Gas-reducing inhibitor of methyl gasoline

A methanol gasoline and degassing technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of insufficient use effect, and achieve the effects of good effect, increased process and cost, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

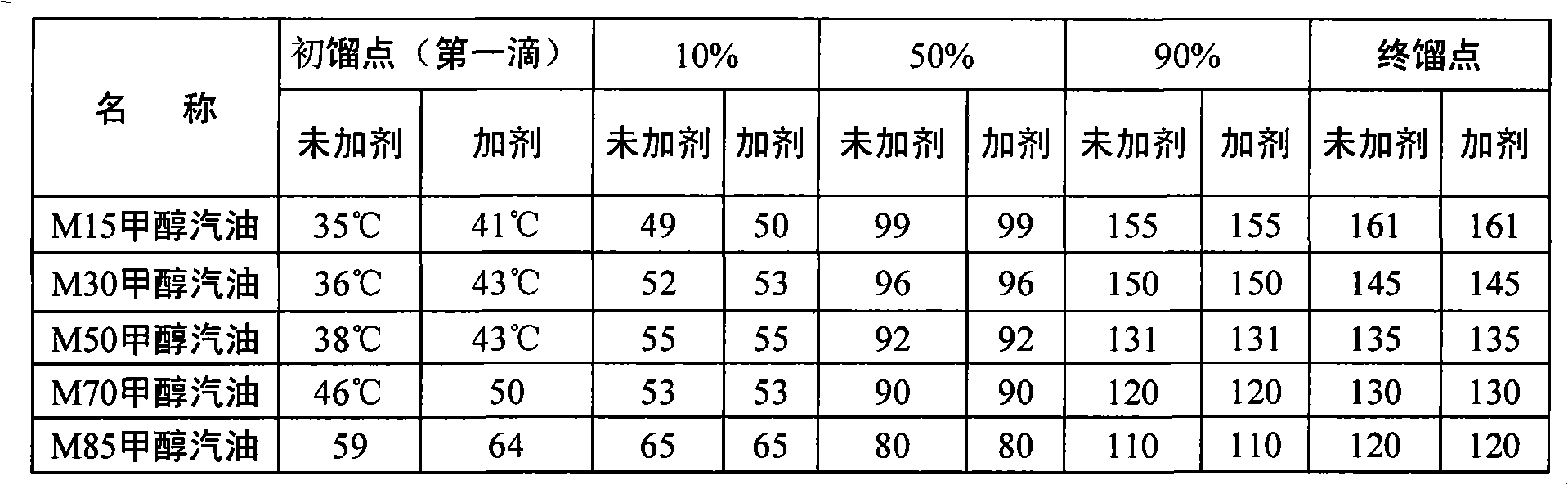

Image

Examples

Embodiment 1

[0018] A kind of methanol gasoline vapor drag reducing agent, its component and weight percent are as follows:

[0019] Fatty Ketones 80%

[0020] Morpholines 12%

[0021] Fatty aldehyde 5%

[0022] Fatty ether 3%

[0023] Among them: the aliphatic ketone is methyl tert-butyl ketone; the morpholines are morpholine; the aliphatic aldehyde is isovaleraldehyde; the aliphatic ether is dibutyl ether.

[0024] A vapor drag reducing agent for methanol gasoline, its preparation method is as follows: first add methyl tert-butyl ketone into the blending kettle, add morpholine, isovaleraldehyde, and dibutyl ether respectively while stirring, and mix well to form a transparent liquid That is the finished product of the present invention.

Embodiment 2

[0026] A kind of methanol gasoline vapor drag reducing agent, its component and weight percent are as follows:

[0027] Fatty Ketones 82%

[0028] Morpholines 6%

[0029] Fatty aldehyde 8%

[0030] Fatty ether 4%

[0031] Among them: the aliphatic ketone is dimethyl ethylene diketone; the morpholines are N-methylmorpholine; the aliphatic aldehyde is isobutyraldehyde; the aliphatic ether is diisopropyl ether.

[0032] A methanol-gasoline air drag reducing agent, the preparation method of which is the same as in Example 1.

Embodiment 3

[0034] A kind of methanol gasoline vapor drag reducing agent, its component and weight percent are as follows:

[0035] Fatty Ketones 86%

[0036] Morpholines 4%

[0037] Fatty aldehyde 4%

[0038] Fatty ether 6%

[0039] Among them: aliphatic ketone is trimethylcyclohexanone; morpholine is N-ethyl morpholine; aliphatic aldehyde is octanal; aliphatic ether is diphenyl ether.

[0040] A methanol-gasoline air drag reducing agent, the preparation method of which is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com