Biomimetic tissue culture room

A technology of tissue culture room and culture room, which is applied in the field of biological tissue engineering preparation devices, can solve the problems of reduced nutrient exchange surface, limited promotion of tissue engineering tissue in vitro development, and inability to adapt to clinical applications, so as to prevent pollution and promote Effects of array distribution and extracellular matrix secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

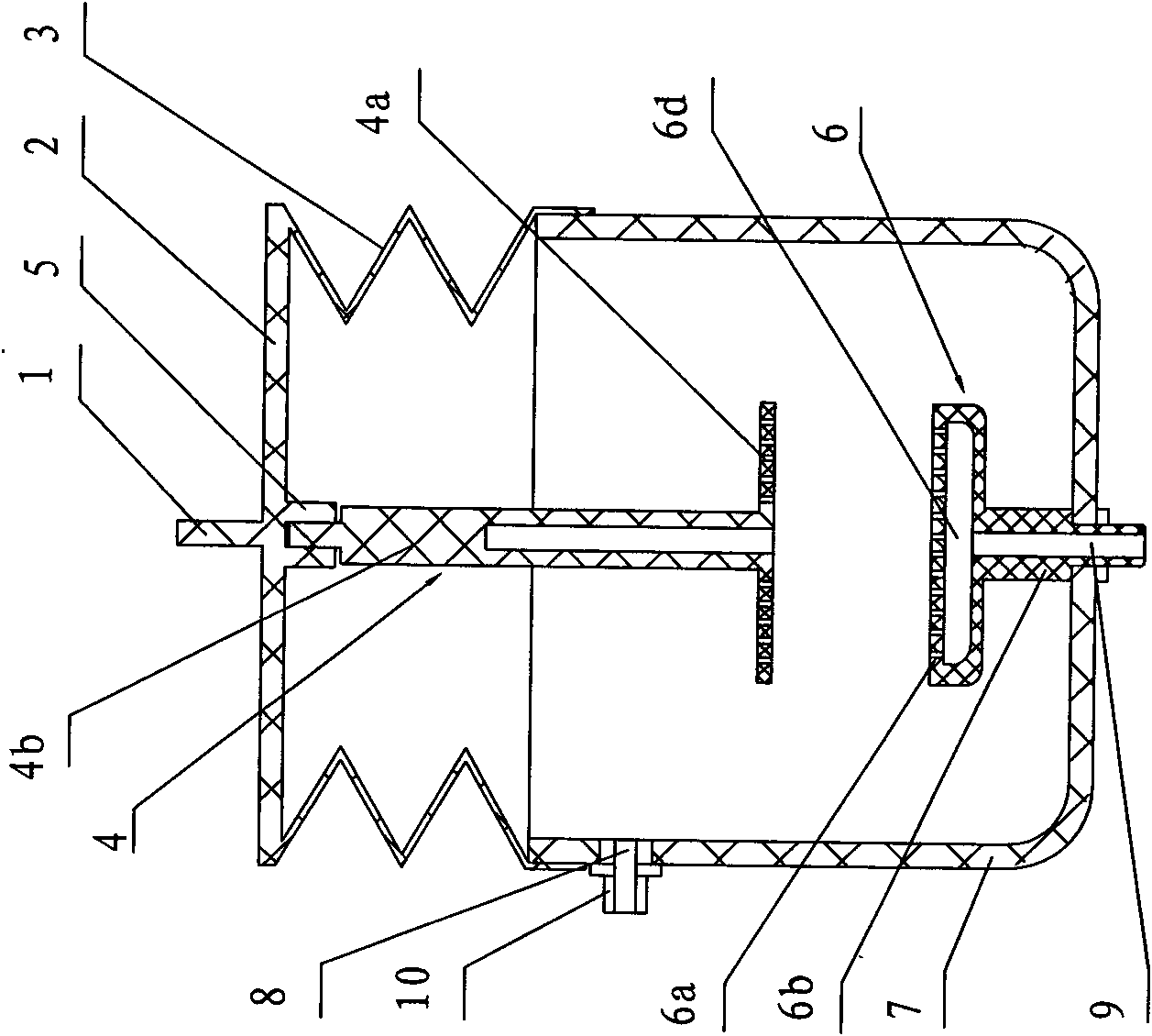

