Polypropylene copolymer

A technology of polypropylene copolymer and propylene, which is applied in the field of propylene copolymer and its preparation, and can solve the problems of unsatisfactory reduction of melting point of comonomers, poor impact strength, processability, and damage to transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

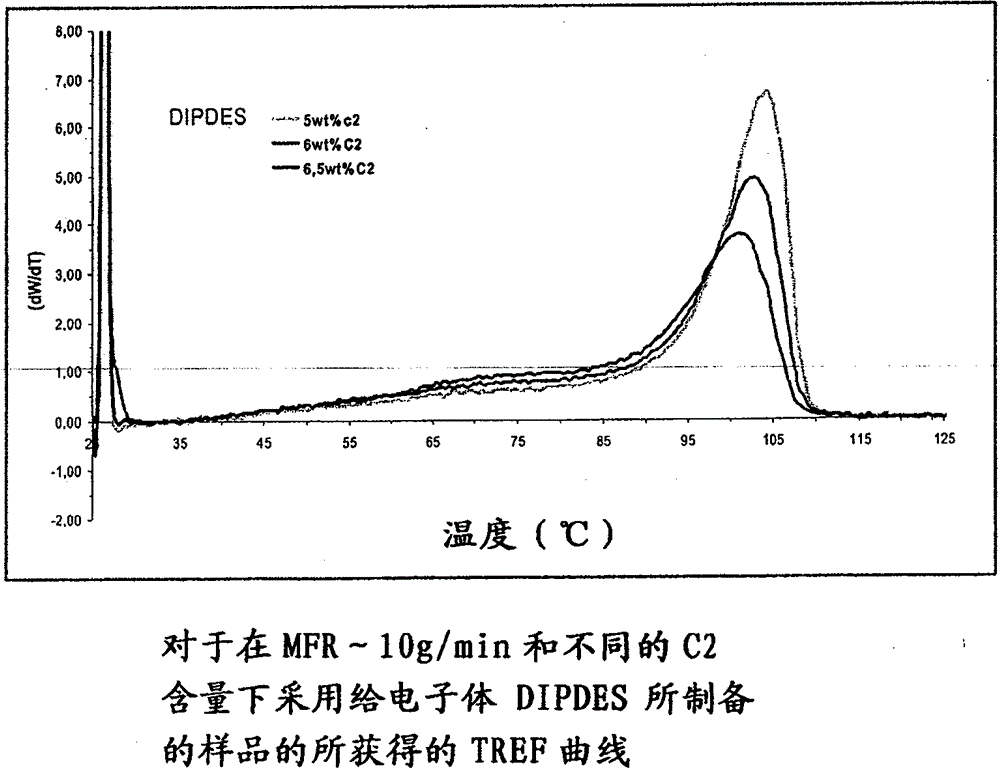

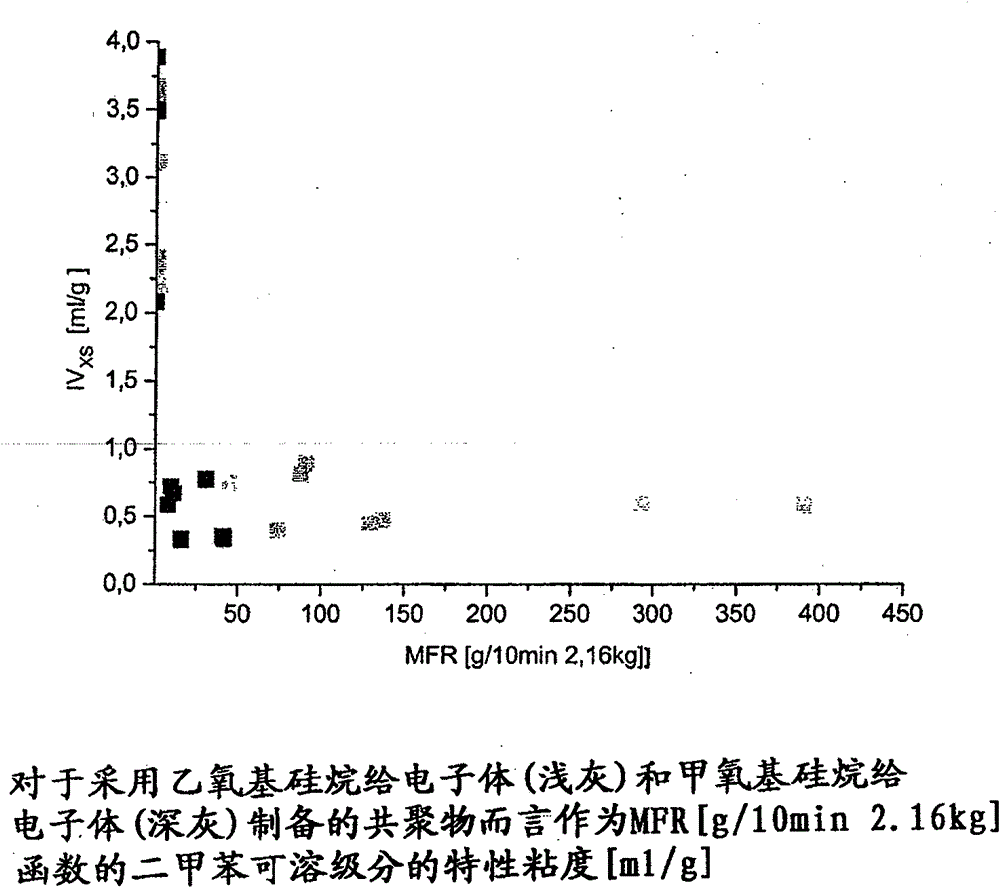

[0537] Example 1: DIPDES; MFR 10 g / 10 min; C2 content 6.5% by weight (invention)

[0538] The propylene polymers used in the present invention are prepared according to the following procedure:

[0539] Raw materials:

[0540] - Hexane dried over molecular sieves (3 / 10A)

[0541] -TEAL: 93%, from Sigma-Aldrich

[0542] - electron donor: diisopropyldiethoxysilane from Wacker Chemie (the preparation of this electron donor is described in DE 38 21 483 A1)

[0543] -N 2 : Supplier AGA, quality 5.0; with catalyst BASF R0311, catalyst G132 (CuO / ZnO / C), molecular sieve (3 / 10A) and P 2 o 5 Purify.

[0544] - Hydrogen: Supplier AGA, quality 6.0

[0545] - Propylene: Supplier Borealis

[0546] - Vinyl: Supplier Air Liquide 3.5

[0547] - Catalyst Polytrack 8502 is commercially available from Grace.

[0548] -Sandos tab P-EPQ is an antioxidant and commercially available from Clariant

[0549] -Millad 3988 is a nucleating agent and is commercially available from Milliken

[...

