Cementitious capillary crystalline waterproofing material

A technology of penetrating crystallization and waterproof materials, applied in the field of waterproof materials, can solve the problems of high price, achieve the effect of wide application range and protection from corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

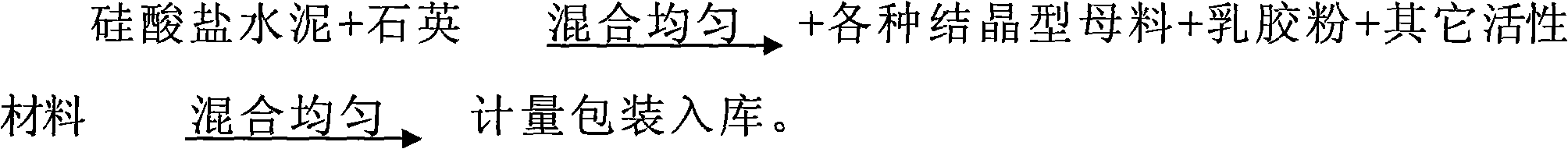

[0007] In the specific implementation, in terms of preparation, a dry powder mixing equipment with digital control and accurate measurement is used for mixing, and the best mixing speed and mixing time are determined to control the crystallization process in anticipation. The process route is as follows:

[0008]

[0009] In the embodiment, the performance of the tested material meets the requirements of GB18445-2001, the impermeability pressure ≥ 1.2Mpa, the secondary impermeability pressure (56d) ≥ 0.8Mpa, the penetration pressure ratio ≥ 300%, and the bonding strength of the mixed base surface ≥ 1.0Mpa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com