Measurement method of thickness of subsurface damaged layer of bucky optical material

A technology of subsurface damage and optical materials, applied in the direction of measurement devices, optical devices, and material analysis using radiation diffraction, etc., can solve problems such as unexplained measurement, unintuitive image processing results, and complicated use and debugging of optical microscopes. Achieve the effect of high precision and strong engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

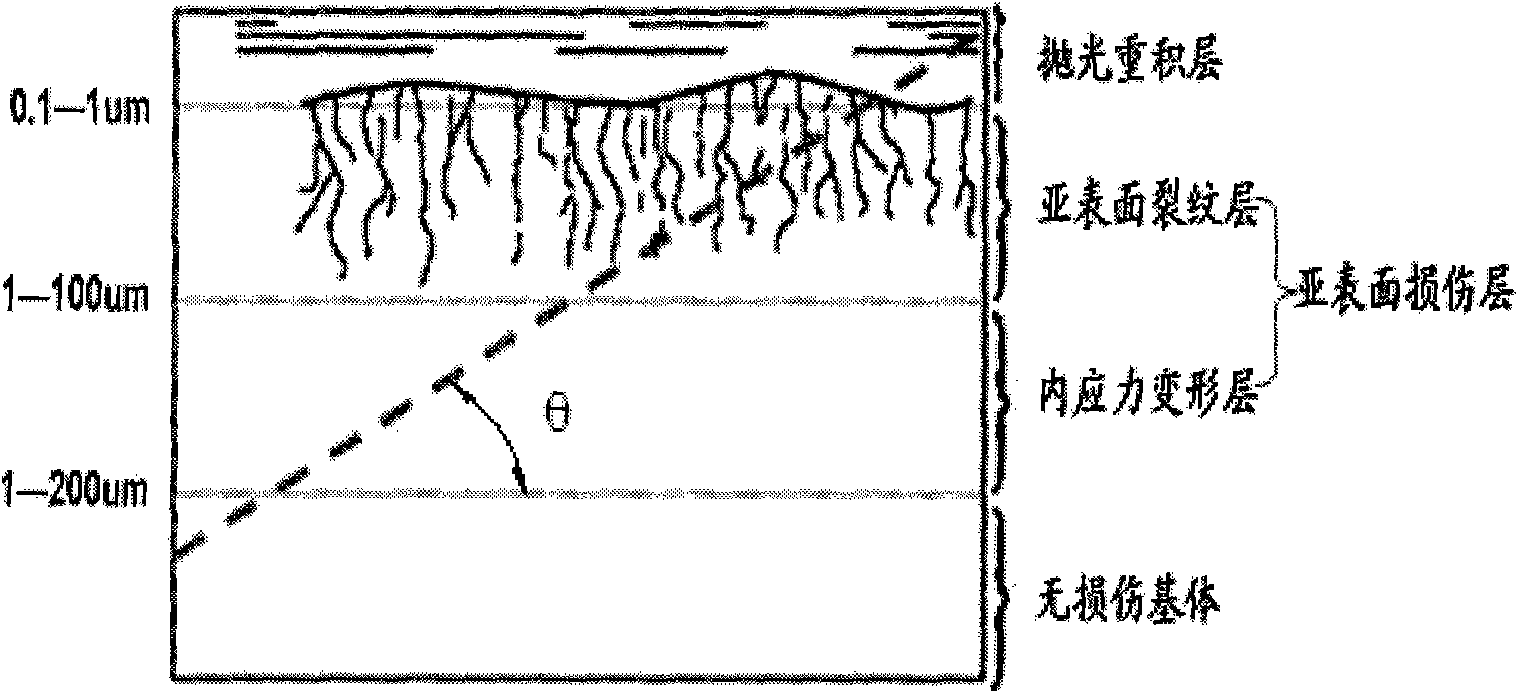

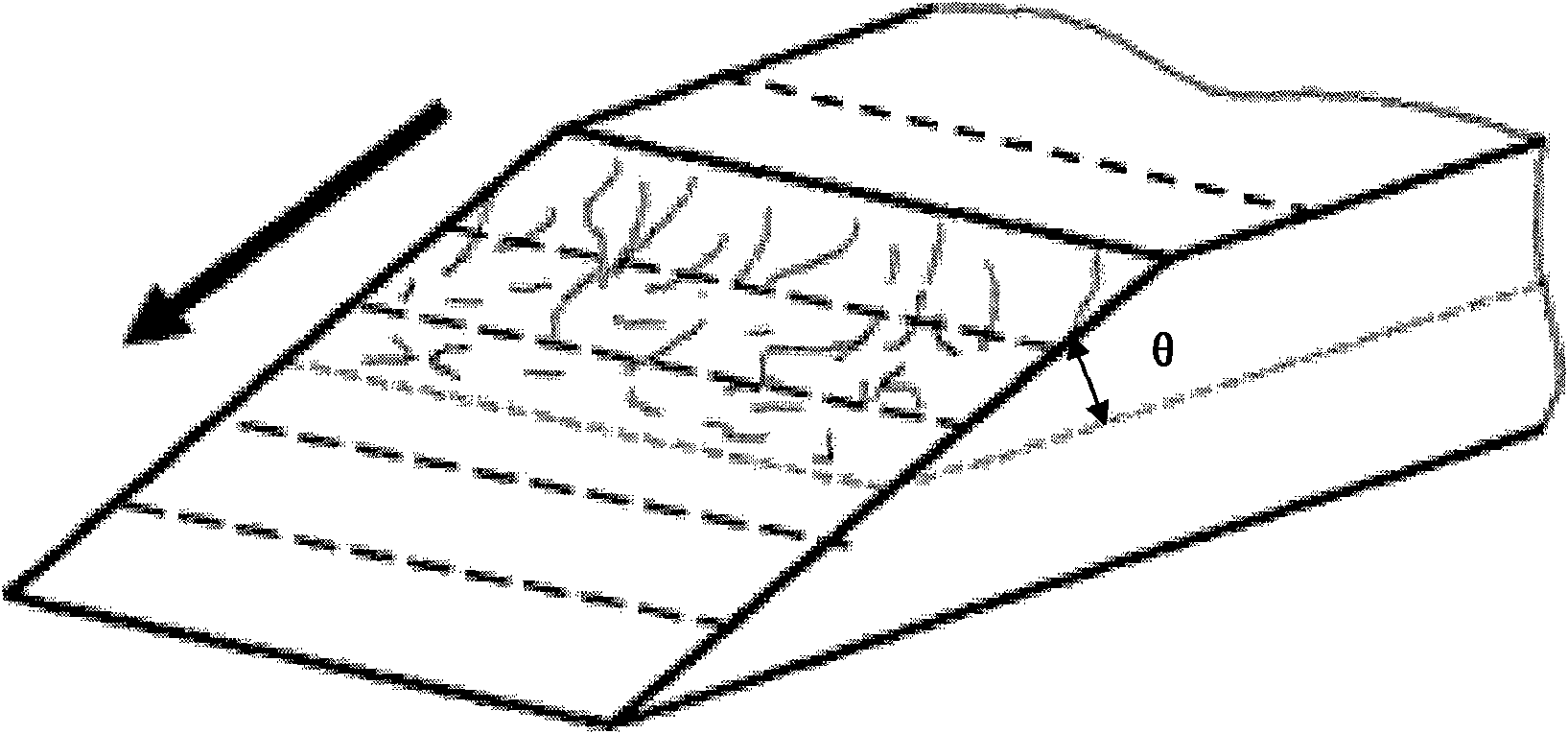

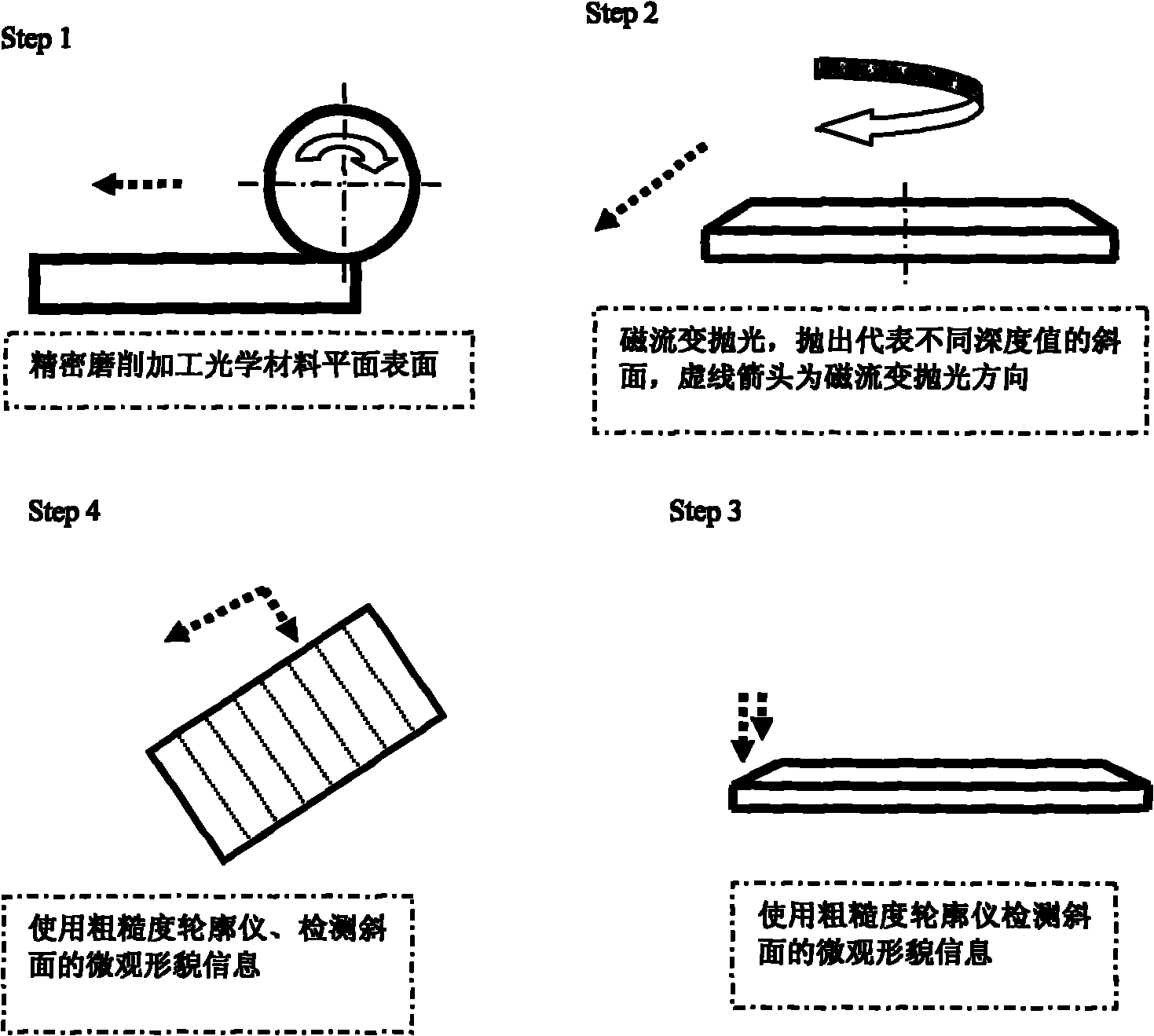

[0032] figure 2 , image 3 A processing example of an optical glass flat sample is shown. Measurement of the subsurface damage layer thickness of a K9 optical glass flat sample: in image 3 Step1 Subsurface damage detection is performed on the