Method for manufacturing hollow medium density fiberboards and special equipment

A manufacturing method and technology of special equipment, applied in applications, household components, flat products, etc., can solve the problems of high fiber material consumption, high cost, and heavy board weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

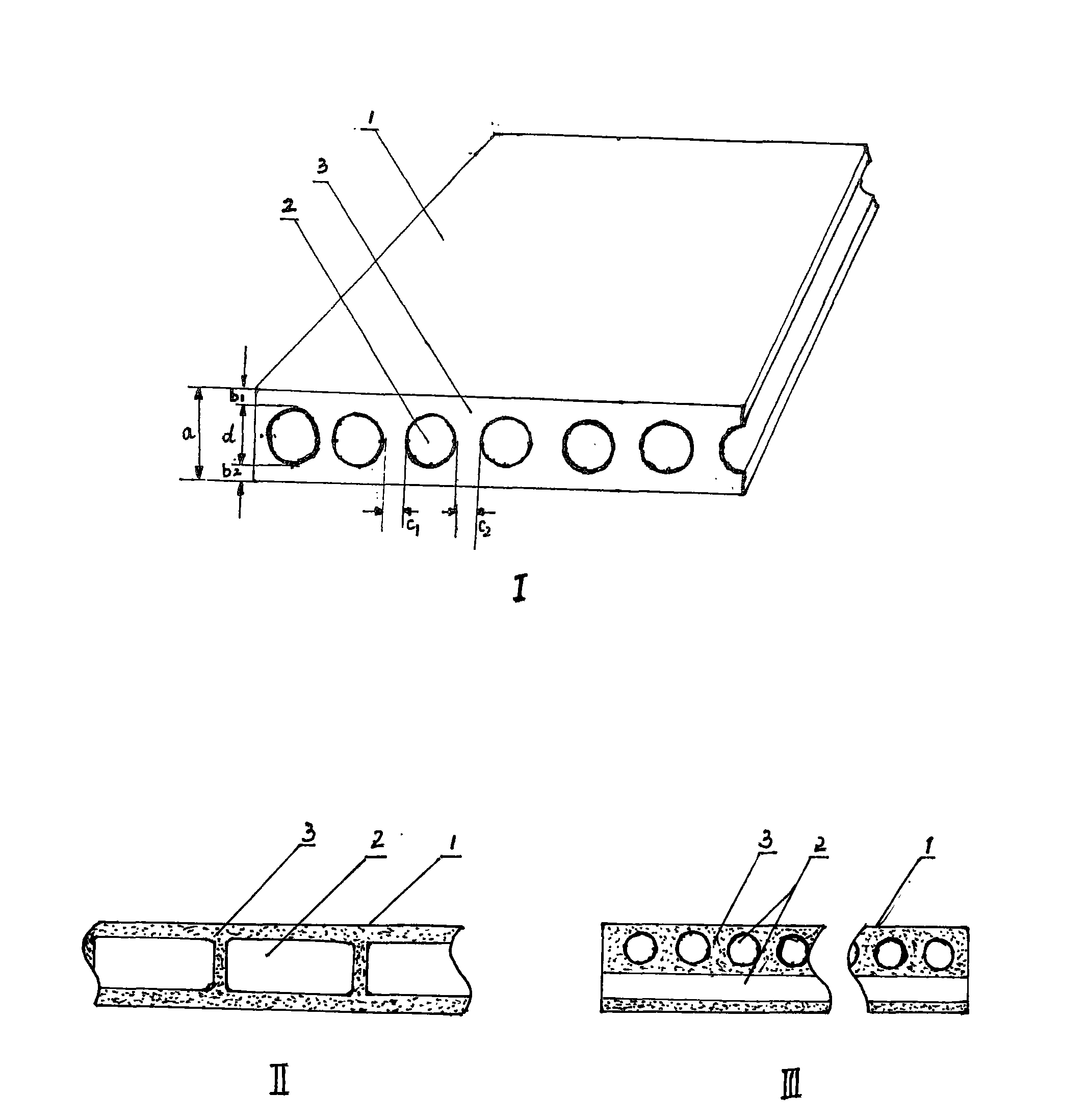

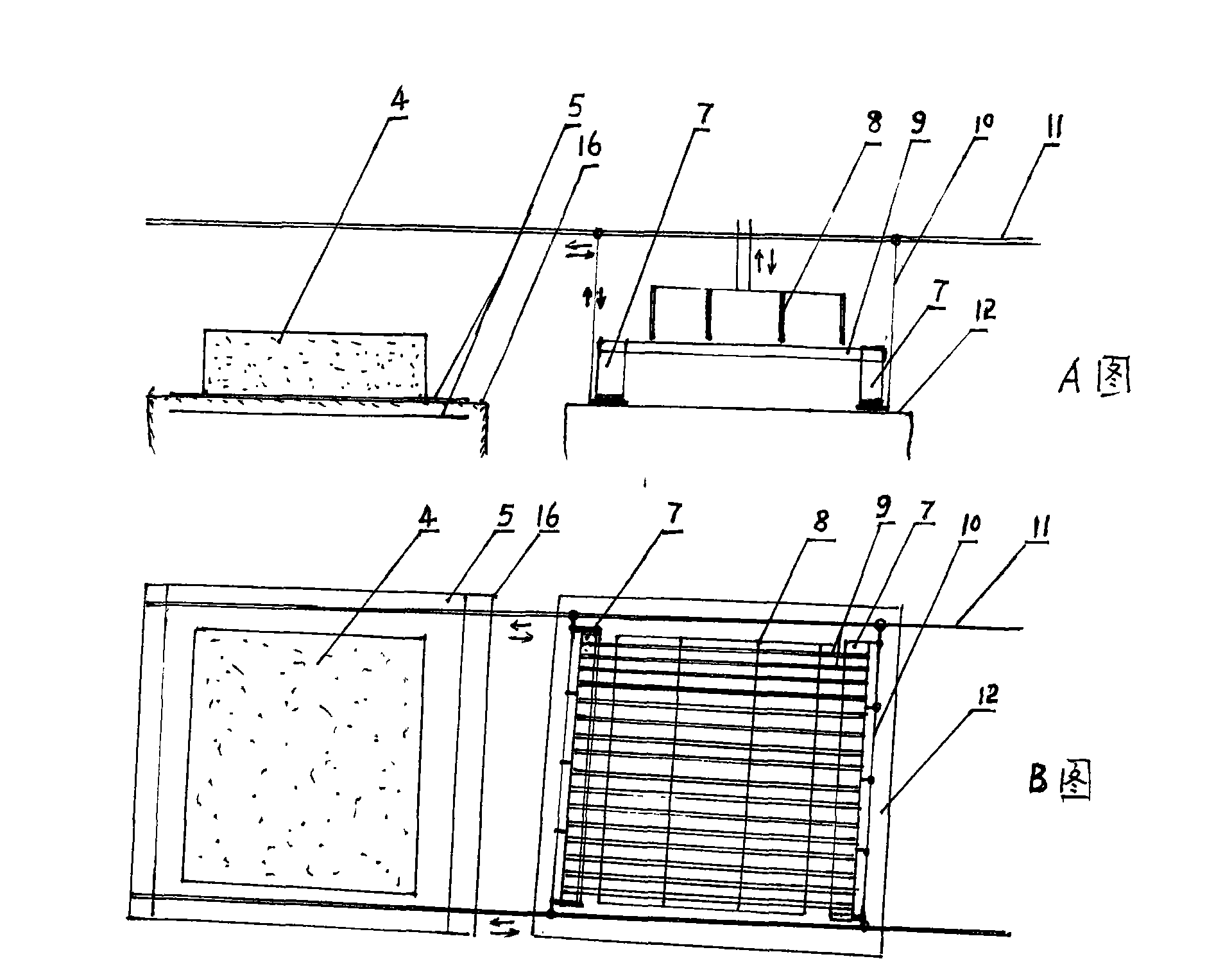

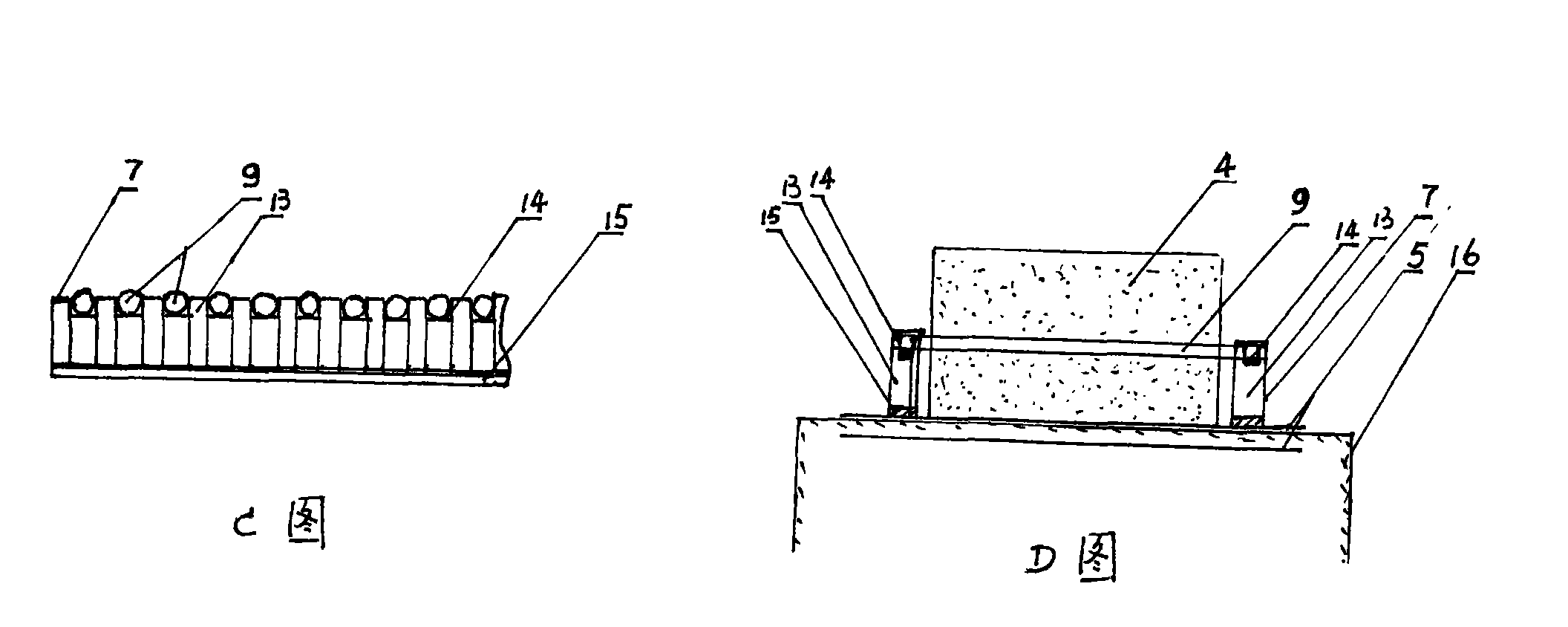

[0074]Embodiment 1: A kind of manufacturing method of hollow medium density fiberboard, comprises material preparation, fiber separation (cooking, thermal grinding), fiber treatment (application of melamine modified urea-formaldehyde resin glue, paraffin water repellent, drying), fiber base board laying slab preloading, slab longitudinal trimming, horizontal sawing, slab transportation, use one or several sets of long bar loading devices, and