Magnetic field deironing and purifying device of condensed water

A purification device and magnetic field technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Time to replace or build membrane, promote water purification technology, speed up the effect of the start-up process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

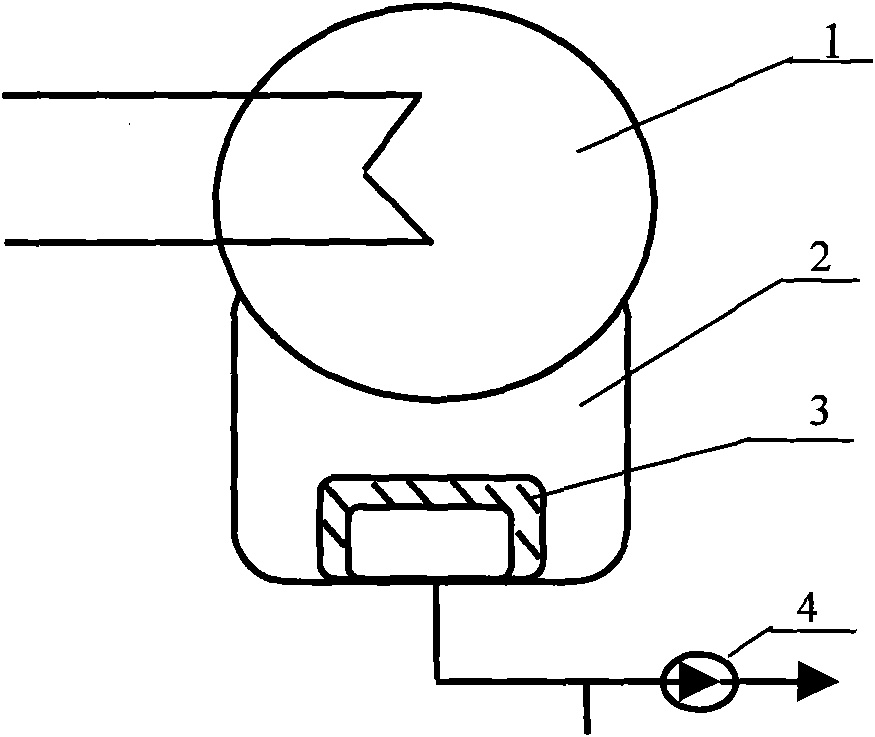

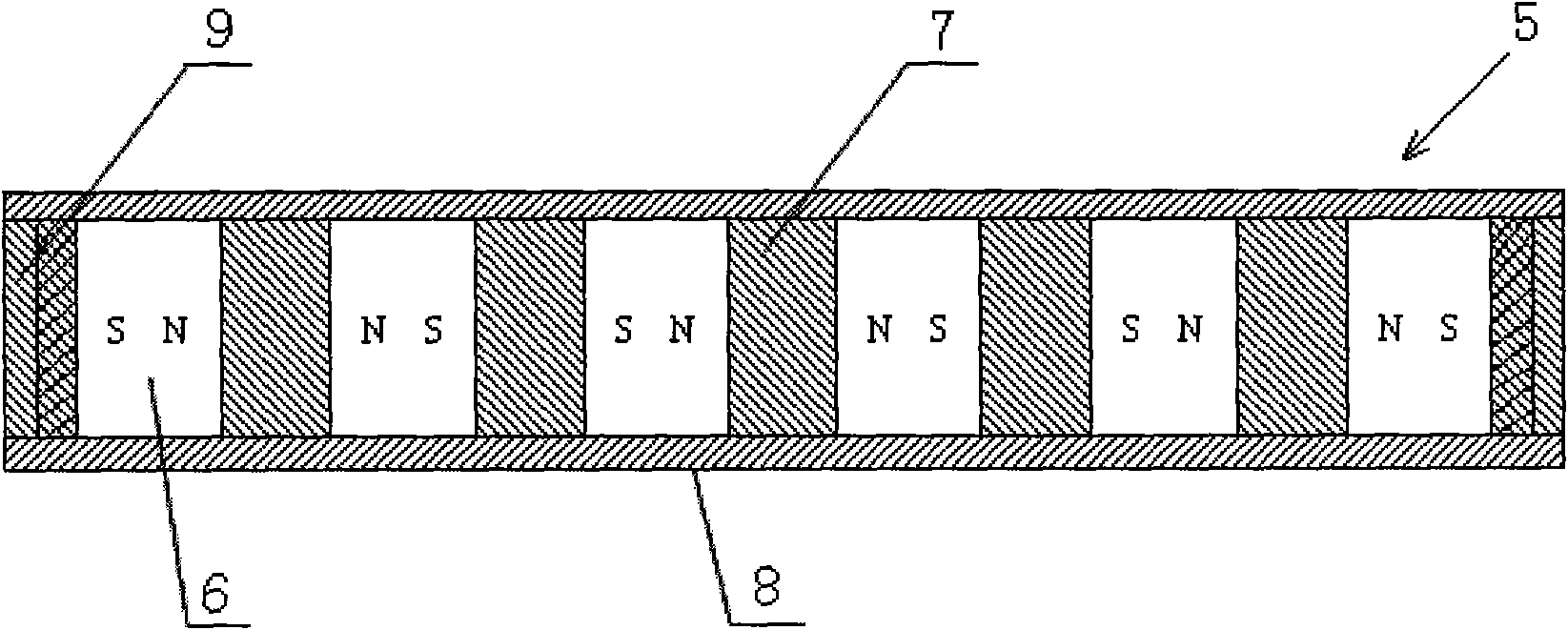

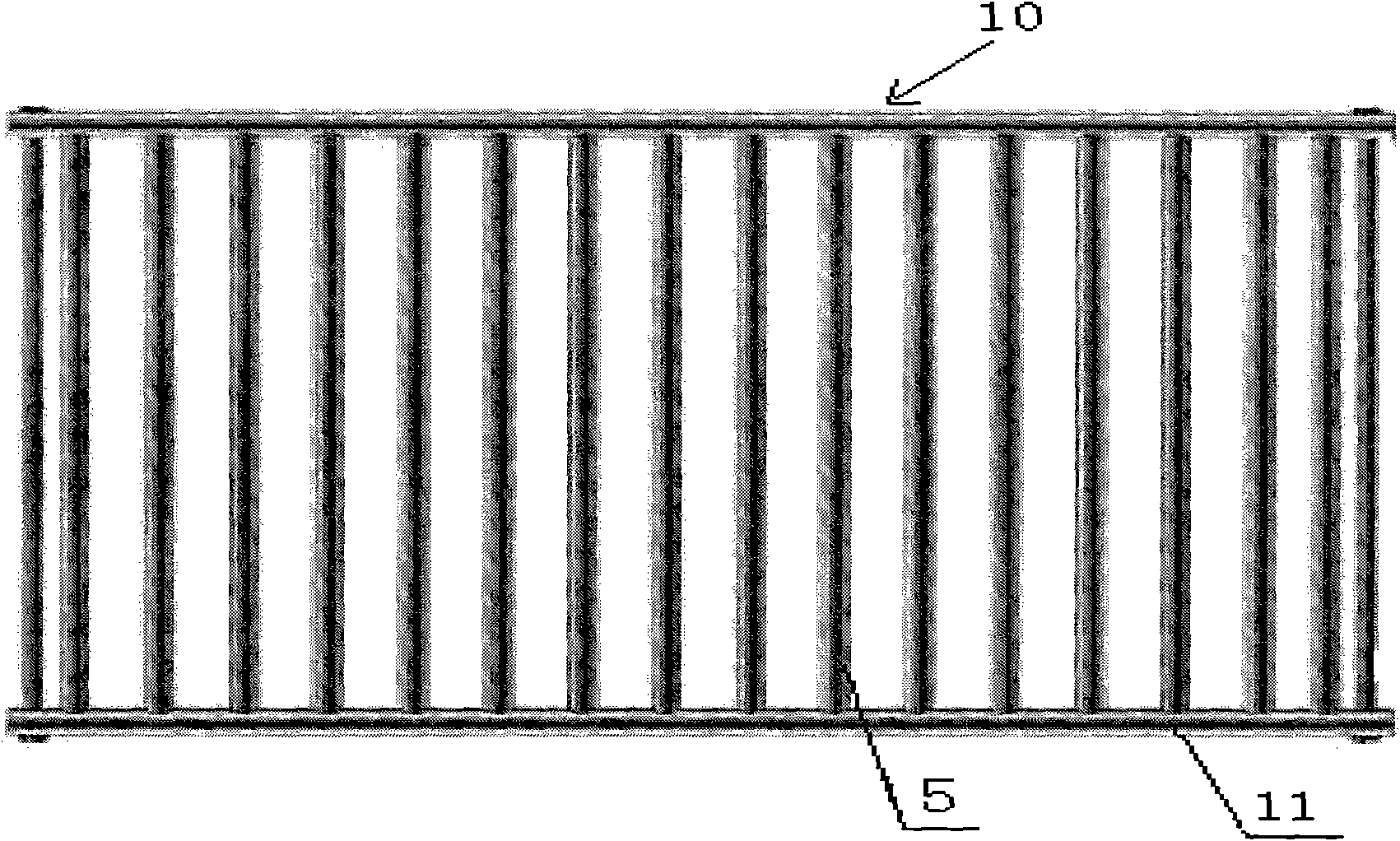

[0023] see figure 1 , the present invention is a condensed water magnetic field iron removal and purification device 3 directly installed in the hot water well of the steam turbine condenser. Iron removal and purification of water. see figure 2 , the magnetic unit assembly is a permanent magnet tube 5, and in the permanent magnet tube 5, several permanent magnets 6 are fixedly packaged in the form of facing each other with the same poles. The guide filling pieces 7 are arranged between the permanent magnets 6, the outer shell of the permanent magnet tube 5 is a stainless steel outer sleeve 8, and the inside of the two ends of the outer sleeve 8 is filled with a non-magnetic material, and the outermost end is sealed by a mechanical seal head 9. Plugging or sealing for argon arc welding. The structural characteristics of the permanent magnet tube are fully considered to expand the working surface area of the permanent magnet tube as much as possible. Therefore, when the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com