EMC inductor and manufacturing method thereof, EMI filter and switching power supply

A production method and technology of inductors, which are applied in transformers/inductor coils/windings/connections, inductors with magnetic cores, electrical components, etc., can solve problems such as filter design difficulties, improve anti-interference ability, and improve filtering effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

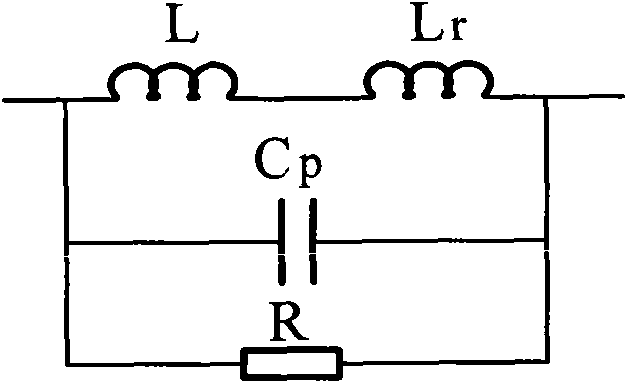

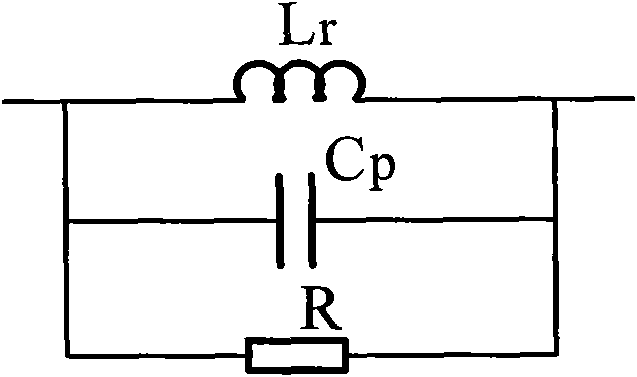

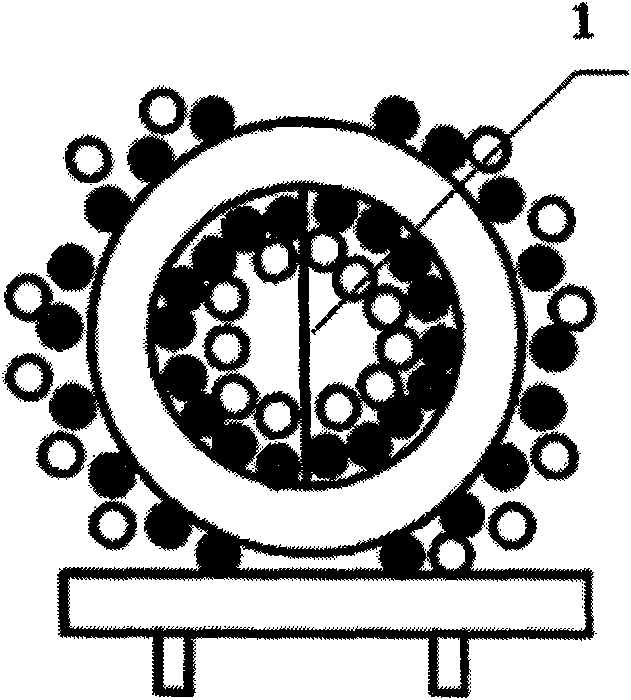

[0034] image 3 An EMC inductor of this embodiment is shown, which is a common mode inductor using a common ferrite core. The ferrite core is ring-shaped, and the winding includes a first winding layer and a second winding layer wound on the ferrite core. The first winding layer is evenly surrounded by the magnetic core, and the second winding layer is wound outside of the winding layer. In addition, an isolation baffle 1 for the common mode inductor is provided in the middle of the magnetic core, which is mainly provided for the convenience of processing the common mode inductor. The lead inductance and inter-turn capacitance generated by the first and second winding layers make the second resonance frequency of the common mode inductor in the 10MHz~200MHz frequency band, so that the common mode inductor has high impedance characteristics in this frequency band, so it can effectively suppress the high frequency in this frequency range. Frequency disturbance frequency point....

Embodiment 2

[0042] Please refer to Figure 6 , similar to the common mode inductor in Embodiment 1, the winding of the inductor includes a first winding layer and a second winding layer wound on a ferrite core, the first winding layer is evenly surrounded by the magnetic core, and the second winding layer Wrap around the outside of the first winding layer. The difference from Embodiment 1 is that an insulating layer 5 is added between the first winding layer and the second winding layer, and the insulating layer can be made of insulating tape or similar materials, so as to adjust the inter-turn capacitance Cp, and thus achieve the adjustment The role of the second resonance frequency point of the common mode inductor. Specifically, a layer of insulating tape 5 with a thickness of 0.15 mm is added between the two layers. In this embodiment, the first resonant frequency of the common mode inductor is set at about 400 KHz, the second resonant frequency is set at about 35 MHz, and the bandw...

Embodiment 3

[0045] Please refer to Figure 7 , and the difference from Embodiments 1 and 2 is that the winding of the common mode inductor includes not only the first and second winding layers, but also a third winding layer, which successively overlaps three layers on the magnetic core. The second resonant frequency point of the inductor can also be easily changed by increasing the number of winding layers. In this embodiment, the first resonant frequency of the common mode inductor is set at about 400 KHz, the second resonant frequency is set at about 35 MHz, and the bandwidth is about 10 MHz.

[0046] Similar to Example 1, please refer to the manufacturing steps of the common mode inductor Figure 5 . Wherein, in this embodiment, a winding layer is added without changing the winding leads. Compared with the two-layer stacked winding method, the three winding layers are concentratedly wound on part of the arc section of the toroidal core, the area of the wound core is reduced, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com