Fluorescent powder for LED

A technology of light-emitting diodes and phosphors, applied in the fields of phosphor materials and phosphate-based phosphors, can solve the problems of shortage of phosphors, poor color reproduction of white LEDs, and lack of red light components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

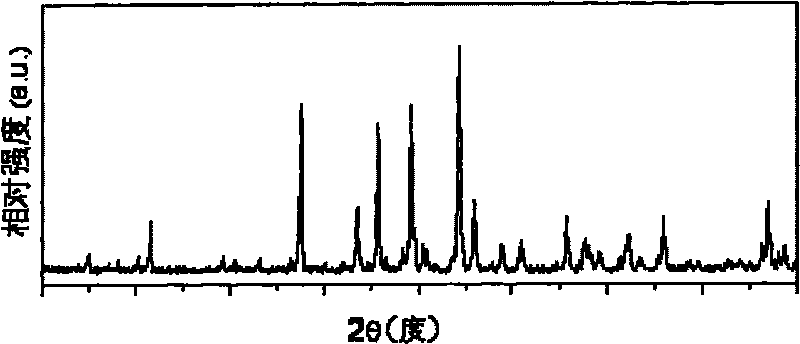

Image

Examples

preparation example Construction

[0012] The preparation method of the fluorescent powder that the light-emitting diode provided by the invention comprises the following steps:

[0013] ① Weigh the raw materials according to a certain stoichiometric ratio. The raw materials of alkaline earth metals can be selected from carbonates, basic carbonates, nitrates, etc.; the raw materials of phosphate can be selected from NH 4 h 2 PO 4 , can also choose SrHPO 4 etc. to provide alkaline earth metal ions and phosphate radicals at the same time; the raw materials of europium ions can use corresponding oxides, nitrates, oxalates, etc., and the raw materials of manganese ions can use their carbonates.

[0014] ② Add appropriate amount of ethanol to various raw material mixtures and stir to make them fully mixed, and then dry;

[0015] ③ Fully grind the dried raw materials again, then move them to a corundum crucible, and heat them to 1000-1100°C under a reducing atmosphere of activated carbon (or hydrogen, ammonia, etc...

example 1

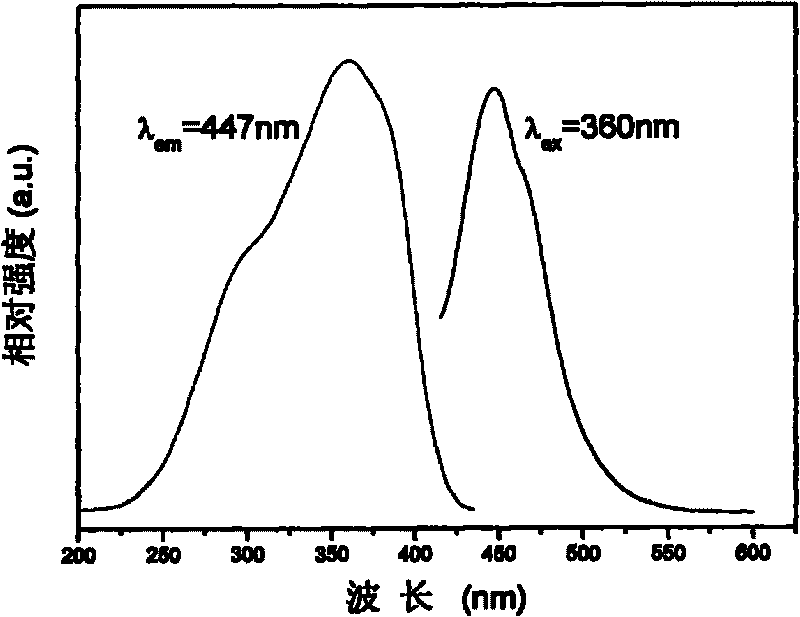

[0019] Blue phosphor for LED, chemical formula is Sr 1.99 Mg 3 P 4 o 15 :1%Eu 2+ , the preparation method is as follows: Weigh the SrCO 3 0.8814g, (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O 0.8744g, NH 4 h 2 PO 4 1.3804g, Eu 2 o 3 0.0053g, add an appropriate amount of ethanol to fully mix various raw materials, dry them and then grind them fully, then move them to a corundum crucible, use a high-temperature muffle furnace to heat to 1070°C under the reducing condition of activated carbon, and keep it warm for 2 hours. After cooling down to room temperature, the samples were taken out and ground into powder to obtain blue-violet phosphors for LEDs. figure 2 The excitation and emission spectra of this phosphor are given.

example 2

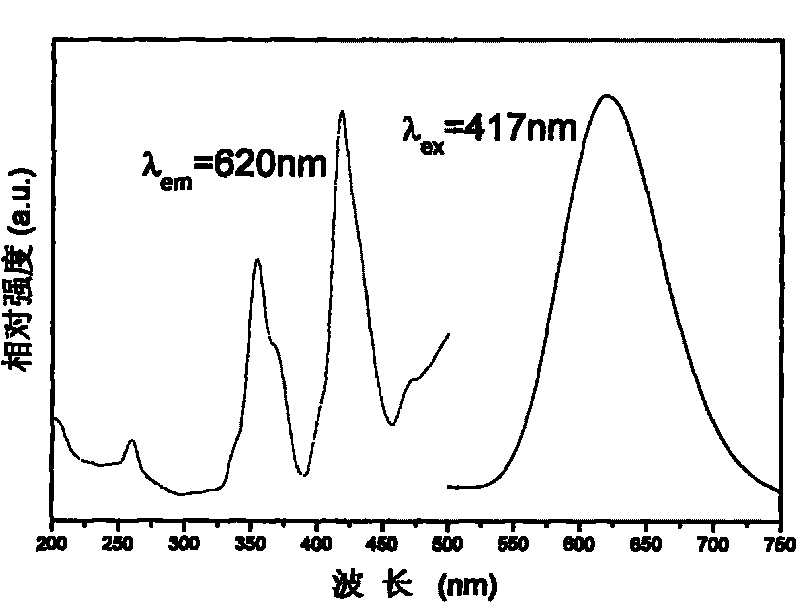

[0021] Red phosphor powder for LED, the chemical formula is Sr 2 Mg 2.80 P 4 o 15 :20%Mn 2+ , the preparation method is as follows:

[0022] Weigh Sr(NO 3 ) 2 1.2698g, MgCO 3 0.7082g, NH 4 h 2 PO 4 1.3804g, MnCO 3 0.0690g, add an appropriate amount of ethanol to mix various raw materials thoroughly, dry them and then grind them fully, then move them to a corundum crucible, use a high-temperature muffle furnace to heat to 1050°C under the reducing condition of ammonia gas, and keep it warm for 4 hours , and then lowered to room temperature, the sample was taken out and ground into powder to obtain the red fluorescent powder for LED. image 3 The excitation and emission spectra of this phosphor are given.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap