Martensite abrasion-resistant steel with high strength and production produce thereof

A production process, martensite technology, applied in the field of iron-based alloys and its production process, can solve the problems of increasing production costs, etc., and achieve the effect of improving strength and wear resistance, good wear resistance, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

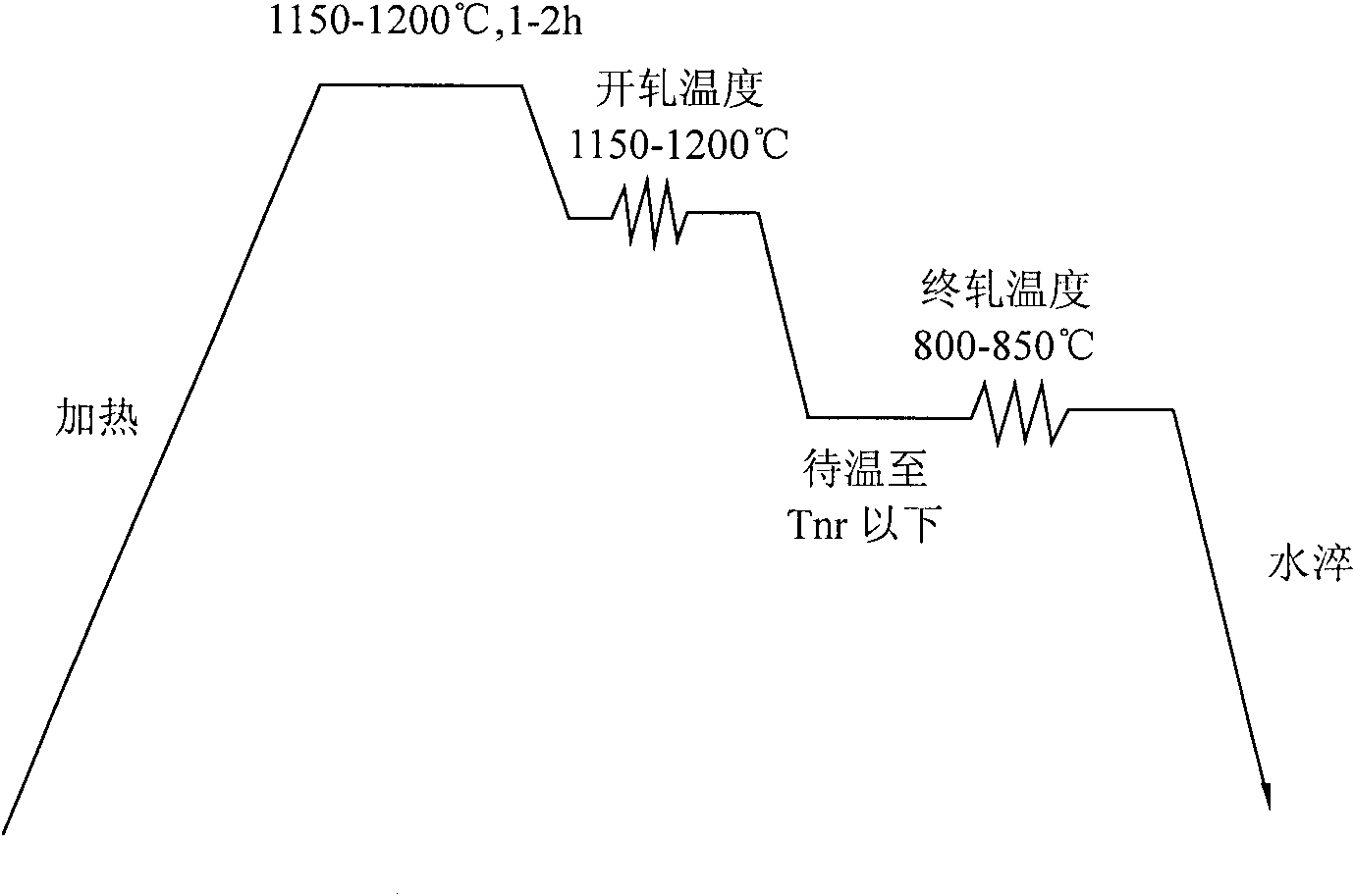

