Method for preparing porous carbon electrode material

A porous carbon electrode and porous carbon technology are applied in the direction of electrode manufacturing, hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing, etc. It can solve the problems of complex process, difficult to meet, and low capacitance, and achieve good cycle stability. Inexpensive source, the effect of large electrode capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

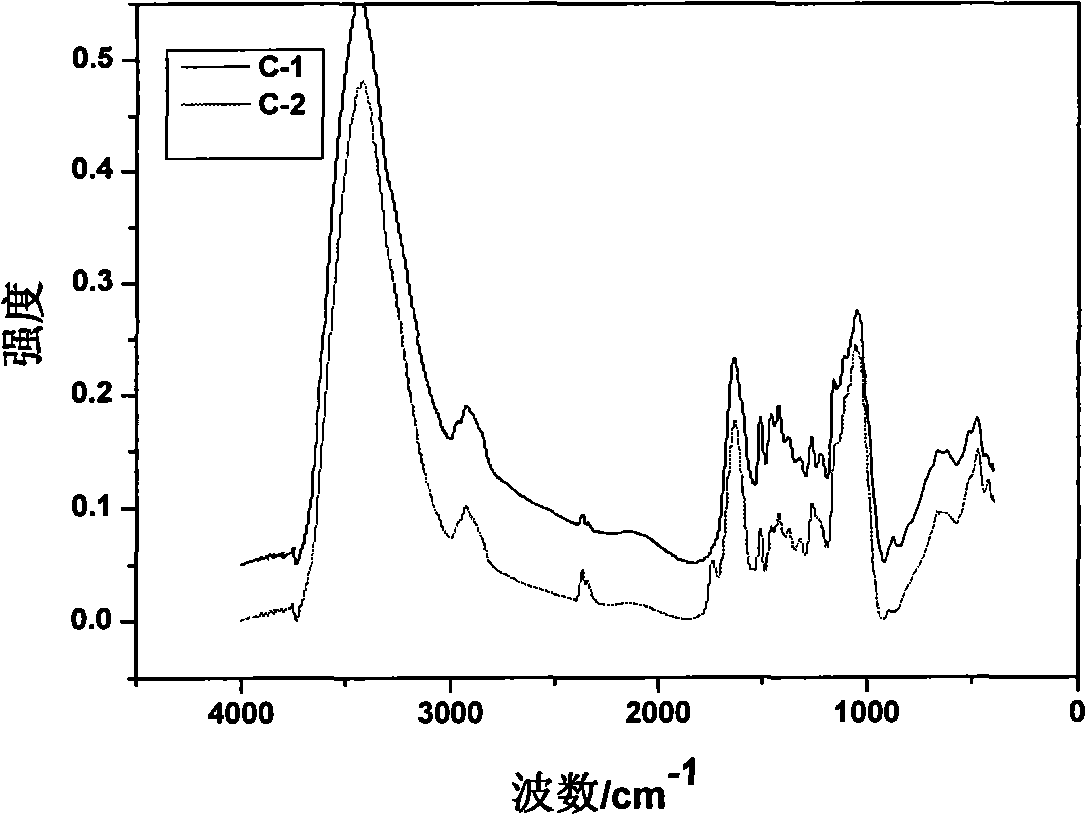

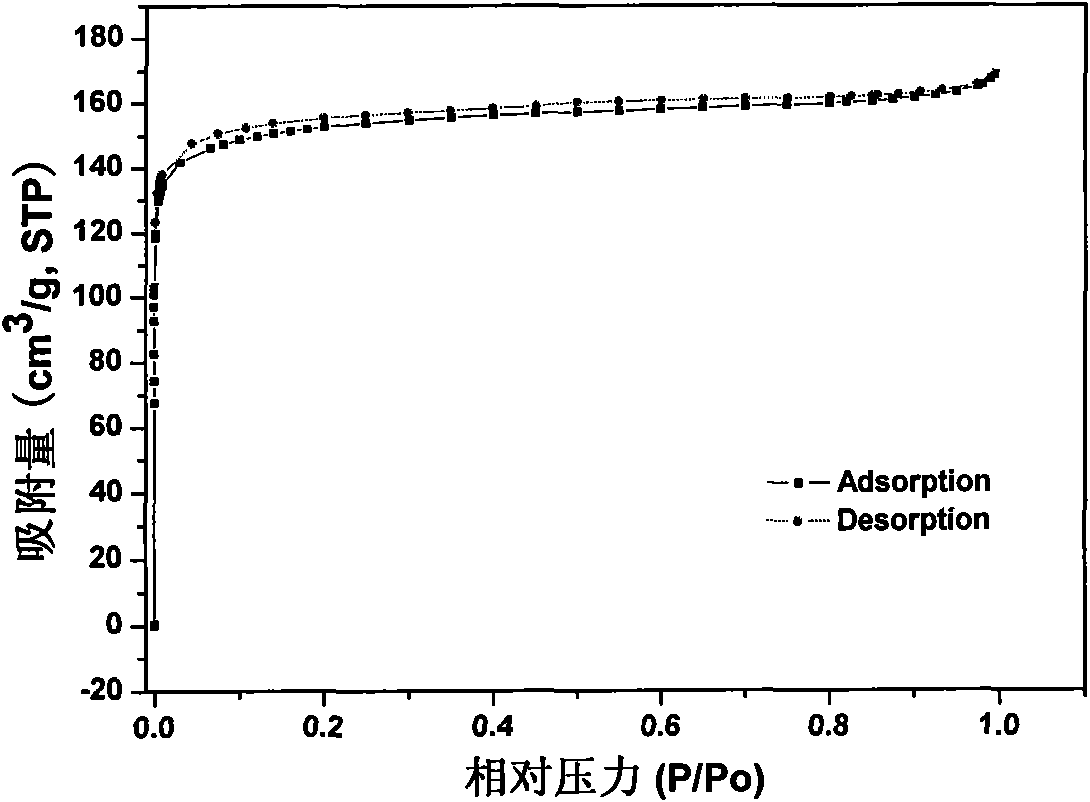

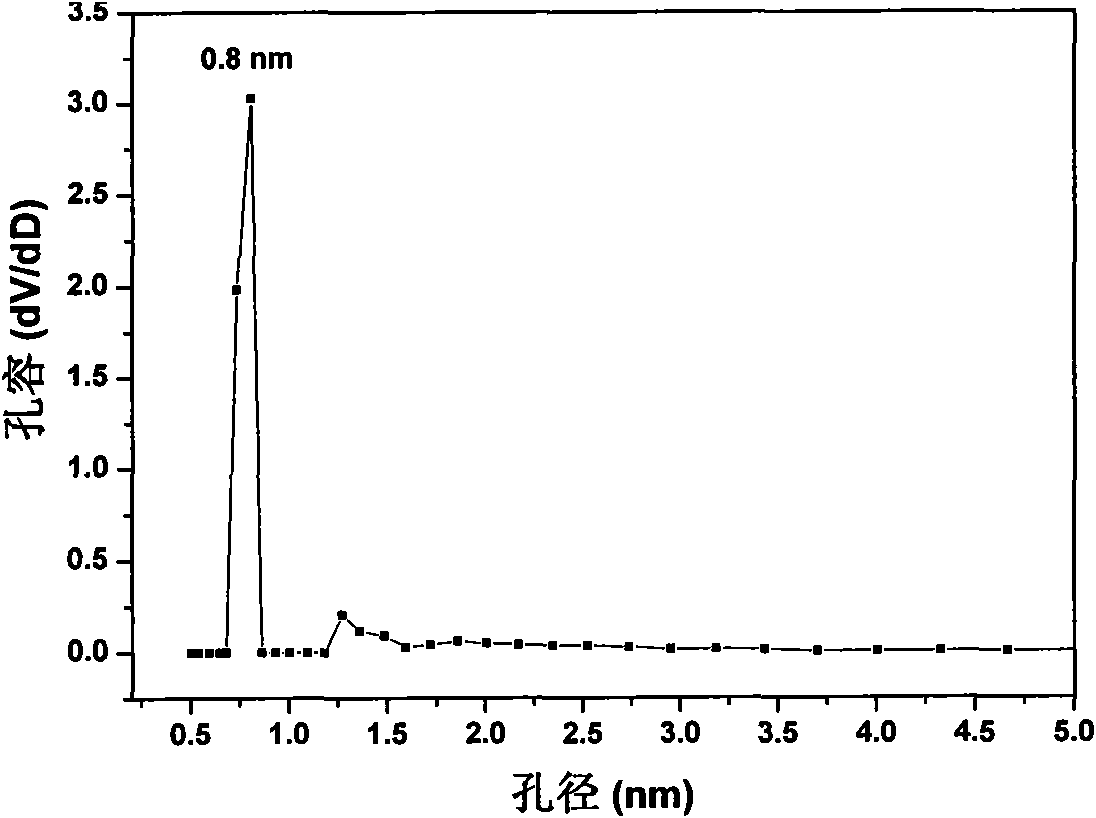

[0026] 1. Preparation of porous carbon: In this example, ordinary dried peanut shells are selected as the basic raw material, and the peanut shells are washed and dried for later use; some dried peanut shells are cut into small pieces, and put into 1mol / L alkaline solution at 80°C Soak under water for 12 hours for pretreatment, then wash and dry; put the peanut shells treated with lye solution and the peanut shells without lye solution into a tubular resistance furnace for carbonization at 800°C for 90 minutes (nitrogen atmosphere), and the obtained samples were treated with 20% concentration Porous carbon was prepared after soaking in HF acid for 72 hours; the obtained samples were taken for testing, and the porous carbon prepared by pretreatment of peanut shells was recorded as C-1, and the porous carbon prepared by non-pretreated peanut shells was recorded as C-2; figure 1 Infrared images of C-1 and C-2, given by figure 1 It can be seen that after the lye pretreatment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com