Easy-cutting untempered steel and method for manufacture thereof

A non-quenched and tempered steel, easy-cutting technology, applied in the field of metallurgy, to achieve good surface roughness, improve adverse effects, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

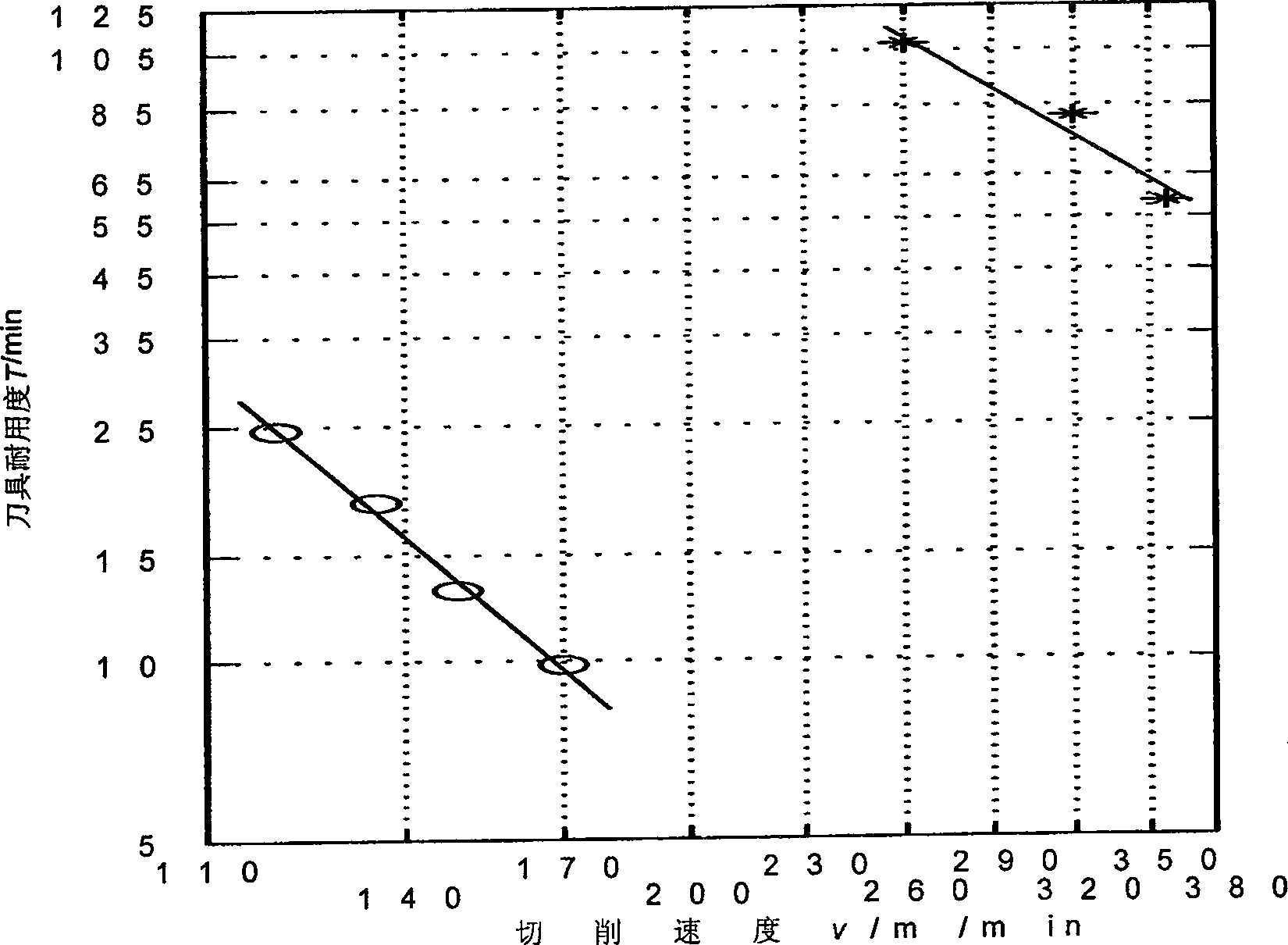

Image

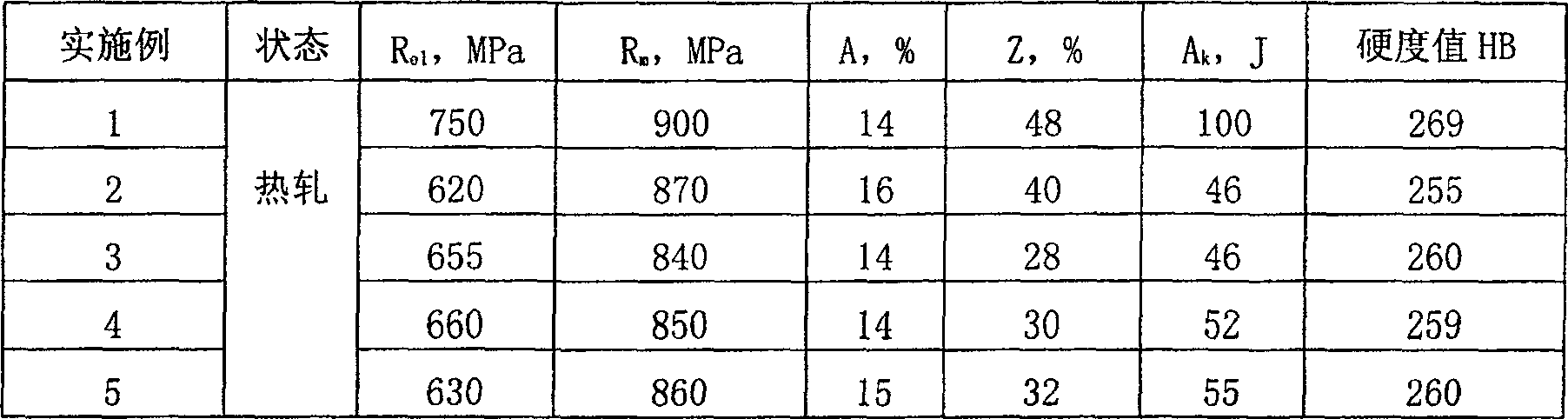

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be specifically described below in conjunction with the embodiments and drawings, but are not limited thereto.

[0046] The Ca-S composite free-cutting non-quenched and tempered steel used for cutting in the present invention is smelted by UHP (overpower electric furnace) + LF (extra-furnace refining) process, continuous casting casting billet-heating-rolling finished product-rolling controlled cooling process Production of steel. Embodiments 1-5 specifically illustrate how the present invention is implemented with the production process of Φ50mm steel.

[0047] The production process steps of Ca-S composite free-cutting non-quenched and tempered steel for cutting are as follows:

[0048] (1) Smelting and alloying, electric furnace smelting, tapping, LF refining outside the furnace. In order to ensure the form of easy-cutting inclusions in the steel, the smelting technology is adopted to add S wire to the steel fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com