Pulverized coal dispersing agent and active water fracturing fluid for fracturing of coal bed gas well

A technology for coalbed methane wells and dispersants, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining production capacity, increased cost of coalbed methane well mining and development, and high Poisson's ratio, reducing the number of pump inspections, The effect of avoiding coal dust aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

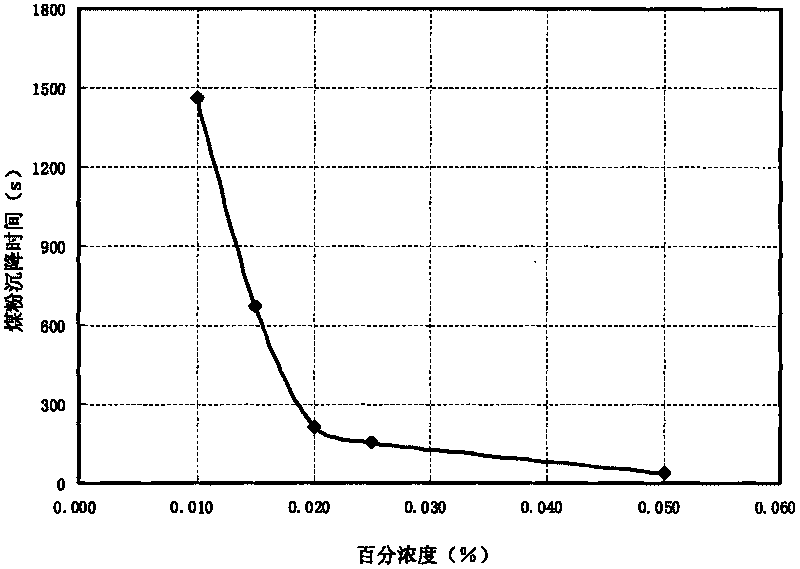

[0025] Mix octylphenol polyoxyethylene (10) ether (abbreviated as OP-10), 12-alkyl-3-methylammonium chloride, and ethanol in a ratio (mass ratio) of 2:1:7 to prepare a clarified Transparent coal powder dispersant stock solution. Add 0.15 parts by mass of coal powder dispersant stock solution and 1.0 to 1.5 parts by mass of potassium chloride into 98.85 to 98.35 parts by mass of water, and mix evenly to form a clear and transparent coal powder dispersant active water fracturing fluid, coal powder The stock solution of the dispersant accounts for 0.15% of the total mass of the final fracturing fluid, and the potassium chloride accounts for 1.0-1.5% of the total mass of the final fracturing fluid. The prepared fracturing fluid can be used in the fracturing of coalbed methane wells with low pulverized coal content. During fracturing, it can be used as a pre-fluid or a sand-carrying fluid alone, or it can be used in the whole process. According to the pre-fluid, sand-carrying fluid...

Embodiment 2

[0027] Mix octylphenol polyoxyethylene (10) ether (abbreviated as OP-10), 12-alkyl-3-methylammonium chloride, and diethyl ether in a ratio (mass ratio) of 2:1:7 to prepare a clarified Transparent coal powder dispersant stock solution. Add 0.15 parts by mass of coal powder dispersant stock solution and 1.0 to 1.5 parts by mass of potassium chloride into 98.85 to 98.35 parts by mass of water, and mix evenly to form a clear and transparent coal powder dispersant active water fracturing fluid, coal powder The stock solution of the dispersant accounts for 0.15% of the total mass of the final fracturing fluid, and the potassium chloride accounts for 1.0-1.5% of the total mass of the final fracturing fluid. The prepared fracturing fluid can be used in the fracturing of coalbed methane wells with low pulverized coal content. During fracturing, it can be used as a pre-fluid or a sand-carrying fluid alone, or it can be used in the whole process. According to the pre-fluid, sand-carrying...

Embodiment 3

[0029] For coalbed methane well fracturing with higher pulverized coal content, the consumption of the coal powder dispersant stock solution in the fracturing fluid of embodiment 1 or embodiment 2 can be increased from 0.15 mass parts to 0.20 mass parts, simultaneously in the fracturing fluid The adaptability of the water used is reduced, and the amount of potassium chloride remains unchanged, that is, the stock solution of coal powder dispersant in the fracturing fluid is increased from 0.15% to 0.20% of the total mass of the fracturing fluid, and the effect will be better; if the reservoir The content of medium pulverized coal is very high, and the consumption of the coal powder dispersant stock solution in the fracturing fluid of Example 1 can also be increased to 0.25 parts by mass, and the adaptability of the amount of water used in the fracturing fluid is reduced simultaneously, and the amount of potassium chloride No change, that is, the stock solution of coal powder dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com