Iron-based abrasion resistant overlaying-welding flux-cored wire

A technology of welding wire and flux, applied in the field of iron-based wear-resistant surfacing flux-cored welding wire, can solve the problems of high cost, mismatch of hardness and toughness, etc., and achieve the effects of low cost, excellent wear resistance, and low crack sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An iron-based wear-resistant surfacing flux-cored wire, the composition of which is: carbon C 0.9%, boron B 2.5%, titanium Ti 2.0%, vanadium V 1.0%, silicon Si 1.0%, manganese Mn 1.2%, rare earth 0.05%, chromium Cr 1.3%, molybdenum Mo 0.3%, and the balance is iron.

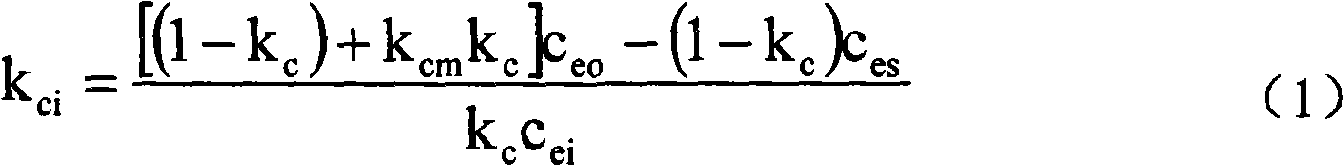

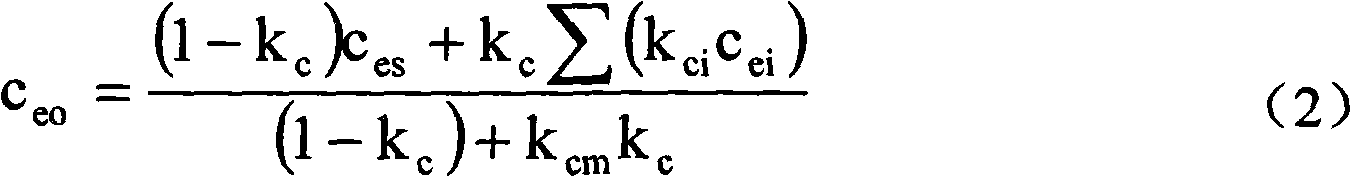

[0038] The outer sheath of the welding wire is made of H08A thin steel strip specially used for welding wire. The thin steel strip has a width of 16mm and a thickness of 0.3mm, and its composition is 0.08%C, 0.4%Mn, 0.10%Cr, and 0.15%Ni. The flux core can be mixed with special alloy powder for welding wire, and the filling factor is 35%. Cerium compound powder, chromium ferroalloy powder, molybdenum ferroalloy powder, etc., these alloy powders are fully mixed evenly, and the amount of each alloy powder is calculated according to formula (1) and formula (2). No slagging agent is added.

[0039] The main method of producing flux-cored welding wire in my country-steel strip method is used to produce welding ...

Embodiment 2

[0042] An iron-based wear-resistant surfacing flux-cored wire, the composition of which is: carbon C 0.3%, boron B 6.5%, titanium Ti 0.5%, vanadium V 1.5%, silicon Si 1.0%, manganese Mn 1.2%, rare earth 0.04%, Chromium Cr 1.0%, molybdenum Mo 0.3%, and the balance being iron.

[0043] The welding wire sheath is made of special H08A thin steel strip for welding wire. The thin steel strip has a width of 16mm and a thickness of 0.3mm. The flux core can be mixed with special alloy powder for welding wire, and the filling factor is 35%. Cerium compound powder, chromium ferroalloy powder, molybdenum ferroalloy powder, etc., these alloy powders are fully mixed evenly, and the amount of each alloy powder is calculated according to formula (1) and formula (2). No slagging agent is added.

[0044] The main method of producing flux-cored welding wire in my country-steel strip method is used to produce welding wire. The process flow is: tie the thin steel strip into U shape, add flux cor...

Embodiment 3

[0047] An iron-based wear-resistant surfacing flux-cored wire, the composition of which is: carbon C 0.65%, boron B 4.0%, titanium Ti 3.5%, vanadium V 0.5%, silicon Si 0.6%, manganese Mn 1.2%, rare earth 0.02%, chromium Cr 1.0%, molybdenum Mo 0.8%, balance iron.

[0048] The welding wire sheath is made of special H08A thin steel strip for welding wire. The thin steel strip has a width of 16mm and a thickness of 0.3mm. The flux core can be mixed with special alloy powder for welding wire, and the filling factor is 35%. Cerium compound powder, chromium ferroalloy powder, molybdenum ferroalloy powder, etc., these alloy powders are fully mixed evenly, and the amount of each alloy powder is calculated according to formula (1) and formula (2). No slagging agent is added.

[0049] The main method of producing flux-cored welding wire in my country-steel strip method is used to produce welding wire. The process flow is: tie the thin steel strip into U shape, add flux core powder, sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com