Natural plant small molecular group substance concentrate and production method thereof

A technology of natural plants and production methods, which is applied in the field of natural plant small molecule group substance concentrates and their production fields, can solve the problems of high animal disease incidence, lack of active biological small molecules, animal drug-resistant food safety, etc., so as to improve feed nutrition. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

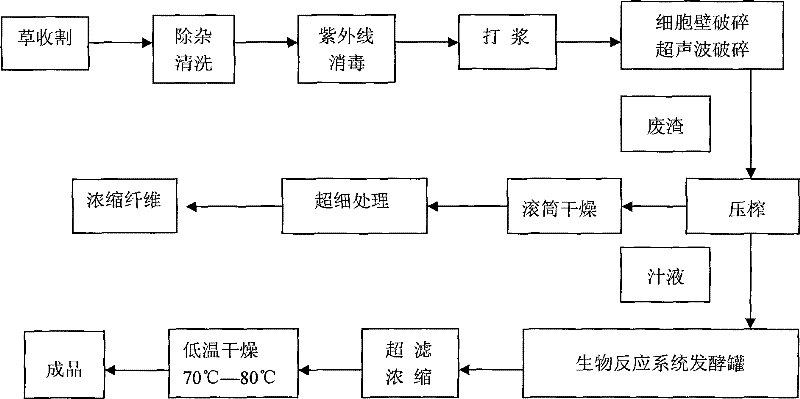

Method used

Image

Examples

Embodiment 1

[0026] The natural plant small molecule group material concentrate is mixed with the plant juice composition of 40% verbena, 30% clover, 10% ryegrass, 10% purple amaranth, and 10% (volume percentage) of pachycarp, and the obtained plant juice After mixing in proportion, place it in a fermenter with a biological reaction system as the fermentation substrate. The fermenter is 5 tons. The plant juice mixed according to the formula ratio is used as the fermentation substrate 4.5 tons, which is 0.2% of the total amount of the fermentation substrate. First add Aspergillus niger strain SICC3.301, that is, the amount of koji added is 9 kg; the temperature is 28°C-30°C, pH 6.5, and fermented for 24 hours; then add Lactobacillus plantarum SICC1 with 0.2% of the total amount of fermentation substrate. 518 kinds of koji, that is, the amount of koji added is 9 kg; the temperature is controlled at 38°C and fermented for 24 hours to obtain the fermentation culture liquid; the obtained ferment...

Embodiment 2

[0028] The natural plant small molecule group material concentrate is mixed with the plant juice composition of verbena 35%, clover 25%, ryegrass 12%, purple amaranth 12%, pachycarp 12% (volume percentage), and the obtained plant juice After mixing in proportion, place it in a fermenter with a biological reaction system as the fermentation substrate. The fermenter is 10 tons, and the plant juice mixed according to the formula ratio is used as the fermentation substrate 9 tons, which is 0.2% of the total amount of the fermentation substrate. First add Aspergillus niger strain SICC3.301, that is, the amount of koji added is 18 kg; temperature is 28°C-30°C, pH 6.5, and fermented for 24 hours; then add Lactobacillus plantarum SICC1 at 0.2% of the total amount of fermentation substrate. 518 kinds of koji, that is, the amount of koji added is 18 kg; the temperature is controlled at 38°C and fermented for 24 hours to obtain the fermentation culture liquid; the obtained fermentation cu...

Embodiment 3

[0030]The natural plant small molecule group substance concentrate is mixed with the plant juice composition of 30% verbena, 20% clover, 15% ryegrass, 15% purple amaranth, and 15% (volume percentage) of pachycarp, and the obtained plant juice After mixing in proportion, place it in a fermenter with a biological reaction system as a fermentation substrate. The fermenter is 15 tons. The plant juice mixed according to the formula ratio is used as a fermentation substrate of 13.5 tons, which is 0.2% of the total amount of fermentation substrate. First add Aspergillus niger strain SICC3.301, that is, the amount of koji added is 27 kg; temperature is 28°C-30°C, pH 6.5, and fermented for 24 hours; then add Lactobacillus plantarum SICC1 with 0.2% of the total amount of fermentation substrate. 518 kinds of koji, that is, the amount of koji added is 27 kg; the temperature is controlled at 38°C and fermented for 24 hours to obtain the fermentation culture liquid; the obtained fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com