Method used

Image

Examples

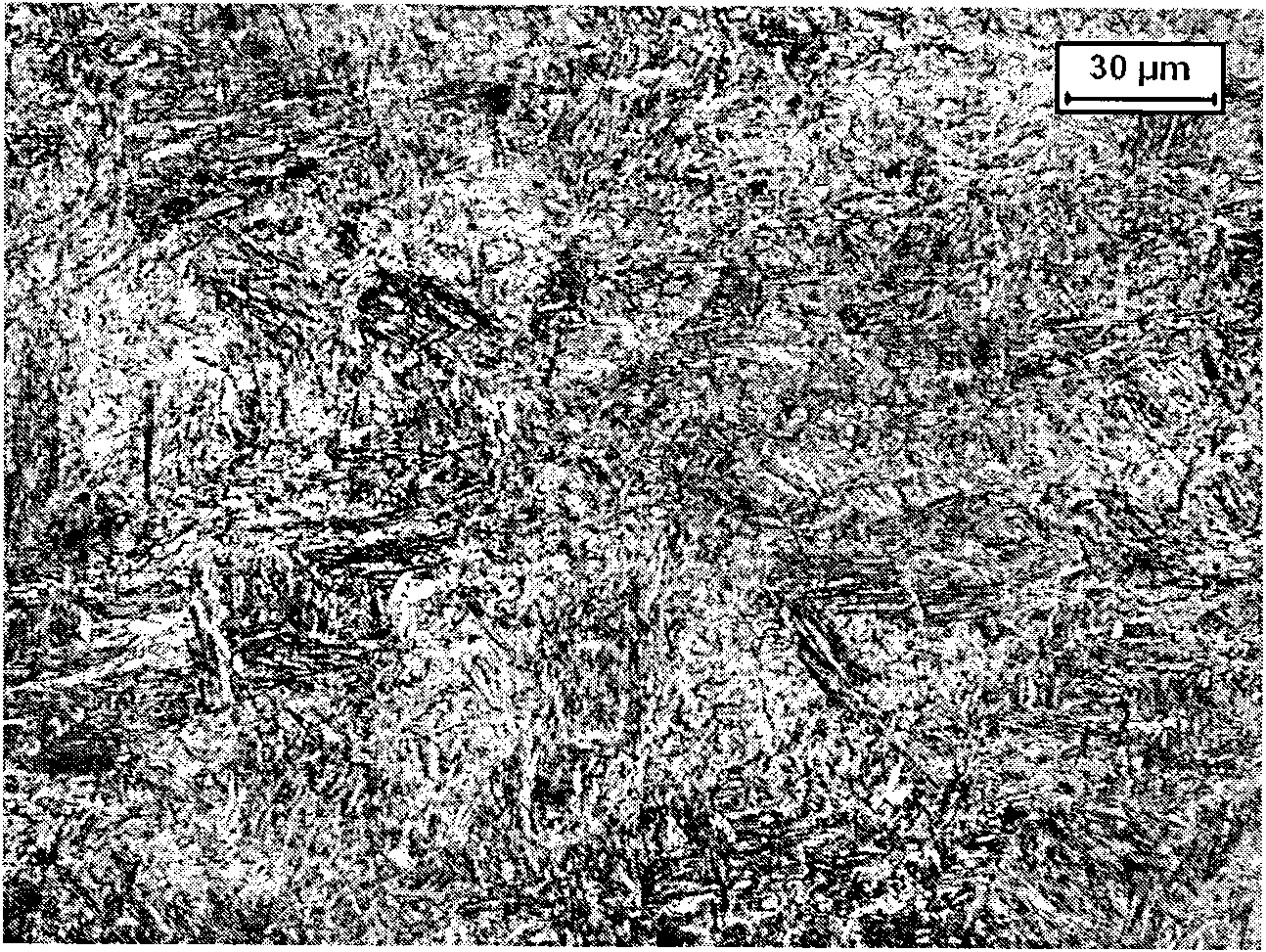

Embodiment Construction

[0028] The steel slab with the composition shown in Table 1 was obtained from steelmaking, and processed according to the rolling process in Table 2 to obtain the wear-resistant steel plate of the present invention with a thickness of 15 mm. The performance parameters of the steel plate are shown in Table 3.

