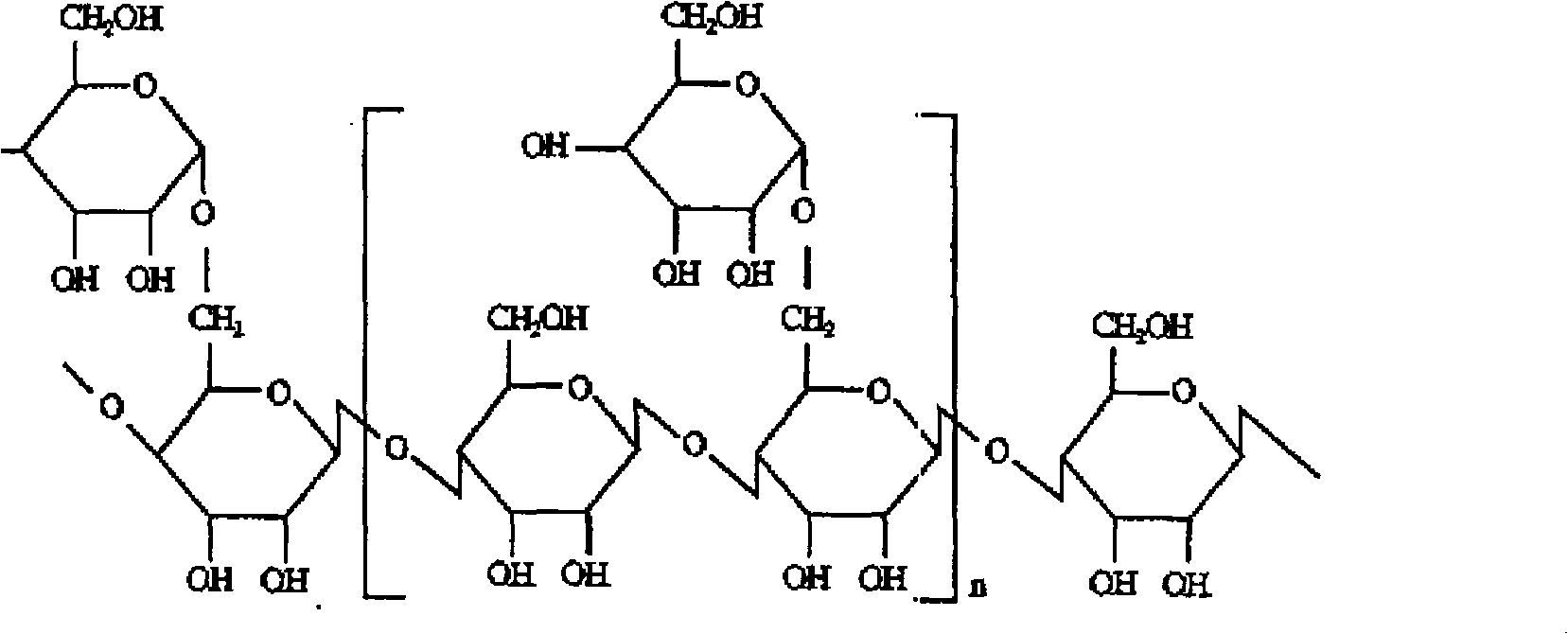

A technology of cationic guar gum and retention and drainage aids, applied in the field of analytical biology, can solve the problems of insignificant retention and drainage effects, large usage, low substitution degree, etc., achieve good retention and drainage effects, improve The effect of mild retention and etherification reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