equip a long bar positioning device to place several steel long bars horizontally or Place it vertically and press it into the base plate, and send the base plate pressed into the long bar to be leveled or not leveled and sent to a multi-layer hot press for hot pressing. The hot pressing process is carried out according to the process parameters of conventional medium density fiberboard. The time can be appropriately shortened to take into account that the heat transfer of the long steel bar accelerates the solidification speed of the plat...

Embodiment 2

[0075] Embodiment 2: The method of putting in the long bar is to use the long bar inserting device to insert the long bar into the base plate and cooperate with the long bar positioning device. Others are with embodiment 1.

Embodiment 3

[0076] Embodiment 3: the method for putting into long strips is that the fiber pavement is made into approximately half of the fiber slab bands, after pre-pressing, longitudinal trimming and transverse sawing, some slabs are used as the lower slabs, and some The slab is used as the upper slab, and several long steel bars are placed on the lower slab with a long bar loading device. The long bars are large at one end and small at the other end. The size of the long bars is coated with mineral oil. Long bar positioning device, and then use the upper blank plate transfer device to transfer the upper blank plate to the lower blank plate on which the long bar has been placed, and form a whole blank plate. The upper blank plate receiving device is a trolley or a belt conveyor belt Push the flat plate of the slab, pass the slab conveyor and the transition plate-the slab conveying line, send the slab to the multi-layer or single-layer hot press for hot pressing, press it into a slab, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com