Polyvinylidene chloride (PVDC) copolymer latex for medicine packaging as well as preparation method and application thereof

A technology for vinylidene chloride and packaging, which is applied in the field of polyvinylidene chloride copolymer latex for water-based pharmaceutical packaging and its preparation. It can solve the problems of high barrier property and no crystal point, and achieve high barrier property and low latex viscosity. , good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

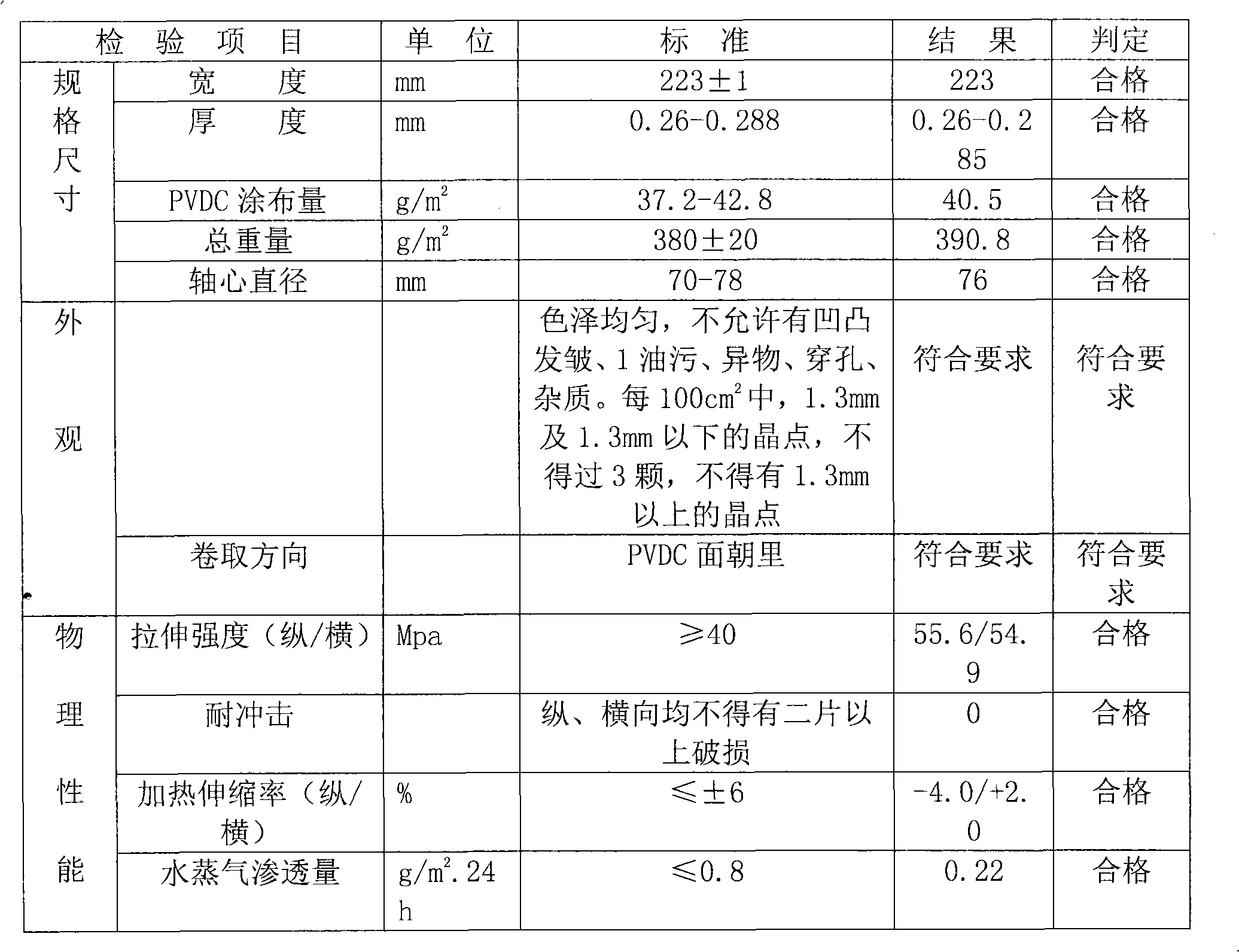

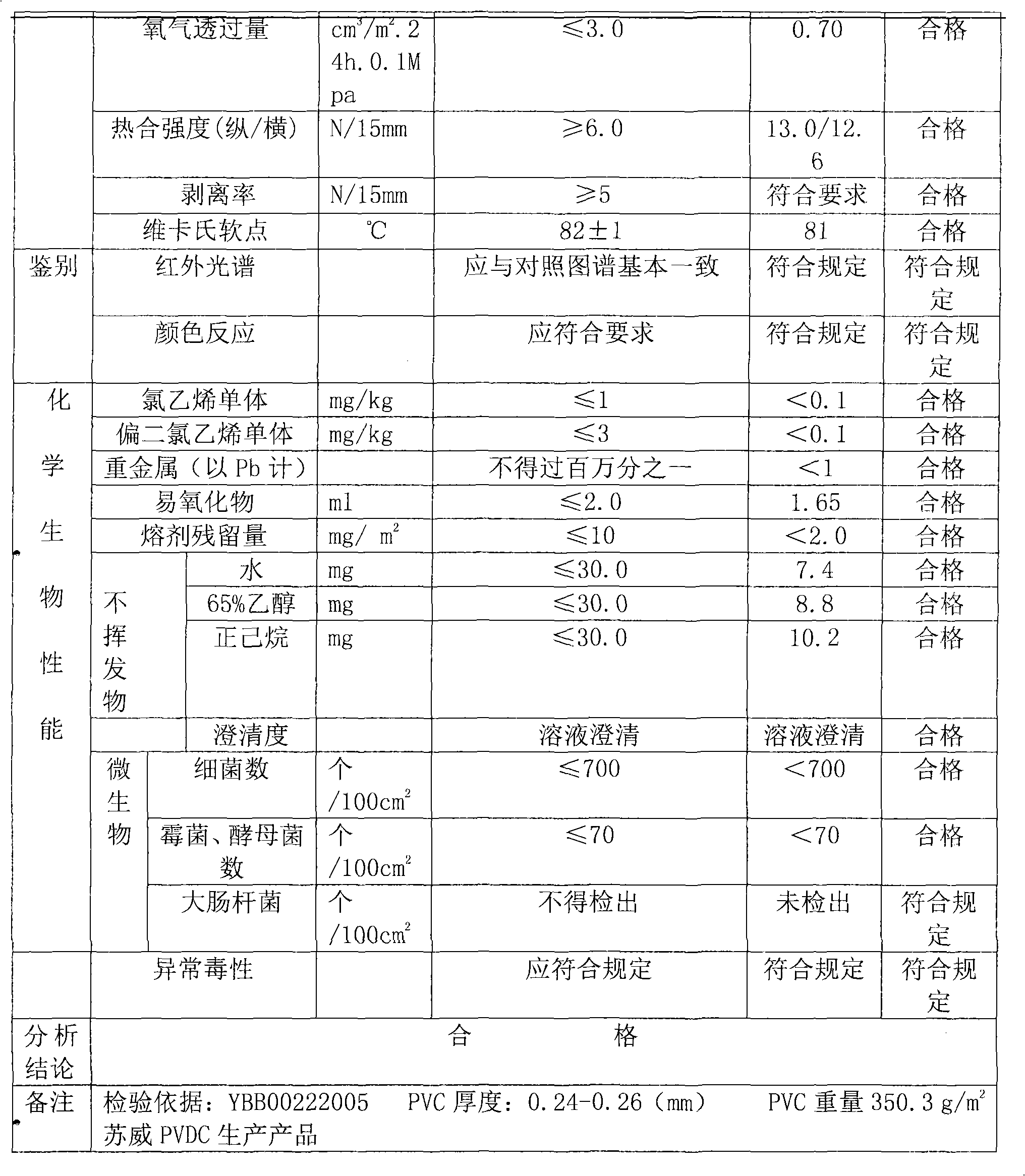

Image

Examples

Embodiment 1

[0025] (1) Kettle material:

[0026] Deionized water 40Kg Sodium dodecyl sulfate 0.7Kg

[0027] Glacial acetic acid 0.01Kg Nano SiO 2 5g

[0028] Tert-butyl hydroperoxide 2g ferrous chloride 5g;

[0029] (2) Mixed monomers:

[0030] Vinylidene chloride 51Kg Acrylonitrile 3Kg

[0031] n-butyl acrylate 4Kg methacrylic acid 2Kg;

[0032] (3) Initiator:

[0033] Initiator A: tert-butyl hydroperoxide 0.08Kg

[0034] Deionized water 10Kg

[0035] Initiator B: carved white powder 0.1Kg

[0036] Deionized water 10Kg.

[0037] (4) Specific operation process:

[0038] ①Add 40Kg of deionized water, 0.7Kg of sodium dodecylsulfonate, 0.01Kg of glacial acetic acid, 0.005Kg of ferrous chloride, and nano-SiO into the reaction kettle. 2 0.005Kg, tert-butyl hydroperoxide 0.002Kg, vacuumize in the reactor, replace with nitrogen, then vacuumize, replace with nitrogen, and then vacuumize;

[0039] ②Based on the weight of 100 parts of the mixed monomer, add 20 parts of the mixed monomer...

Embodiment 2

[0049] Still material, initiator is identical with embodiment 1, and difference is that the composition of mixed list is:

[0050] Vinylidene chloride 50Kg Acrylonitrile 3Kg

[0051] 6Kg of n-butyl acrylate and 3Kg of acrylic acid.

[0052] The preparation method of embodiment 2 is as embodiment 1.

Embodiment 3

[0054] Still material, initiator is identical with embodiment 1, and difference is that the composition of mixed list is:

[0055] Vinylidene chloride 60Kg Acrylonitrile 2Kg

[0056] 6Kg of n-butyl acrylate and 1Kg of acrylic acid.

[0057] The preparation method of embodiment 2 is as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com