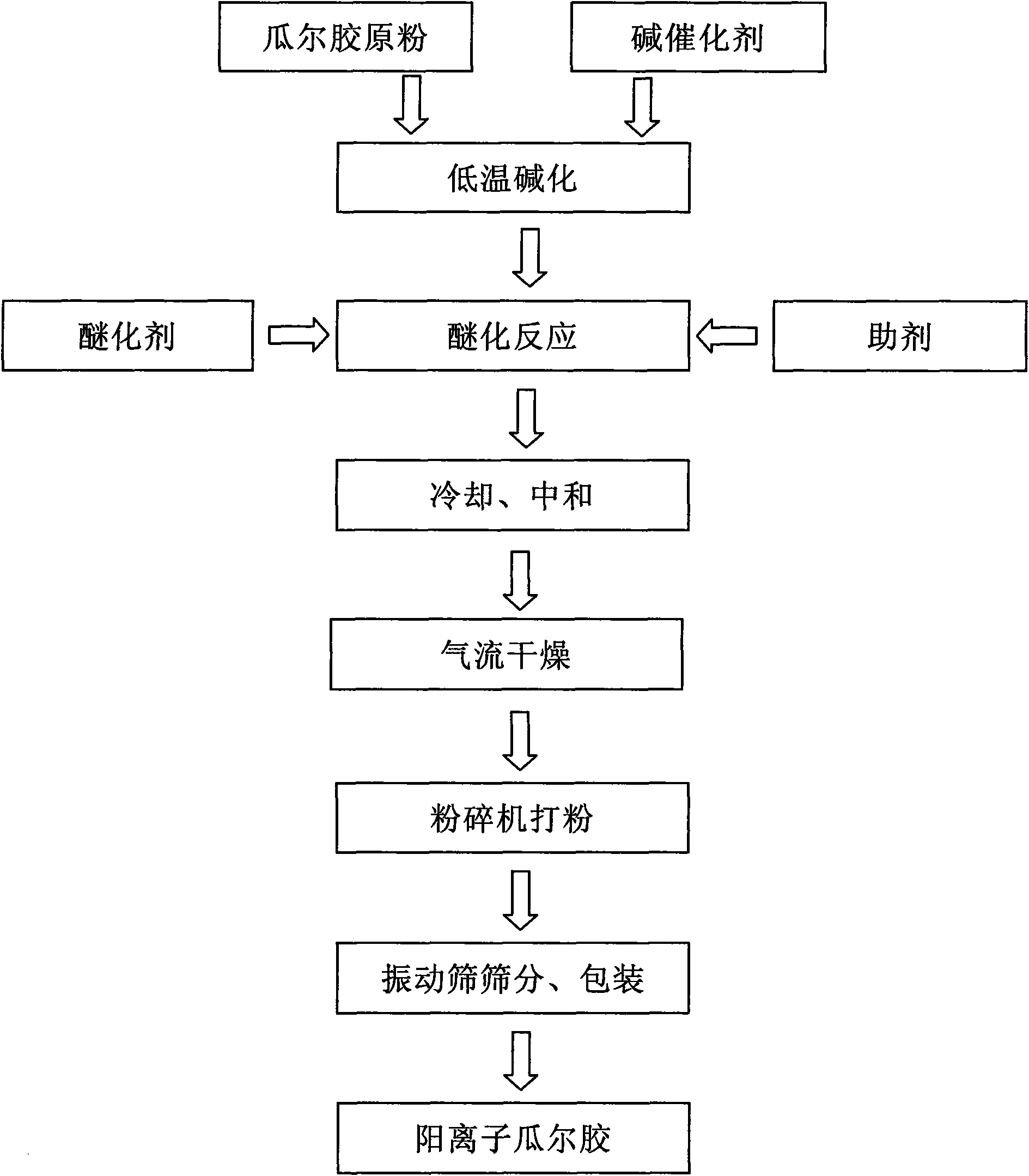

[0021] The preparation method of the cationic guar gum of the high-efficiency retention and drainage aid of the present invention adopts the following process steps:

[0022] 0.5Kg of potassium hydroxide is added to 100Kg of guar collagen powder and prepared into a solution during use with a mass concentration of 10%-60%. Alkalinize at 20°C for 30 minutes, then add 10Kg of cationic etherification agent 3-chloro-2-hydroxypropyl dodecyl dimethyl ammonium chloride, raise the temperature to 60°C, add potassium chloride at 0.5Kg React for 1h under the action of the reaction, cool down after the reaction, and neutralize with dilute hydrochloric acid with a mass concentration of 10%. The crude product after neutralization enters the airflow dryer and is dried at 105°C for 5min. The dry material after drying contains water The rate is 10%. After drying and dehumidifying, the intermediate product has a fineness of 100 mesh after being pulverized by a pulverizer, and is sieved by a vibr...

Embodiment 2

[0024] The preparation method of the cationic guar gum of the high-efficiency retention and drainage aid of the present invention adopts the following process steps:

[0025] Add 1Kg of sodium hydroxide to 100Kg of guar collagen powder, and prepare a solution during use, with a mass concentration of 10%-60%. Alkaline at 30°C for 10 minutes, then add 20Kg of cationic etherification agent 2,3-epoxypropyltrimethylammonium chloride, heat up to 65°C, and react for 1.5h under the action of 4Kg of auxiliary agent sodium chloride , cool after the reaction, and neutralize with 50% acetic acid. The neutralized crude product enters the airflow dryer and is dried at 130°C for 2 minutes. The moisture content of the dry material after drying is 8%. After drying The intermediate product after dehumidification is pulverized by a pulverizer and the fineness reaches 100 mesh, and is sieved by a vibrating sieve to obtain an efficient retention and drainage aid cationic guar gum.

Embodiment 3

[0027] The preparation method of the cationic guar gum of the high-efficiency retention and drainage aid of the present invention adopts the following process steps:

[0028] Add 4Kg of sodium hydroxide to 100Kg of guar collagen powder, and prepare a solution during use with a mass concentration of 10%-60%. Alkaline at 40°C for 60 minutes, then add 30Kg of cationic etherification agent 3-chloro-2-hydroxypropyltrimethylammonium chloride, heat up to 80°C, and react for 4 hours under the action of 6Kg of auxiliary agent potassium chloride , cool after the reaction, and neutralize with 30% acetic acid. The neutralized crude product enters the airflow dryer and is dried at 115°C for 10 minutes. The moisture content of the dry material after drying is 10%. After drying The intermediate product after dehumidification is pulverized by a pulverizer and the fineness reaches 100 mesh, and is sieved by a vibrating sieve to obtain an efficient retention and drainage aid cationic guar gum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com