Embodiment 2

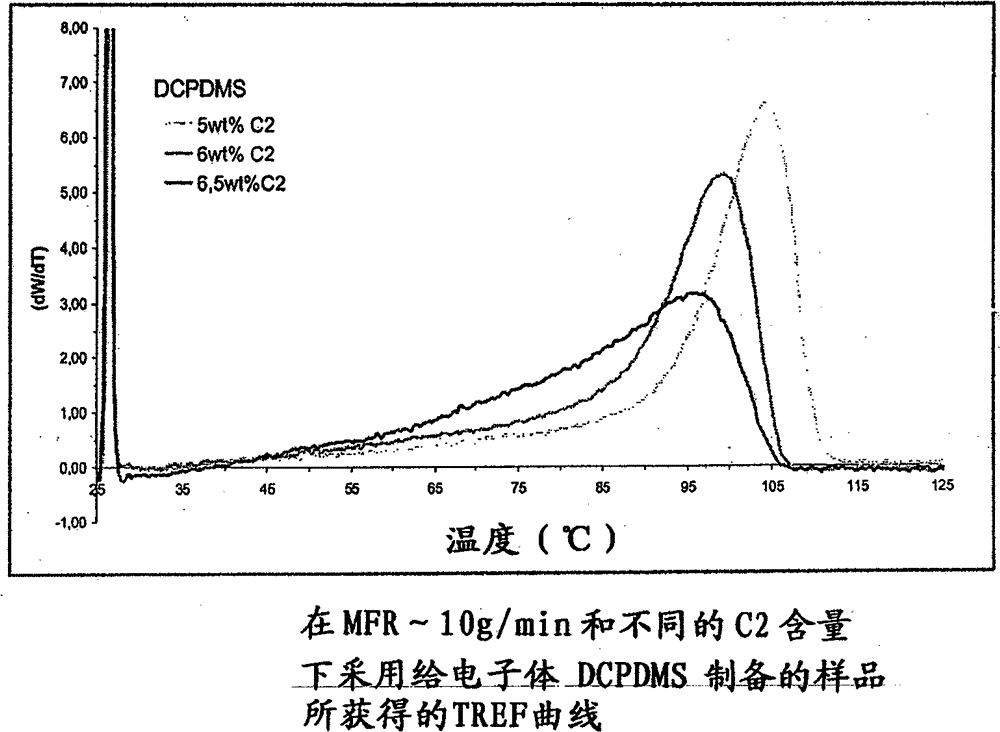

[0560] Embodiment 2: DCPDMS; MFR 9 grams / 10 minutes; C2 content 6.5% by weight (the present invention)

[0561] The propylene polymers used in the present invention are prepared according to the following procedure:

[0562] Raw materials:

[0563] - Hexane dried over molecular sieves (3 / 10A)

[0564] -TEAL: 93%, from Sigma-Aldrich

[0565] - electron donor: diisopropyldiethoxysilane from Wacker Chemie (the preparation of this electron donor is described in DE 38 21 483 A1)

[0566] -N 2 : Supplier AGA, quality 5.0; with catalyst BASF R0311, catalyst G132 (CuO / ZnO / C), molecular sieve (3 / 10A) and P 2 o 5 Purify.

[0567] - Hydrogen: Supplier AGA, quality 6.0

[0568] - Propylene: Supplier Borealis

[0569] - Vinyl: Supplier Air Liquide 3.5

[0570] - Catalyst Polytrack 8502 is commercially available from Grace.

[0571] -Sandostab P-EPQ is an antioxidant and commercially available from Clariant

[0572] -Millad 3988 is a nucleating agent and is commercially availab...

Embodiment 3

[0583] Example 3: DIPDES; MFR 11 g / 10 min; C2 content 4.5% by weight (invention)

[0584] The propylene polymers used in the present invention are prepared according to the following procedure:

[0585] Raw materials:

[0586] - Hexane dried over molecular sieves (3 / 10A)

[0587] -TEAL: 93%, from Sigma-Aldrich

[0588] - electron donor: diisopropyldiethoxysilane from Wacker Chemie (the preparation of this electron donor is described in DE 38 21 483 A1)

[0589] -N 2 : Supplier AGA, quality 5.0; with catalyst BASF R0311, catalyst G132 (CuO / ZnO / C), molecular sieve (3 / 10A) and P 2 o 5 Purify.

[0590] - Hydrogen: Supplier AGA, quality 6.0

[0591] - Propylene: Supplier Borealis

[0592] - Vinyl: Supplier Air Liquide 3.5

[0593] - Catalyst Polytrack 8502 is commercially available from Grace.

[0594] -Sandostab P-EPQ is an antioxidant and commercially available from Clariant

[0595] -Millad 3988 is a nucleating agent and is commercially available from Milliken

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com