Method of manufacturing an ultra-microelectrode

An ultra-micro electrode and manufacturing method technology, which is applied in the field of probes for scanning electrochemical microscopes, can solve the problems of reduced sensitivity, inaccurate measurement results, broken electrode wires, etc., and achieves widening application fields, improving sensitivity, and improving resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

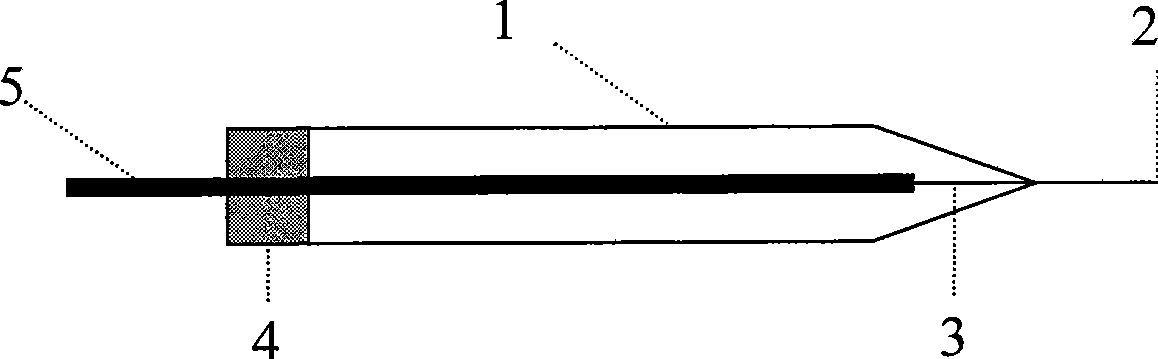

[0030] Take the platinum microelectrode as an example: first, draw a clean glass capillary 1 with an inner diameter of 1 mm, and draw one end of it with a microtube drawing instrument (Chengdu Instrument Factory, WD-1, Chengdu) under a heating index of 750 degrees. into a tip with an inner diameter of approximately 80 µm. Then, the platinum wire with a diameter of 25 μm and the copper wire 5 with a diameter of 0.5 mm after cleaning with acetone and secondary water were bonded together with silver powder conductive adhesive, and placed in an oven at 150° C. for 0.5 h. Then it is solidified into platinum and copper wires, and one end of the platinum wire is inserted into the pointed capillary, and the platinum wire is exposed to the tip of the capillary by 1cm. Place the tip of the capillary containing platinum wire at the outer flame of an alcohol lamp and burn for 0.3 seconds. Repeated 3 times, the capillary tip melted and the platinum wire was sealed in it. The other end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com