Technological method of clamping device of multi-position cross-shaft processing machine

A technology of clamping device and process method, which is applied in positioning devices, metal processing machinery parts, metal processing equipment and other directions to achieve the effects of reducing processing procedures, improving processing efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

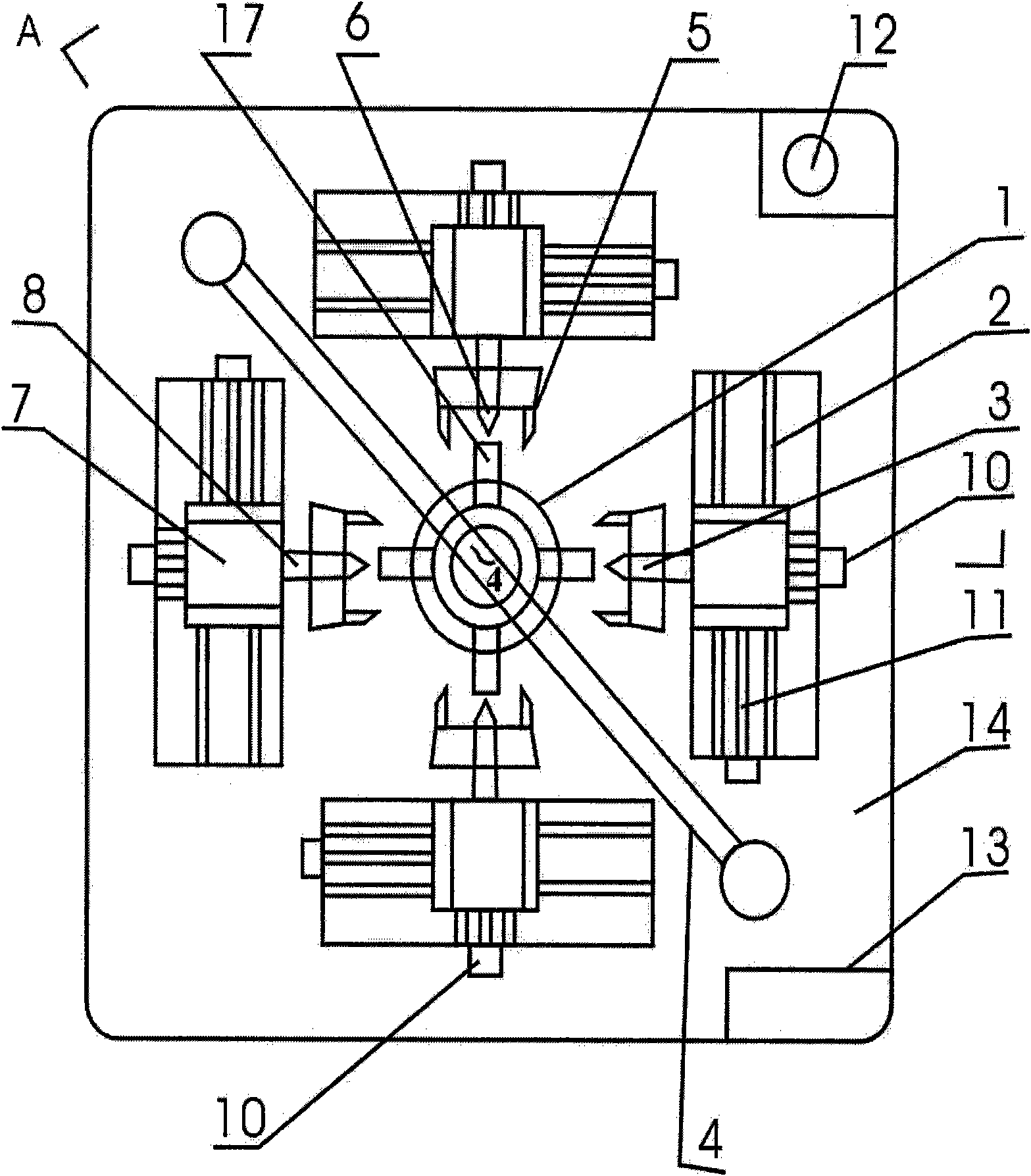

[0030] The object of the present invention is achieved by the following examples.

