Method for processing and applying organic fertilizer and processing system

An application method and organic fertilizer technology, applied in the field of agricultural production, can solve the problems of solid organic fertilizers that cannot be drip-applied or fertilized by pipe irrigation, labor-intensive, and inconvenient to operate, so as to solve the problem of resource reuse and reduce environmental pollution. Pollution, the effect of solving reasonable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 farm chicken manure is drip-applied to field crops

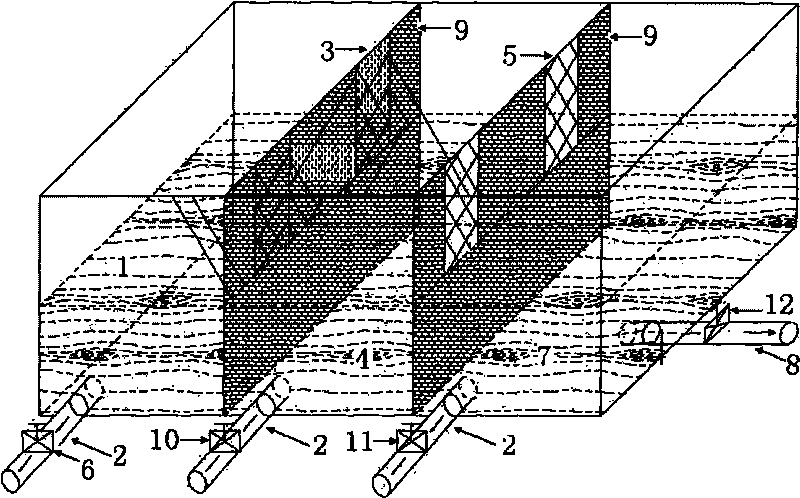

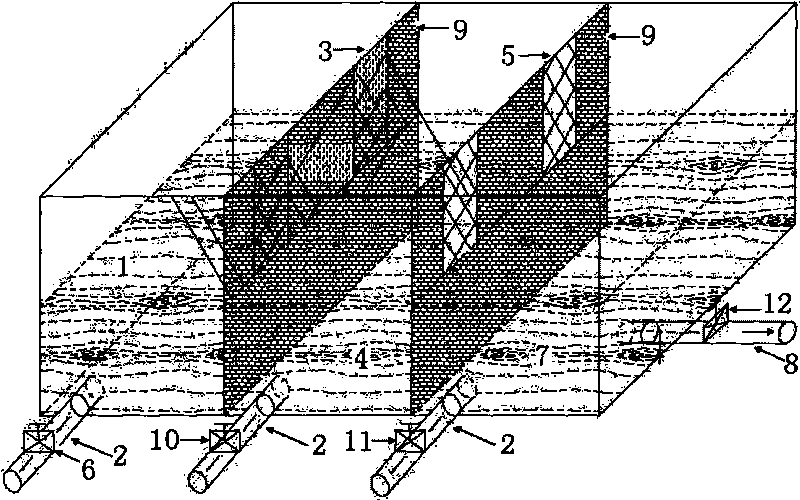

[0025] Adopt the retting processing device shown in accompanying drawing 1. In the attached drawing 1, 1 is a composting tank, 2 is a drain pipe, 3 is a 20-mesh stainless steel filter, 4 is a primary filter, 5 is an 80-mesh stainless steel filter, 6 is a system valve a, and 7 is a secondary filter Pool, 8 is the filtrate outflow pipe, 9 is the spacer layer, 10 is the system valve b, 11 is the system valve c, 12 is the system valve d.

[0026] The retting treatment device comprises a retting tank 1, a filter tank 4 and 7, a filter screen 3 and 5, system valves 6, 10, 11 and 12; Spacer layer 9, filter screen 3 and 5 are arranged on spacer layer 9; Retting pool 1 and filter pool 4 and 7 are all provided with drainpipe, filter pool 7 and drip irrigation device (existing conventional device, not indicated in accompanying drawing 1 ) are connected through the filtrate outflow pipe 8; the drain pipe and the fi...

Embodiment 2

[0036] Embodiment 2 Farmhouse pig manure is drip-applied to field crops

[0037] Adopt the retting treatment device shown in accompanying drawing 1.

[0038] (1) Put the collected pig manure in the composting tank 1, add water to retting for 15-30 days according to the weight ratio of pig manure: water = 1:3; let it fully ferment and decompose.

[0039] The retting solution in the upper layer of the retting tank 1 first enters the primary filter pool 4 through the 20-mesh stainless steel filter screen 3 due to the natural pressure difference, and after reaching a certain liquid level, the filtrate enters the secondary filter pool 7 through the 80-mesh stainless steel filter screen 5;

[0040] (2) Open the system valve d, the filtrate flows out through the filtrate outlet pipe 8, and enters the drip irrigation system after passing through the 120-mesh screen or laminated filter at the head of the drip irrigation device (not marked in Figure 1), and reaches the crop root by the ...

Embodiment 3

[0043] Embodiment 3 Peanut bran or bean cake is applied dropwise to field crops

[0044] Adopt the retting treatment device shown in accompanying drawing 1.

[0045] (1) Put peanut bran or bean cake in the composting pool 1, add water to retting for 30 to 45 days according to the weight ratio of peanut bran: water = 1: 3 ~ 5; bean cake: water = 1: 4; let it fully ferment and decompose .

[0046] The retting solution in the upper layer of the retting tank 1 first enters the primary filter pool 4 through the 20-mesh stainless steel filter screen 3 due to the natural pressure difference, and after reaching a certain liquid level, the filtrate enters the secondary filter pool 7 through the 80-mesh stainless steel filter screen 5;

[0047] (2) Open the system valve d, the filtrate flows out through the filtrate outlet pipe 8, and enters the drip irrigation system after passing through the 120-mesh screen or laminated filter at the head of the drip irrigation device (not marked in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com