Method for eliminating defect of strip shape of hot-rolled high-strength steel

A high-strength steel plate and defect technology, which is applied in the field of eliminating shape defects of hot-rolled high-strength steel plates, can solve the problems of not being able to obtain flat and stable plate shape quality, and cannot be completely eliminated, so as to achieve high plate shape quality requirements and low internal stress. Improvement of distribution uniformity and improvement of surface quality

Active Publication Date: 2011-01-26

SHOUGANG CORPORATION

View PDF10 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0018] Roller leveling technology can eliminate type A) shape defects, but cannot completely eliminate type B) defects, and cannot obtain flat and stable shape quality

If it is necessary to completely eliminate the above two types of plate shape defects, the stretch bending straightening machine or skin pass unit is a very good tool, but it is only used in large quantities in the production process of cold-rolled strip steel, such as 200620092768.7, 200510024681.6, etc. Patent for leveling or tension leveling process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0122] In May 2009, the test of residual stress relief of hot continuous rolling high-strength steel coils was carried out at Qiangang, Shougang. Two coils of SQ600MCD were rolled on the 2250mm hot continuous rolling production line of Shougang Qiangang. The specific shape is also similar: when the two steel coils are rolled, they are all in the shape of a medium wave with a head of 100 to 300IU, and the follow-up is an edge wave shape.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