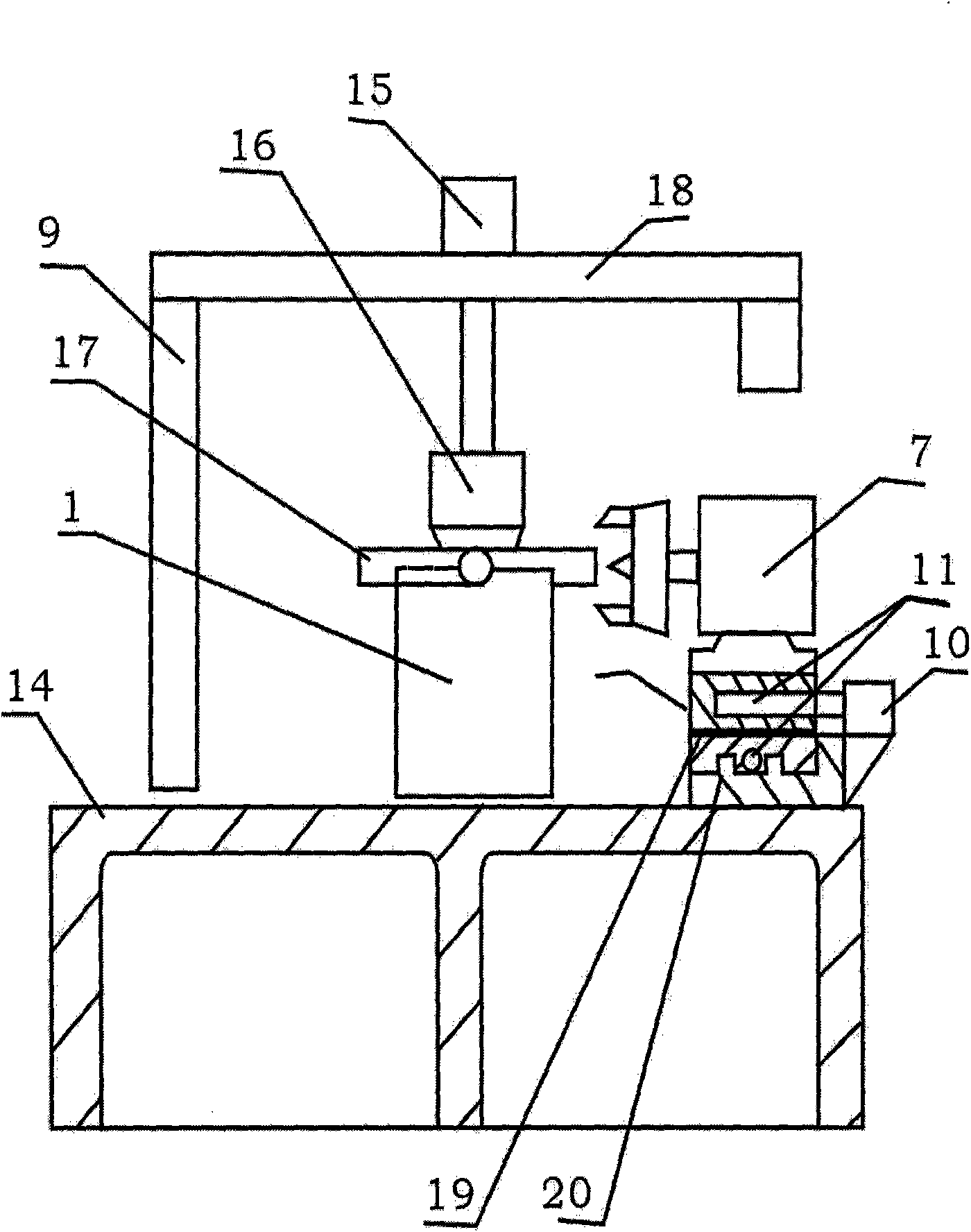

[0031] A. Cross shaft positioning and clamping, fix the support seat at the center of the bed table, and fix four V-shaped groove positioning blocks arranged in a cross shape on the support seat. The intersection of the center lines of the V-shaped grooves is 90°±0.1, and the cross shaft After entering, the self-centering is positioned in the four V-shaped grooves, and then a hydraulic cylinder is used to drive the clamping device on the cross shaft to press and fix the cross shaft.

[0032] B. The rotation of the main shaft is controlled by a frequency conversion servo motor, which can realize stepless speed regulation, so as to meet the changing requirements of different main shaft rotation speeds for milling and drilling. A cutter head is fixed on the main shaft, and a milling cutter and a center drill are installed on the main shaft cutter head. Motor Fixed on the horizontal guide rail, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com