[0029] Table 1 billet composition

[0030]

[0031] Table 2 Rolling process

[0032]

[0033] Table 3 performance parameters of steel plate

[0034] serial number

Yield strength MPa

Tensile strength MPa

Elongation%

-20℃ Transverse V-shaped impact energy

Example 1

1160

1450

12.8

32

Example 2

1190

1495

12.3

33

[0035] Example 3

1238

1585

11.0

35

Example 4

1320

1665

11.8

36

Example 5

1395

1743

11.5

38

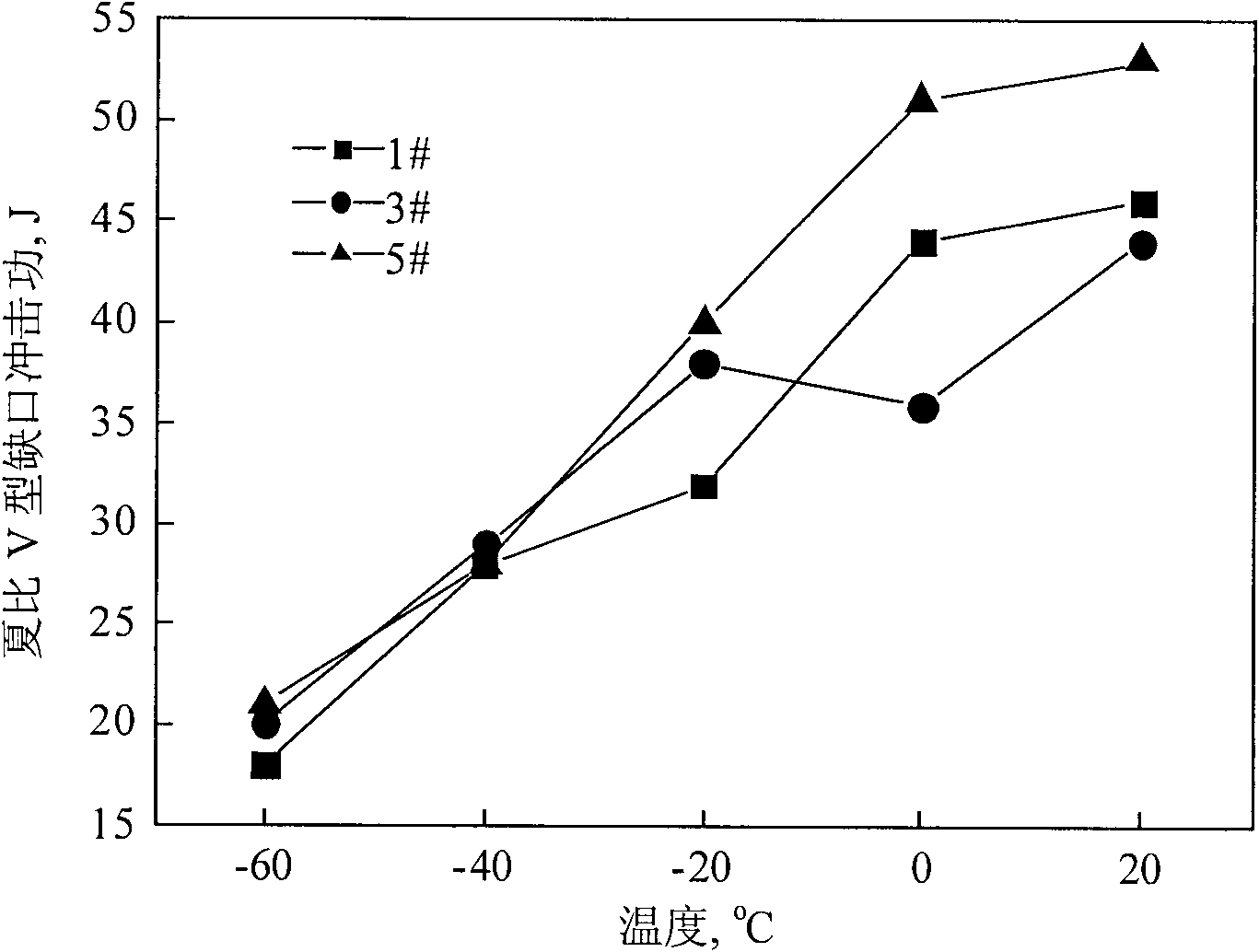

[0036]As can be seen from Table 1, Table 2 and Table 3, for Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com