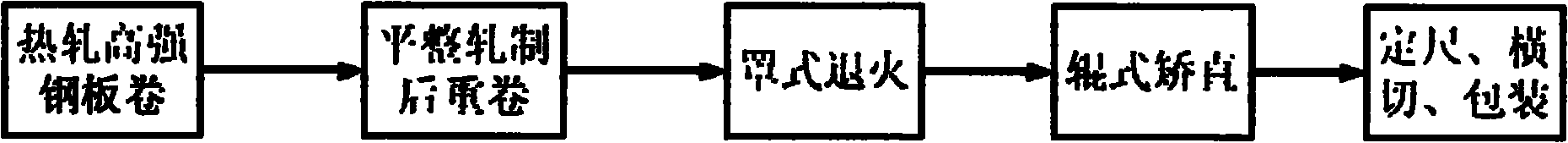

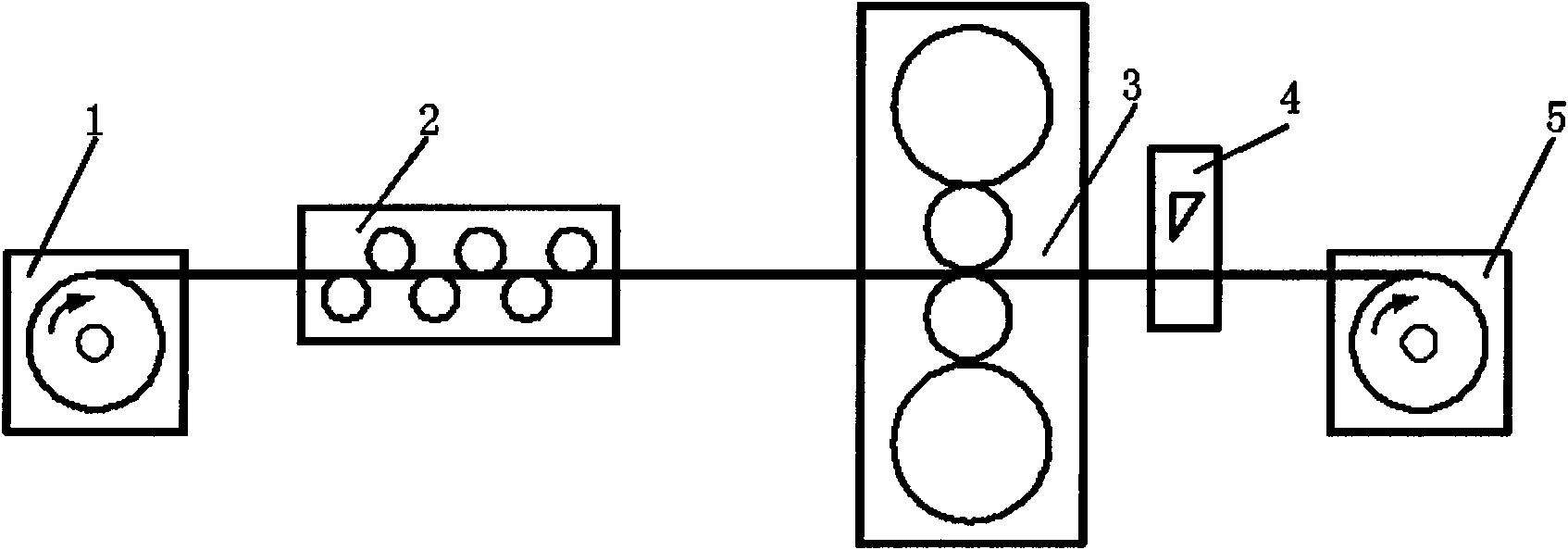

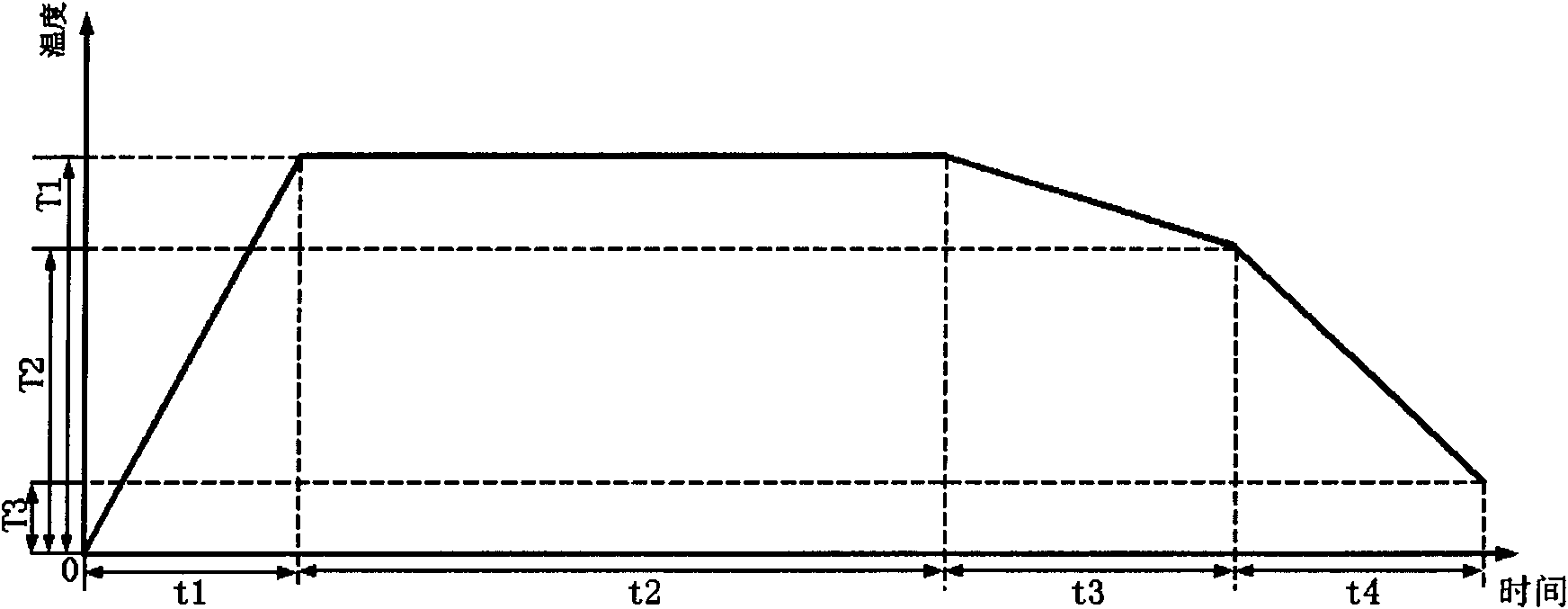

The invention relates to a method for eliminating a defect of strip shape of hot-rolled high-strength steel. The technological combination of skin rolling, batch annealing and roll straightening is introduced into a process for the plate rolling of the hot-rolled high-strength steel with a specification range of 3-18.4mm multiplied by 900-1800mm (thickness multiplied by width) and a yield strength not less than 600MPa, so as to eliminate an internal stress of the hot-rolled high-strength steel, obviously improve the shape quality, and enable a user to obtain good shape stability, which is capable of meeting the strict requirement of the user that the flatness is less than or equal to 2mm / m.

Description

technical field [0001] The invention belongs to the technical field of steel processing methods, and relates to a method for eliminating shape defects of hot-rolled high-strength steel plates, and is particularly suitable for eliminating the rolling process, laminar cooling process, coiling and subsequent cooling process of high-strength steel with a yield strength greater than 600 MPa Potential shape defects caused by the residual stress generated in the steel sheet can improve the shape quality of hot-rolled high-strength steel sheets. Background technique [0002] The shape of hot-rolled strip is a quality index that users are increasingly demanding, which affects the processing efficiency of strip flattening, cutting and blanking, and subsequent welding processes as well as the final product quality. Severe plate shape defects may lead to problems such as delayed production, damage to processing equipment, and welding difficulties when users use it. Especially for produ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B37/28C21D8/02C21D9/663B21D1/06

Inventor 王晓东赵林李飞刘建辉张鹏程李明余威金永春武军宽潘辉周德光马耀峰李彬孟宪堂

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com