Detection method and dynamic-static state combined simulation multifunctional experimental system based on conductometric titration dirt property parameters

A characteristic parameter and conductometric titration technology, which is applied in the direction of material electrochemical variables and material resistance, can solve the problems of inability to measure the thickness of the scale layer, and the inability to accurately measure the calcium carbonate crystallization scale and particle scale induction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

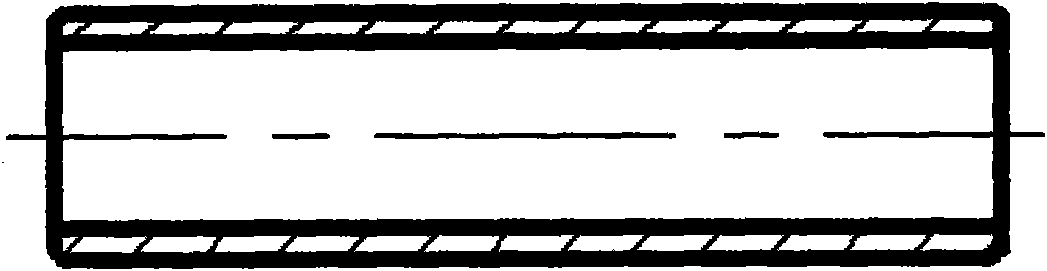

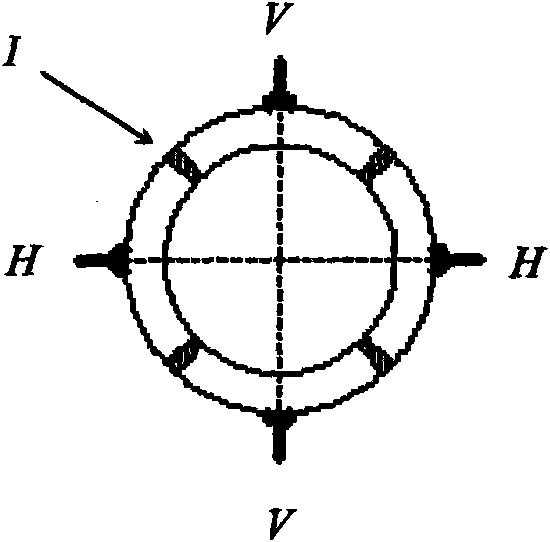

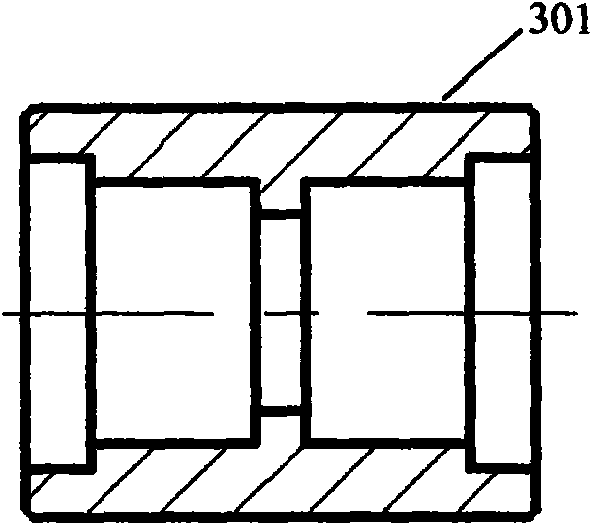

[0049] See figure 1 and figure 2 , the four-lobe arc tube dirt characteristic parameter detection sensor 8-1 provided by the present invention, 8-2 selects long 200mm for use, inner diameter 12mm, wall thickness 2mm, material is 20# low carbon steel pipe, stainless steel pipe or copper pipe as sensor main body , first divided into four equally divided points in the circumferential direction of its cross section, and divided into four equal lobes along the axial direction of two adjacent equal points, using wire cutting technology, each petal corresponds to a central angle of 90 degrees, adjacent to each other when cutting The order of the two petals is bonded together one by one, and an insulating layer I is set between each adjacent two petals. Make it meet the following process requirements: ①The roundness of the flow section in the pipe does not change before and after bonding; ②The inner diameter is basically equal before and after bonding. In this way, the upper and lo...

Embodiment 2

[0051] See Figure 5 , a dynamic and static joint simulation multifunctional experimental system of fouling characteristic parameters based on conductometric titration, which is composed of a tubular simulated heat exchanger, a titration device, a working fluid circulation system, a cooling system, and an online detection program; the tubular simulated heat exchanger The middle sections of two test tubes 7-1 and 7-2 of 11 are equipped with four-lobed arc tube dirt characteristic parameter detection sensors 8-1 and 8-2 respectively, and one end of the two test tubes 7-1 and 7-2 respectively It is connected to the bottom of the upper water tank 4 of the working medium circulation system, and the other end is respectively connected to the lower water tank 12 in the working medium circulation system; the bottom of the tubular simulated heat exchanger 11 is equipped with several parallel electric heating rods 9-1, 9 -2, 9-3, used to heat the temperature of the water bath to the exp...

Embodiment 3

[0060] See Figure 6 , dynamic and static joint simulation of dirt characteristic parameters based on conductometric titration. The online detection program in the multifunctional experimental system consists of system diagram, curve display, online calculation, parameter query, parameter setting, alarm record, operation record, report printing, manual data input, refresh It consists of functional modules such as saving, online help and exiting the system. The system diagram function module is used to display the structural diagram of the entire detection system; the curve display function module has two sub-modules, the historical curve and the real-time curve, and any module is equipped with a "display parameter selection bar", including dirt thermal resistance, conductivity , temperature and other parameters, select the option to be displayed from the "A tube" or "B tube" box, click the "OK" button, the graphic display window will display the corresponding curve; the online...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com