Microbe fuel cell inoculation and acclimation starting method for energizing organic waste water

A technology of organic wastewater and fuel cells, applied in biochemical fuel cells, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems affecting the application of microbial fuel cell technology, enrichment and acclimation time of electrogenic bacteria, and too long start-up time and other problems, to achieve the effect of stable domestication process, easy implementation, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

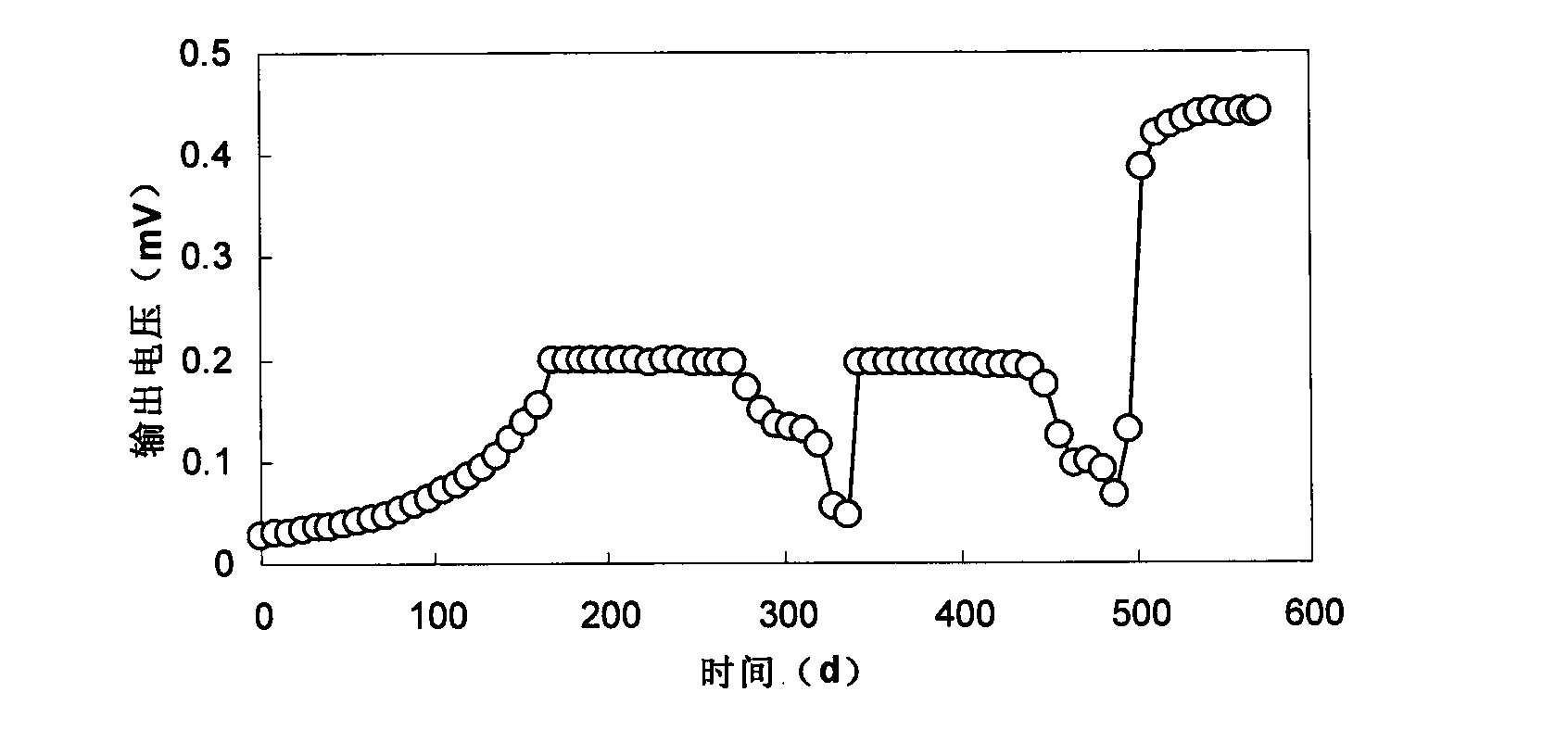

[0036] Use microbial fuel cells to treat domestic sewage and recover electrical energy.

[0037] 1) For the preparation of mixed strains, take the soil supernatant, add 1g / L sodium acetate solution to the soil supernatant according to the volume ratio of 10%, and put it in an anaerobic incubator for storage for later use;

[0038] 2) Select a microbial fuel cell with an effective volume of the anode and cathode reaction chambers of 200ml and a distance between the cathode and anode of 5cm;

[0039] 3) Inject 1g / L sodium acetate solution and 150ml and 50ml of the mixed strain solution prepared in step 1) into the anode, and add N, P, and K elements, and the concentrations are 80mg / L, 5000mg / L and 3000mg respectively / L, inject 200ml of 100mg / L sodium nitrate solution into the cathode;

[0040] 4) The 1000Ω resistor is connected to the external circuit, and the wire and monitoring equipment are connected;

[0041] 5) Place it at room temperature until the voltage starts to sta...

Embodiment 2

[0044] The difference from Example 1 is that the treated wastewater is soy sauce brewing wastewater, and volatile gases are regularly discharged during operation.

[0045] 1) For the preparation of mixed strains, take the soil supernatant, add 1g / L sodium acetate solution to the soil supernatant according to the volume ratio of 10%, and put it in an anaerobic incubator for storage for later use;

[0046] 2) Select a microbial fuel cell with an effective volume of the anode and cathode reaction chambers of 200ml and a distance between the cathode and anode of 5cm;

[0047] 3) Inject 1g / L sodium acetate solution and 150ml and 50ml of the mixed strain solution prepared in step 1) into the anode, and add N, P, and K elements, and the concentrations are 80mg / L, 5000mg / L and 3000mg respectively / L, inject 200ml of 100mg / L sodium nitrate solution into the cathode;

[0048] 4) The 1000Ω resistor is connected to the external circuit, and the wire and monitoring equipment are connected...

Embodiment 3

[0052] The difference from Examples 1 and 2 is that the electrogenic bacteria used are collected from activated sludge of a wastewater treatment plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com