optical surface after W20 abrasive grinding for 20 minutes: image 3 As shown in Step2, the magneto-rheological polishing process is used to process a tiny slope with an inclination angle of θ=6' ( figure 2 ), along the direction of magnetorheological polishing indicated by the arrow, the profile information at different depths from the original plane can be reflected on the slope. Use HF acid corrosion reagent to treat the slope after magnetorheological polishing, clean the surface and further expose and enlarge the cracks on the slope. Use the roughness profiler to scan from the dotted line near the start boundary of the slope ( figure 2 , image 3 Step3), feed along the slope along the direction of the arrow according to the ...

Embodiment 2

[0035] Such as Figure 6 As shown, a specific measurement example of the thickness of the subsurface damage layer of an optical ceramic spherical mirror, in Figure 6 Subsurface damage detection is performed on the optical surface after W40 abrasive grinding for 20 minutes in Step 1: Figure 6 Shown in Step 2: using the magnetorheological polishing process to throw a detection circular plane on a spherical sample with a radius of curvature R, and its horizontal radius is r. The cutting plane and the original spherical surface form a spherical cap ( Figure 6 Step2), the circumference of the plane is shallower than the original surface, and the center of the circle is deeper than the original surface. Use corrosive chemical reagents to treat the cut plane to enlarge the exposure of subsurface cracks on the cut plane; Figure 6 In Step3 and Step4: Use the white light interferometer to scan the circular plane from the circumference of the point P 1 (X 1 , Y 1 ,Z 1 ) along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com