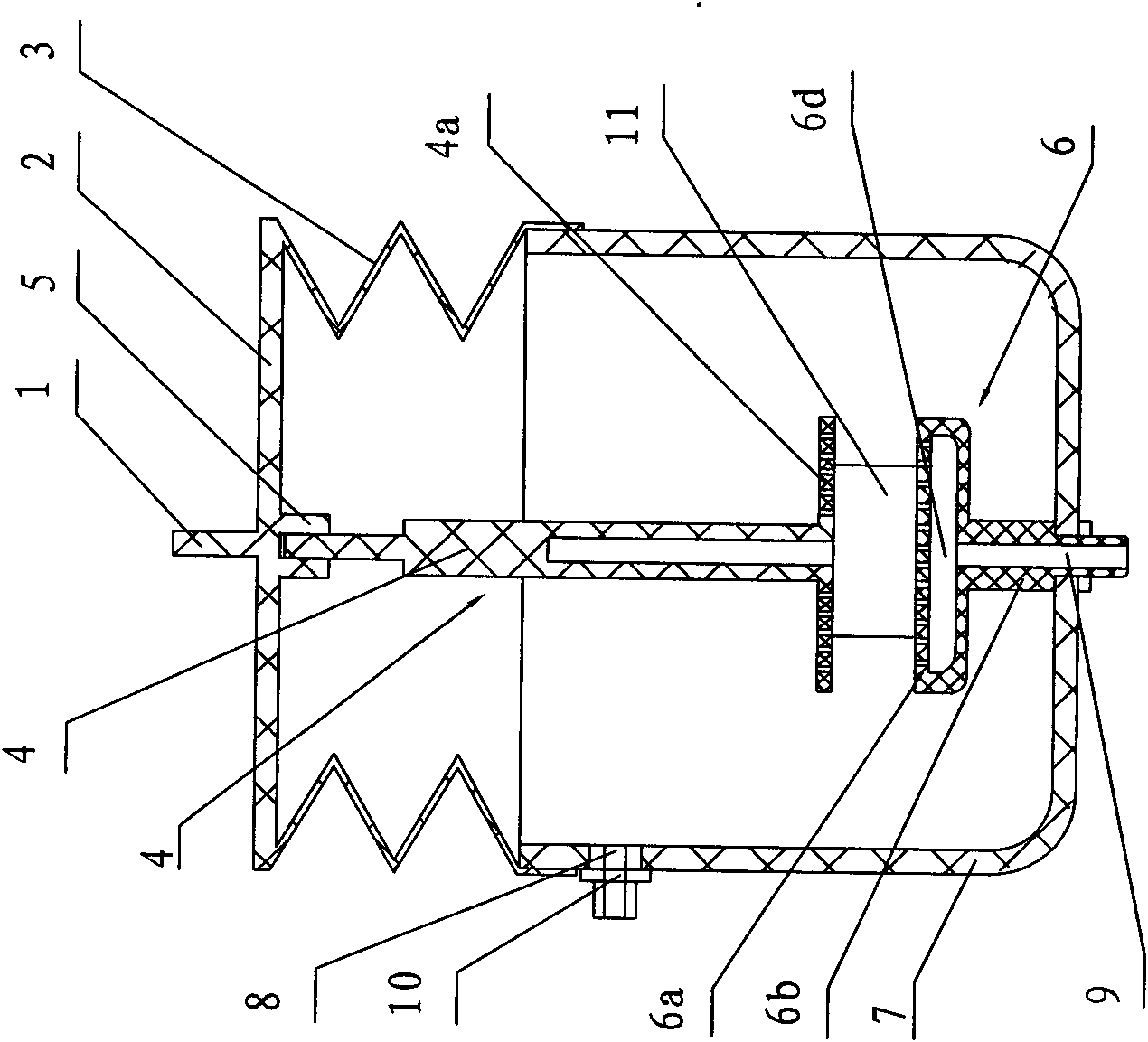

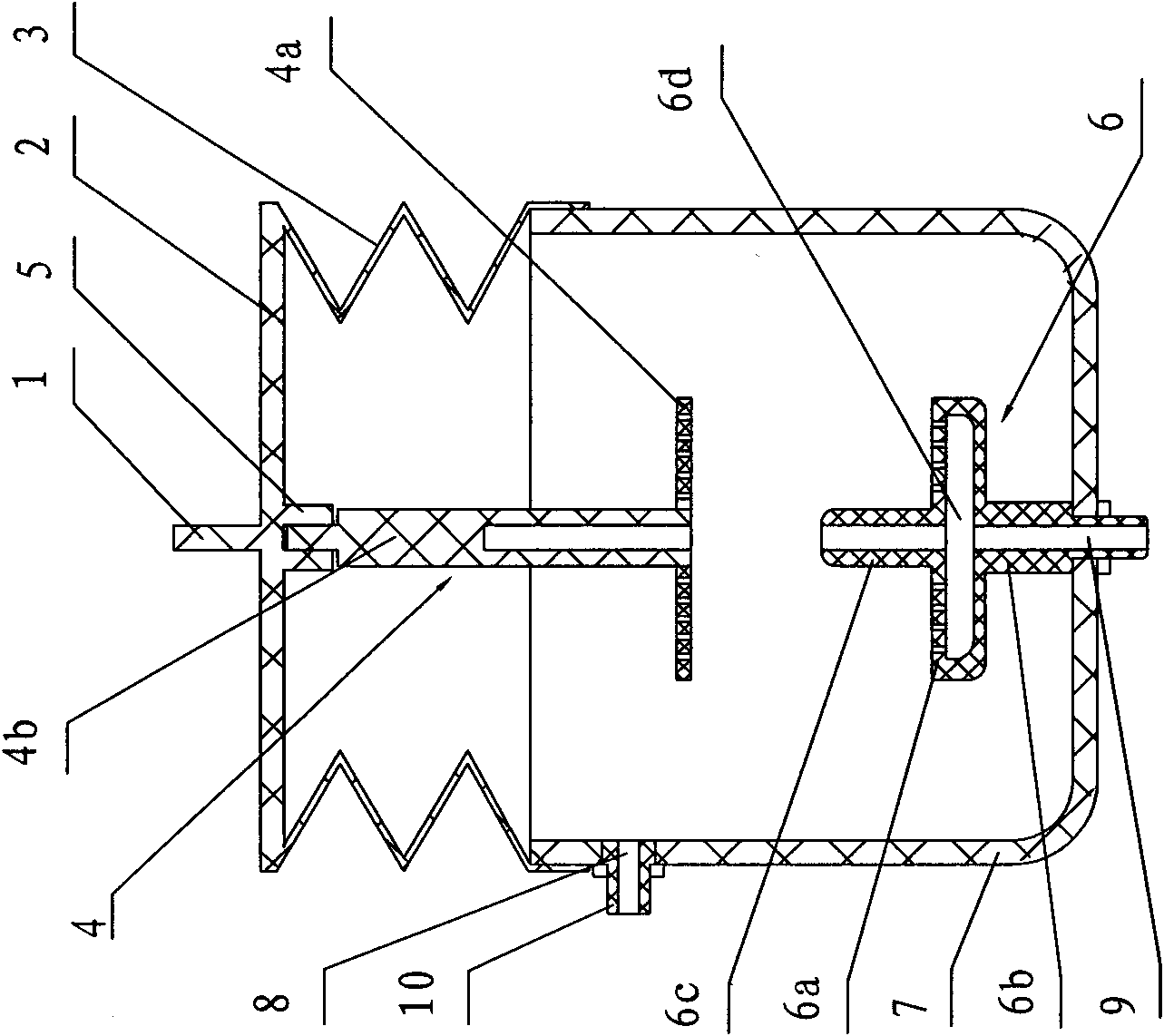

[0025] see figure 1 , figure 2 , the present embodiment is a bionic tissue culture room for constructing flaky cartilage tissue, the culture room includes a lower container 7 and an upper cover 2, and the lower container 7 and an upper cover 2 made of medical plastics are used in the culture room, and the upper The cover 2 is integrally formed with a stretchable folding edge 3, and the stretchable folding edge 3 of the upper cover 2 is connected with the lower container 7 to form a sealed cultivation chamber. The connection between the upper cover 2 and the lower container 7 can be screwed tightly, or an interference fit can be used, so that the upper cover 2 is tightly connected with the lower container 7 and forms a seal. The lower container 7 is respectively provided with an output hole 8 and an input hole 9 of the culture solution, the output hole 8 is positioned at the upper part of the side wall of the lower container 7, and the output hole 8 is provided with a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com