New uranium mining method-plant uranium mining method

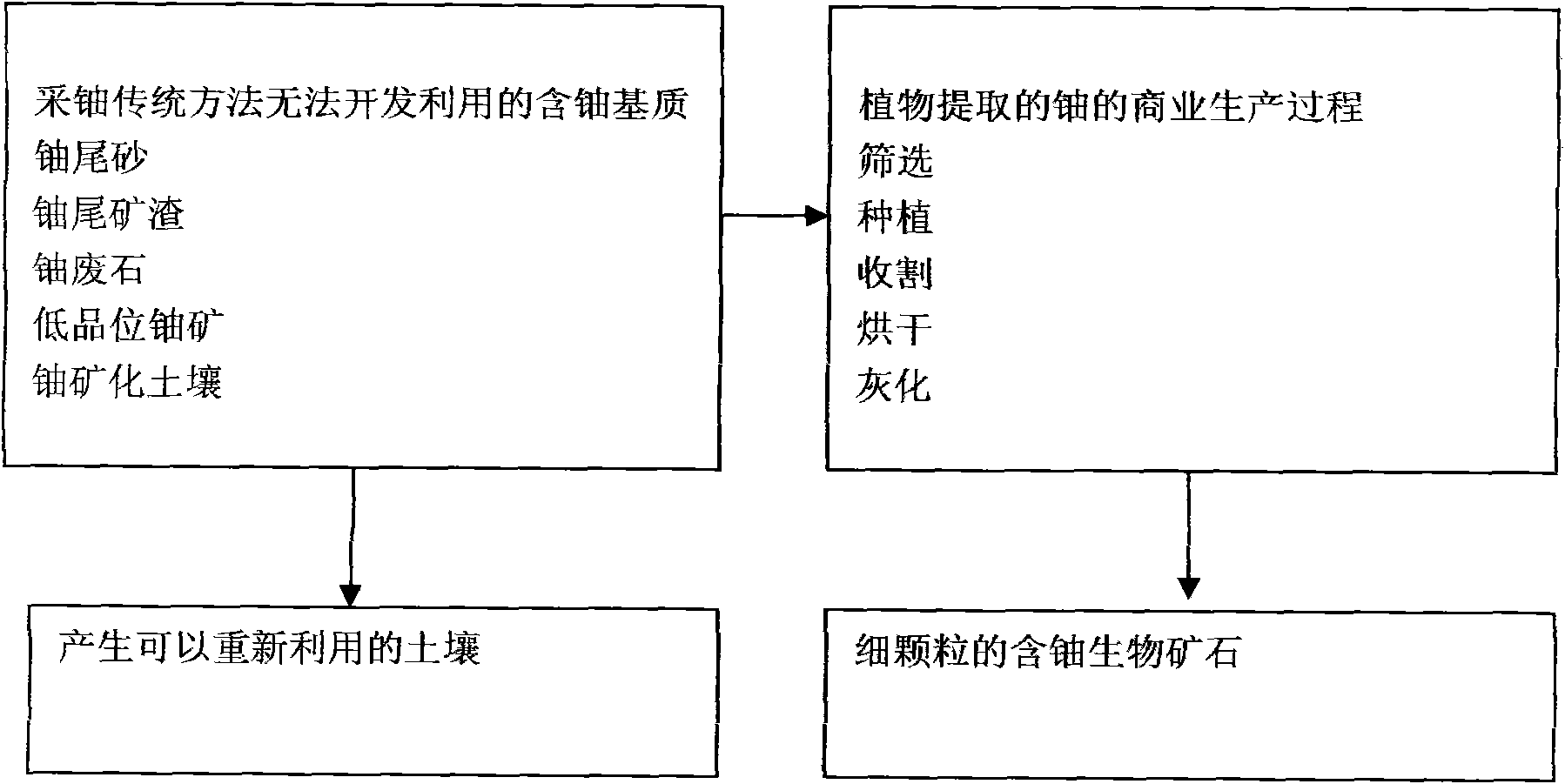

A mining method and uranium ore technology, applied in concentrated fields, can solve the problems of inability to develop and utilize, low uranium grade, etc., and achieve the effects of slowing down the greenhouse effect, beautifying the visual environment, and speeding up the ecological cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] A uranium enrichment plant that uses large biomass to enrich uranium from uranium tailings piled on the surface to the aboveground part of the plant. A method of incineration to form uranium-containing bioores. The specific steps are:

[0049] (1) Investigate, collect and analyze the uranium content of the dominant plants growing in the uranium tailings pool, screen the enrichment plants with high biomass uranium, and collect the seeds.

[0050] (2) Preserve the seeds, recover the seeds in the spring of the coming year, and first use HgCl 2 Disinfect for about 5 minutes, then wash with tap water, and finally germinate the seeds.

[0051] (3) Adopt the sand culture method to grow seedlings, deposit 30 seeds in every petri dish, and the whole test is carried out in an artificial climate room with a constant temperature of 28° C., a relative humidity of 80%, a light length of 14 hours, and an illumination intensity of 1500 lx.

[0052] (4) When the seedlings grow to a c...

Embodiment 1

[0058] Embodiment 1, water sedge seeds are treated with HgCl 2 Treat for about 5 minutes, then rinse with tap water, use the sand culture method to grow seedlings, and when the seedling age reaches 10 days, transplant the seedlings to a uranium tailings bank, manage carefully, fertilize reasonably, and harvest the aboveground parts after 100-120 days. Air-dried at room temperature, crushed, put into a high-temperature furnace at 600°C for incineration, and collected residual ash, that is, bio-ore containing uranium. After analysis and determination, the grade of bio-ore containing uranium was 0.15%.

Embodiment 2

[0059] Embodiment 2, oat seeds are treated with HgCl 2 Treat for about 5 minutes, then rinse with tap water, use the sand culture method to grow seedlings, and when the seedling age reaches 15 days, transplant the seedlings to a uranium tailings bank, manage carefully, fertilize reasonably, and harvest the aboveground parts after 100-120 days. Air-dried at room temperature, crushed, put into a high-temperature furnace at 600°C for incineration, and collected residual ash, that is, uranium-containing bio-ore. After analysis and determination, the grade of uranium-containing bio-ore was 0.045%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com