Method of preparing catalytic material for indium hydroxide thin film with controllable shape and thickness

A technology of indium hydroxide and catalytic materials, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., which can solve secondary pollution of semiconductor materials, low catalytic efficiency, production Complicated methods and other issues, to achieve the effect of mild conditions, good catalytic activity, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

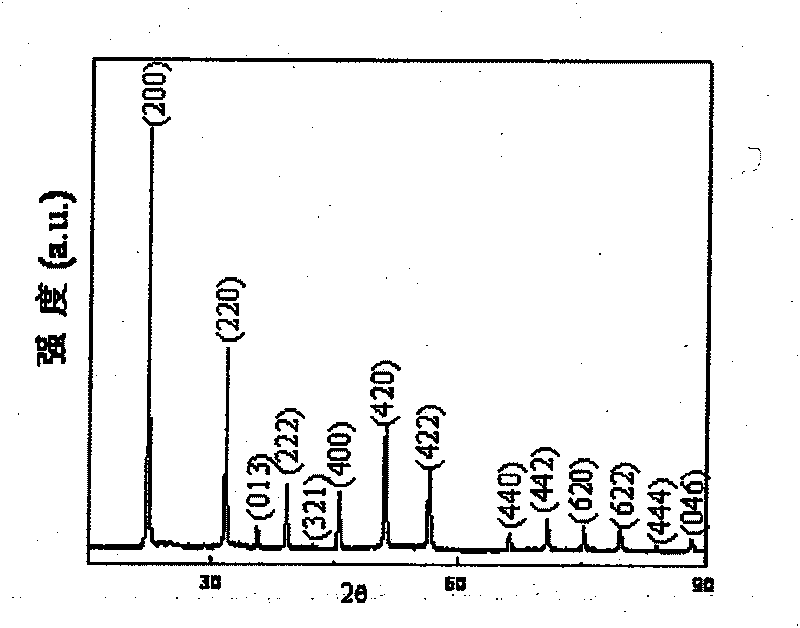

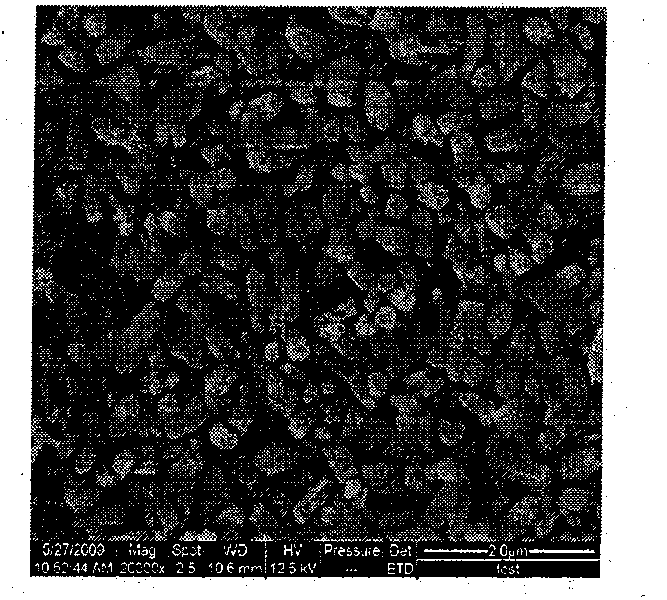

[0008] Specific Embodiment 1: In this embodiment, the indium hydroxide thin film catalytic material with controllable morphology and thickness is prepared by the following method: 0.5-8g of urea, 0.5-2g of indium nitrate and 100-150mL of water are uniformly mixed and placed in the reaction Then put the glass plate into the reactor, then put the reactor into the oil bath for reflux reaction for 12~26h, control the temperature of the oil bath reflux device to 60~100℃, that is to realize the indium hydroxide film Preparation of catalytic materials.

[0009] This embodiment can adjust the OH released by urea in the solution by controlling the amount of urea - Concentration, in realizing the control of the shape and thickness of the film, the thickness range of the indium hydroxide film produced in this embodiment is 4-30 μm, and at the same time, the shape and thickness of the indium hydroxide film can also be controlled by controlling the reflow time, The morphology of the thin ...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that 1.7-1.9 g of urea, 1.4-1.6 g of indium nitrate and 120-145 mL of water are evenly mixed and placed in a container. Other steps and parameters are the same as those in Embodiment 1.

[0011] The thickness of the indium hydroxide thin film manufactured in this embodiment is 0.8-42 mm.

specific Embodiment approach 3

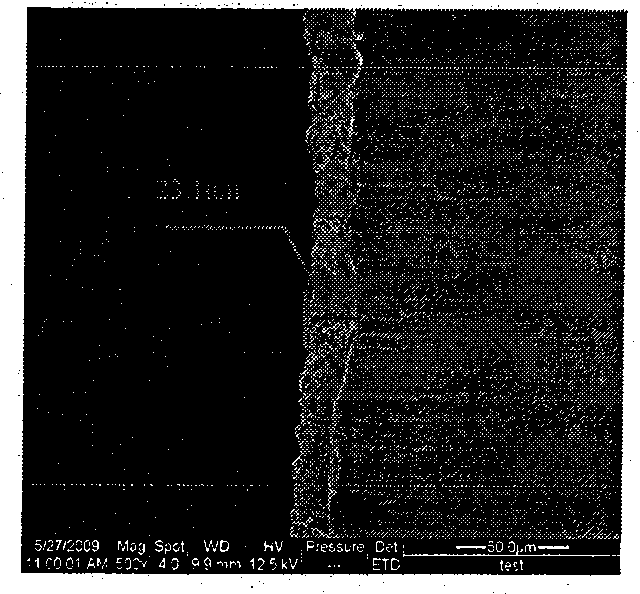

[0012] Embodiment 3: This embodiment is different from Embodiment 1 in that 1.8018 g of urea, 1.5278 g of indium nitrate and 140 mL of water are uniformly mixed and placed in a container. Other steps and parameters are the same as those in Embodiment 1.

[0013] The thickness of the indium hydroxide film produced in this embodiment is 19.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com