A metallic apparatus that can promote thermal conduction and coating method

A technology of heat conduction and appliances, which is applied in the field of appliances containing thermal conductivity catalysts and their coatings. It can solve the problems that the composition of the coating layer has no properties, does not have beneficial characteristics for the human body, and stays on the surface of the protective appliance. Achieve the effects of shortening the preheating time, excellent wear resistance, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

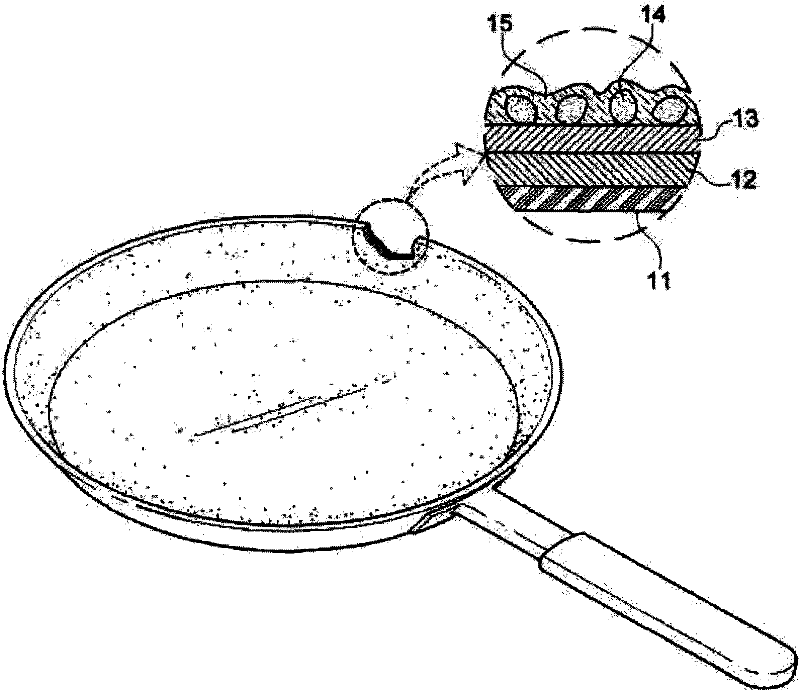

[0029] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the attached drawings.

[0030] First of all, it should be noted that in the drawings, the same constituent elements or components are denoted by the same symbols as much as possible. In the description of the present invention, specific descriptions of related known functions or configurations are omitted in order not to obscure the subject matter of the present invention.

[0031] The terms "about" and "substantial" used in this specification refer to the inherent manufacturing and material tolerances, and are used in the meaning of their numerical values or close to their numerical values. This is to It is used to help a correct understanding of the present invention, or to prevent unscrupulous infringers from improperly using the disclosure of absolute numerical values involved.

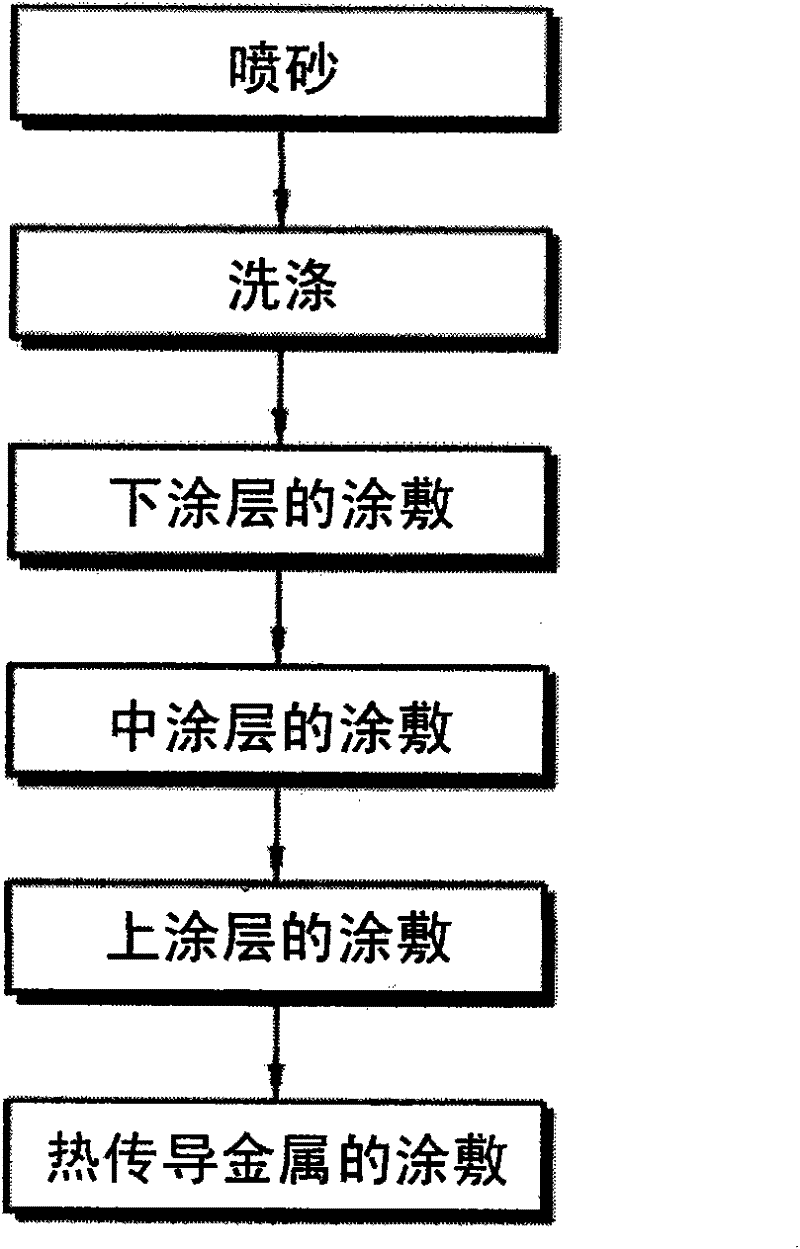

[0032] figure 2 It is a block diagram showing the coating steps of the app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com