Device and method for controlling heating temperature of movable type single-particle testing device

A heating temperature and control device technology, which is applied in temperature control, non-electric variable control, measuring devices, etc., can solve the problems of difficult control of semiconductor device heating temperature, influence of single particle test effect, difficult temperature control, etc., and achieves simple structure, Fast heating, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

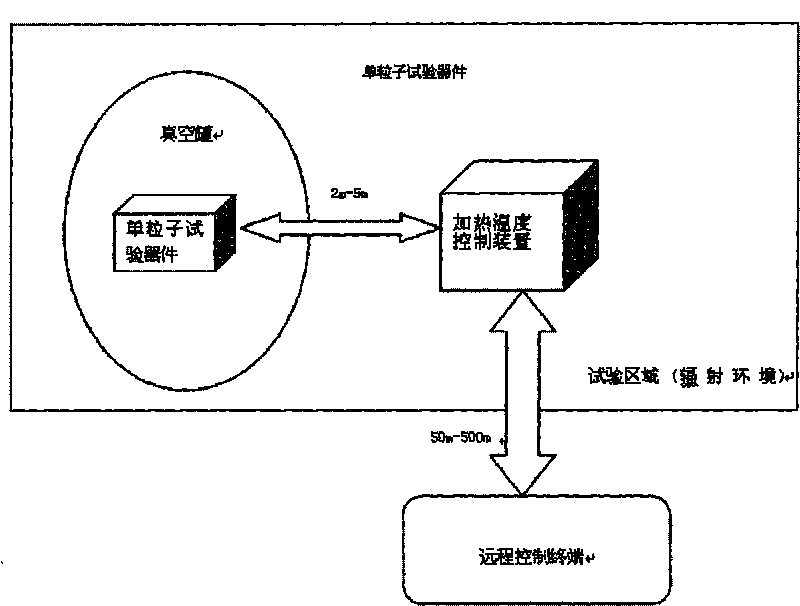

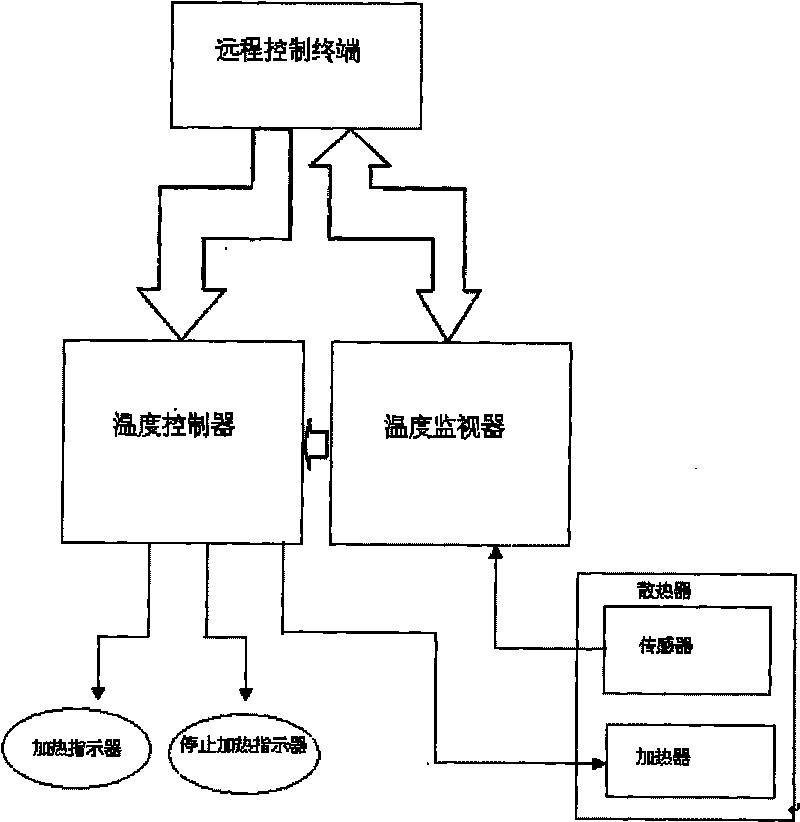

[0041] Such as figure 2Shown is the structural diagram of the heating temperature control device of the single particle test device of the present invention, it can be seen from the figure that the heating temperature control device includes a temperature controller, a temperature monitor, a heater, a sensor, a radiator, a fixture, a heating indicator light, and a heating stop indicator light and a remote control terminal, wherein the remote control terminal is connected to the temperature controller and the temperature monitor, the temperature controller and the temperature monitor are connected to each other, and the temperature controller is connected to the heater, the heating indicator light and the heating stop indicator light, and the temperature monitor is connected to the sensor , wherein the remote control terminal transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com