Cooling water supply method and system for equipment

A water supply system and cooling water technology, which is applied in lighting and heating equipment, fixed plate conduit components, heat exchanger types, etc. The effect of facilitating equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

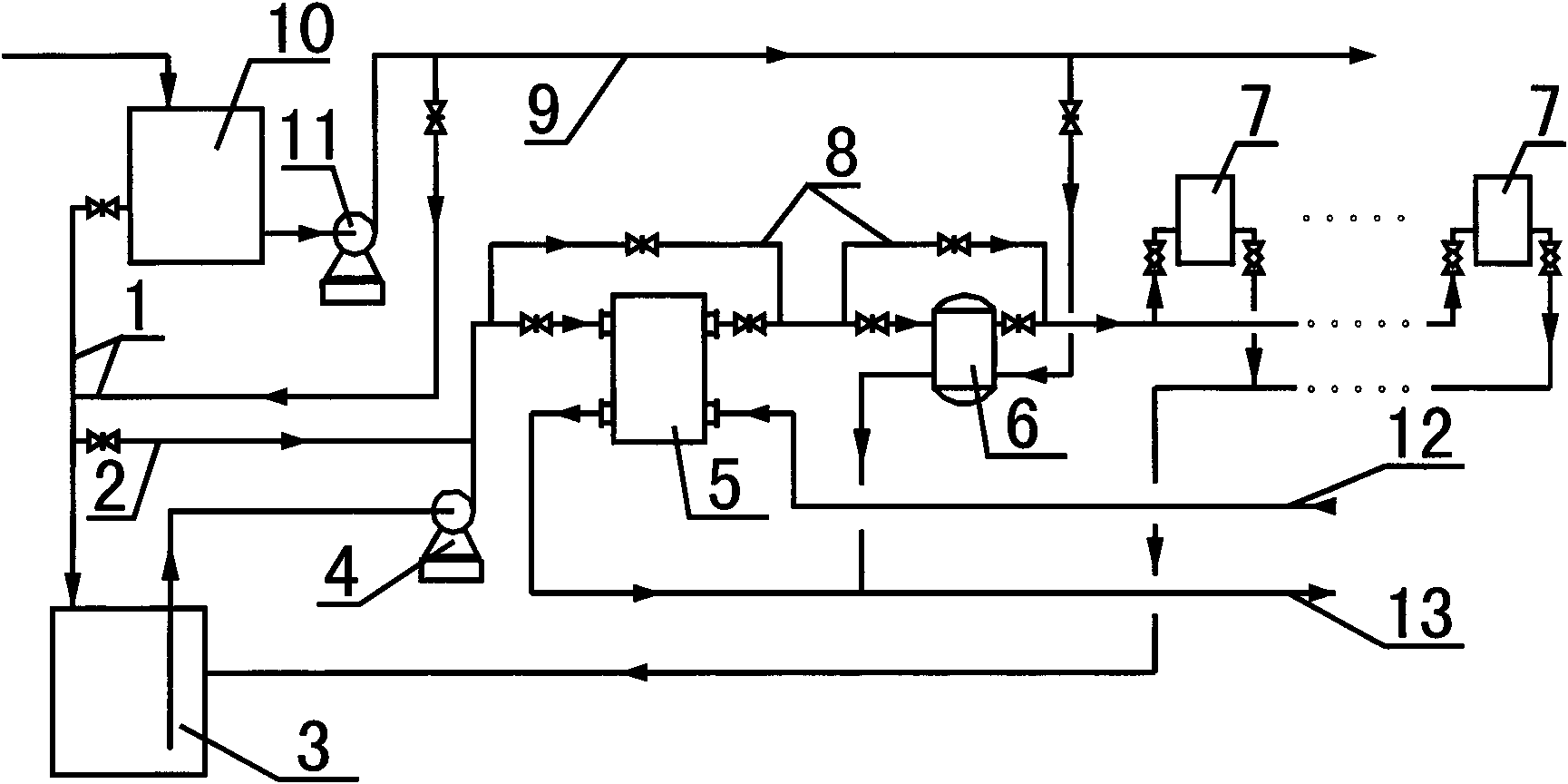

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0026] The cooling water supply method for equipment of the present invention comprises the following process steps: the qualified condensed water from the evaporation of mother liquor or pressure boiling and dissolution process is sent to the qualified condensed water tank and then sent to the soft water tank through the water injection pipe, and the qualified condensed water is directly passed through the injector The water pipe is sent to the soft water tank or the qualified condensate sent to the thermal power plant is sent to the soft water tank through the water injection pipe, and the qualified condensed water sent to the thermal power plant is sent to the thermal power plant through the qualified condensate pump; the soft water in the soft water tank is sent to the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com