A thermal decomposition treatment system of flammable waste and method for treating the waste using the system

一种处理系统、热分解的技术,应用在可燃性废弃物热分解处理系统及使用该系统的废弃物处理领域,能够解决空气污染、作业效率低、炉收缩变形等问题,达到能效优越、工程效率极大化、防止大气污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

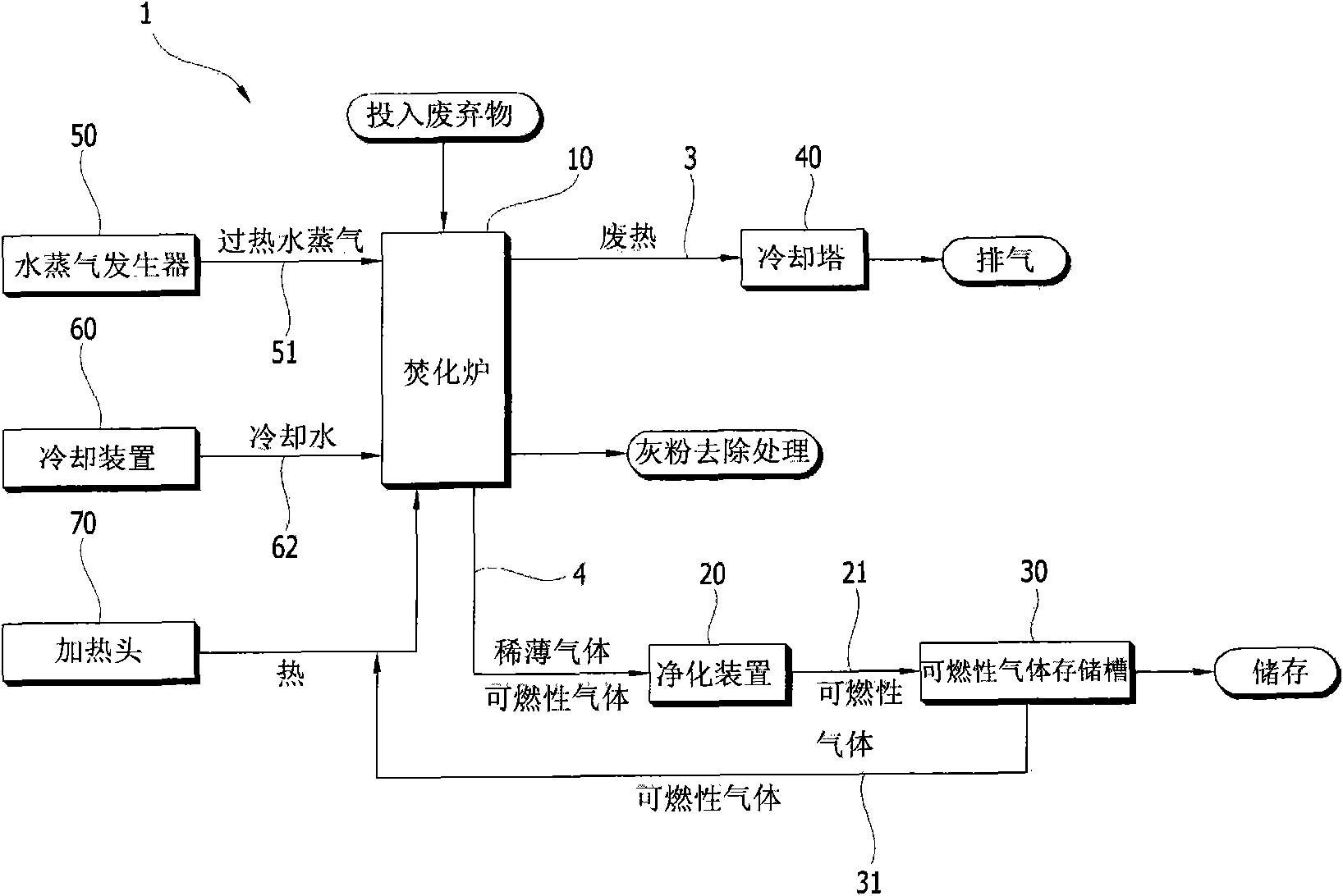

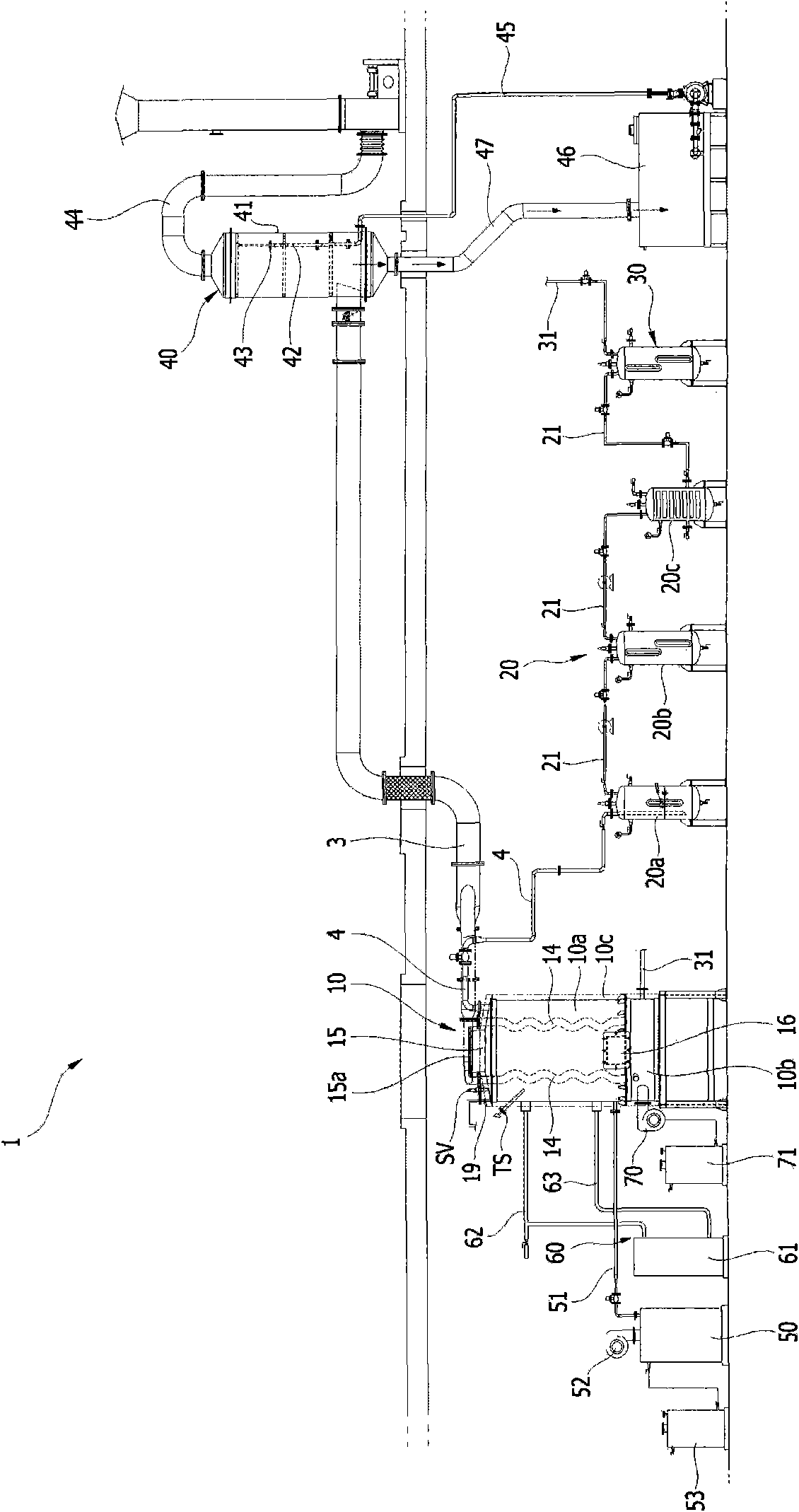

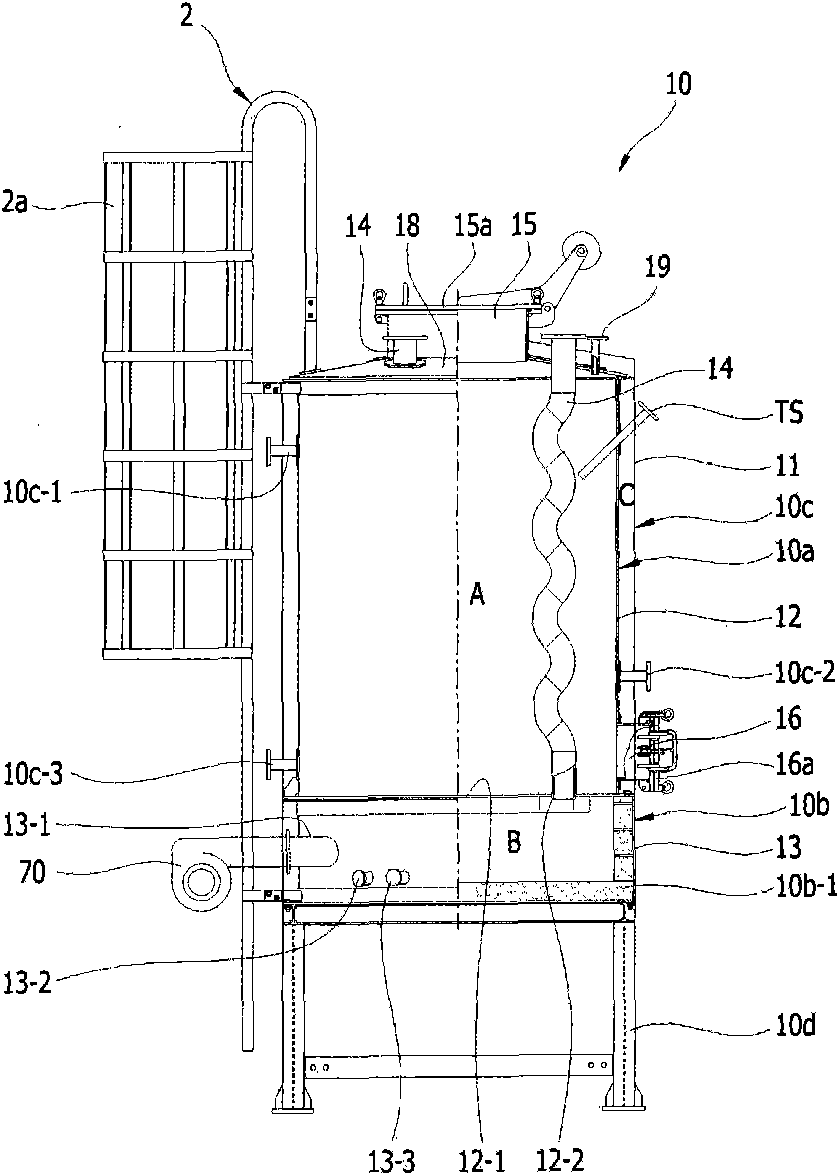

[0042] Preferred embodiments of the combustible waste thermal decomposition treatment system and the waste treatment method using the system according to the present invention will be described in detail below with reference to the accompanying drawings.

[0043] figure 1 To represent the brief treatment process diagram of the combustible waste pyrolysis treatment system of the present invention, figure 2 To represent the system structure diagram of the combustible waste pyrolysis treatment system of the present invention, image 3 , Figure 4 It is a structural diagram showing an incinerator suitable for the combustible waste pyrolysis treatment system of the present invention, and, Figure 5 , Figure 6 to indicate that it applies to image 3 , Figure 4 Front view of the heating tubes and pressure gauges and vacuum gauges.

[0044] As shown in the figure, the combustible waste thermal decomposition treatment system 1 according to the present invention mainly includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com