Necking machine for copper pipe

A technology of necking and copper tube, applied in the direction of metal processing machinery parts, clamping, supporting, etc., can solve the problems of inconvenient production, increased process, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with the embodiment given with accompanying drawing.

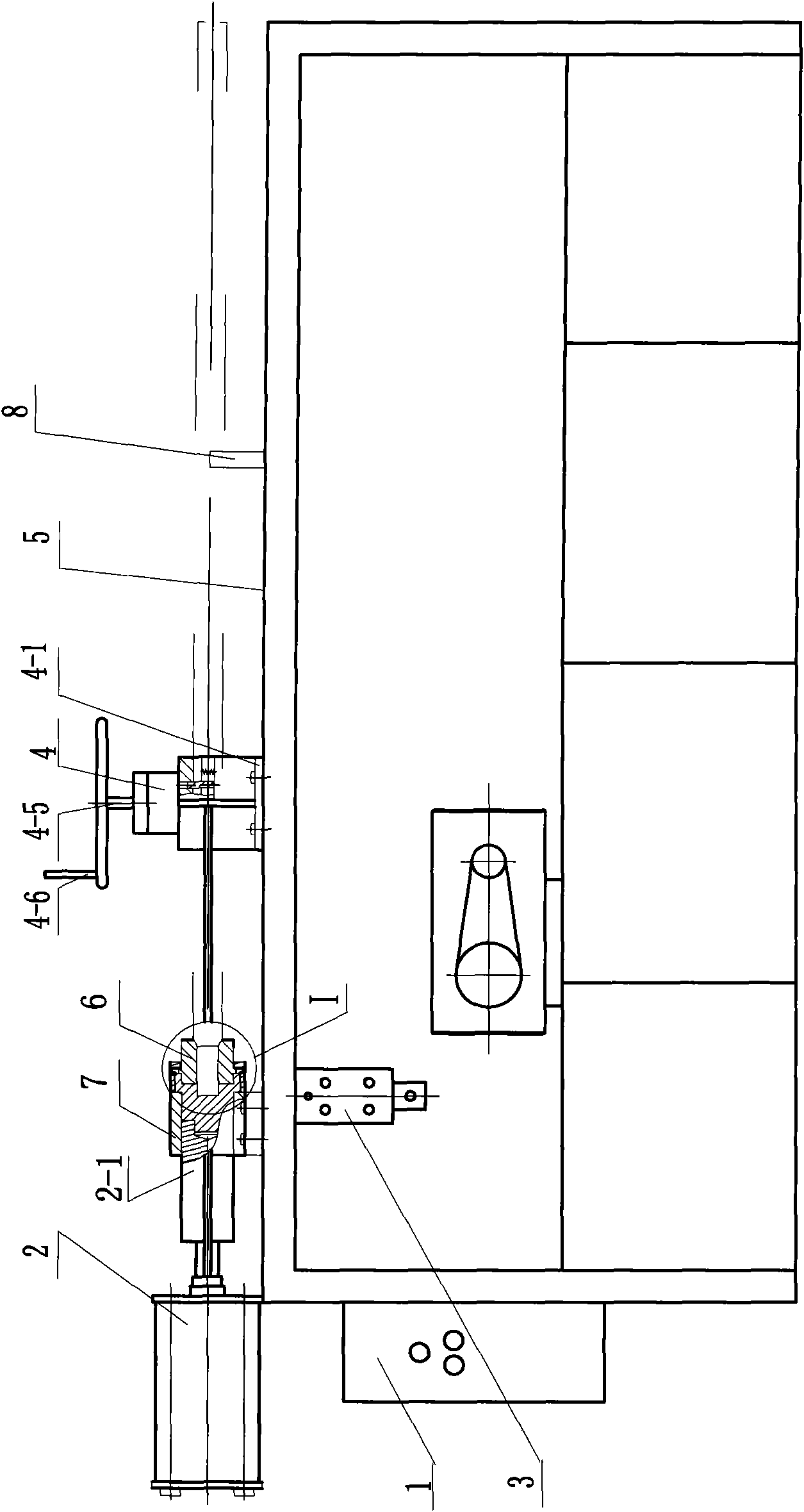

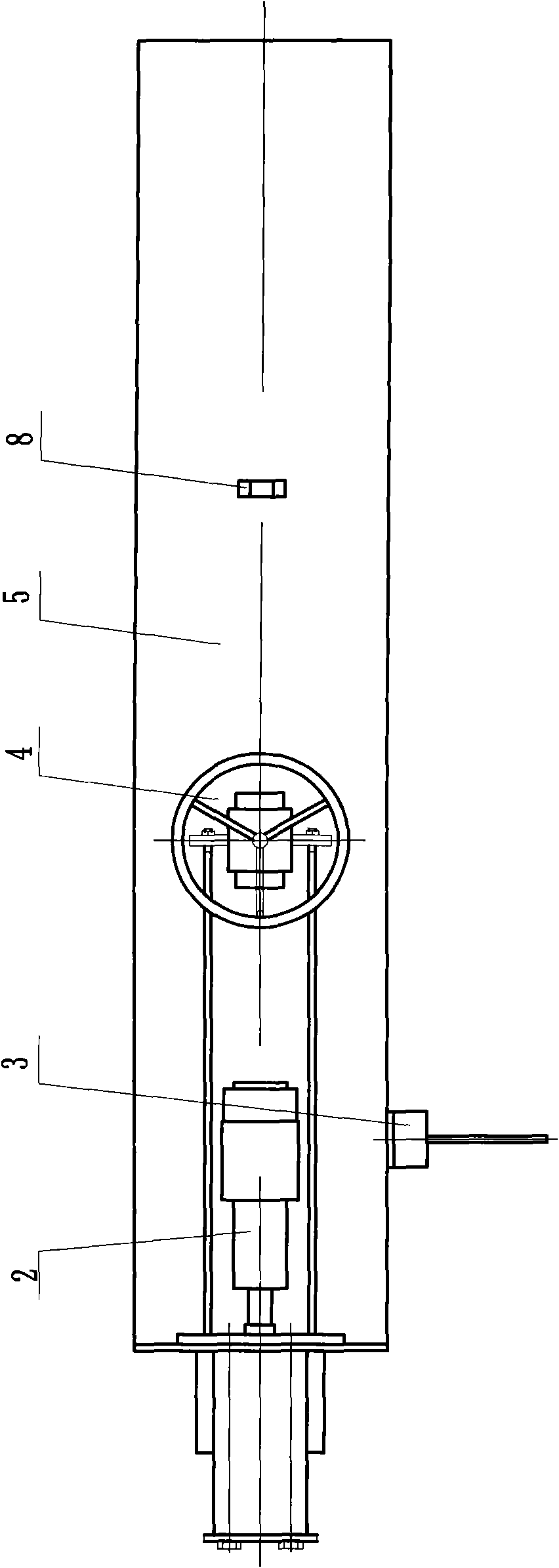

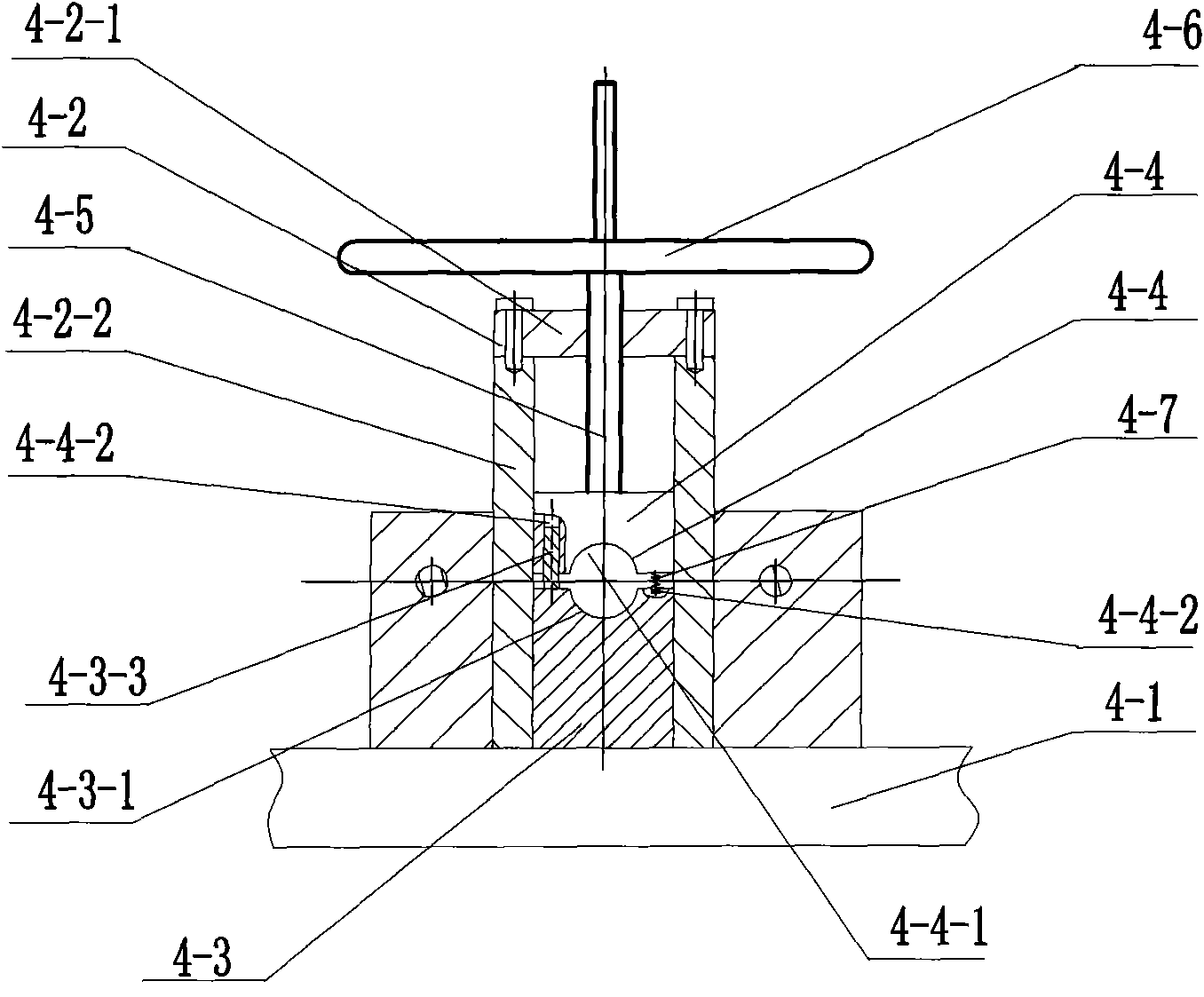

[0018] see figure 1 , 2 , 3, 4, a copper tube shrinking machine, including workbench 5, hydraulic cylinder 2, manual reversing valve 3, locking fixture 4, support seat 7 and control box 1, control box 1 controls hydraulic cylinder 2 to work, The manual reversing valve 3 can control the movement direction of the piston in the hydraulic cylinder 2. The hydraulic cylinder 2, the manual reversing valve 3, the locking fixture 4, the support seat 7 and the control box 1 are all connected to the workbench 5 and locked. The center line of the clamp 4 is consistent with the center line of the hydraulic cylinder 2. The hydraulic cylinder 2 has a shaft 2-1 protruding from the outer end of the oil cylinder. The shaft 2-1 is slidably fitted with the inner hole of the support seat 7, and a shrinking mold is also included. 6. The necking mold 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com