Sintering method of yttrium oxide base transparent ceramic

A technology of transparent ceramics and sintering method, which is applied in the field of ceramic material preparation and can solve the problems of difficult operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

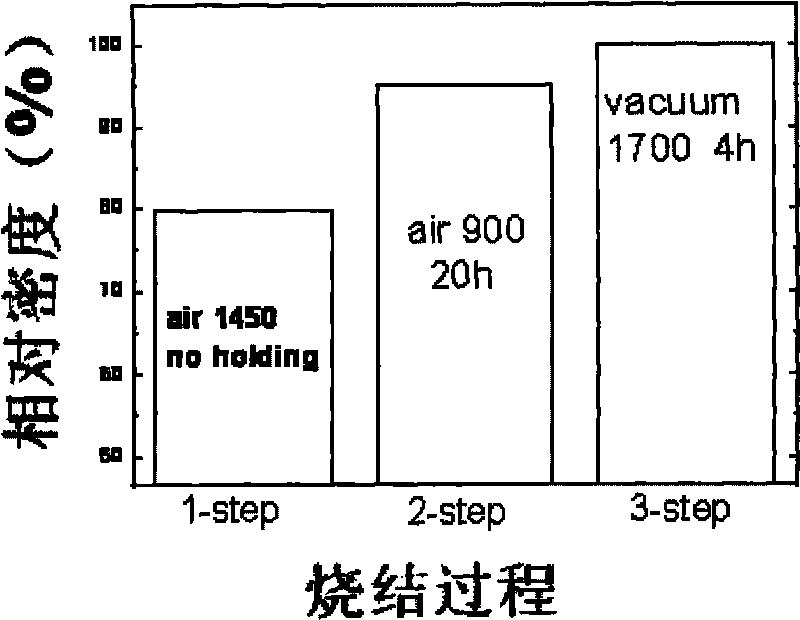

[0038] Embodiment 1: the yttrium oxide powder that is mixed with 7at% lanthanum oxide (the molar number of lanthanum element accounts for the percentage of the sum of lanthanum element and yttrium element molar weight is 7%) (powder particle size is 50~500nm) is mixed with 200MPa The cold isostatic pressed sample was placed in a muffle furnace, and the temperature was raised to 1450°C at a rate of 20°C / min, and then immediately lowered to 900°C at a rate of 50°C / min, and kept at this temperature for 20 hours. Then the sample was taken out at 1800°C for 10 -3 Sintering under Pa vacuum for 8 hours to obtain a 1mm thickness transparent yttrium oxide ceramic sample, see the attached figure 1 , figure 1 A photograph of a transparent ceramic sample standing on paper. image 3 It is a schematic diagram of the sintering process, in which the first step is heating to 1450°C in air, and then immediately cooling down to 900°C; the second step is holding the temperature for 20 hours; th...

Embodiment 2

[0039] Embodiment 2: the yttrium oxide powder that is mixed with 7at% lanthanum oxide (the mole number of lanthanum element accounts for the percentage of the sum of lanthanum element and yttrium element mole number is 7%) (powder particle size is 50~500nm) 200MPa cooling Put it into a muffle furnace after isostatic pressing, raise the temperature to 1350°C at a rate of 5°C / min, immediately cool down to 1000°C at 30°C / min, and keep the temperature for 40 hours. Then put the sample in a vacuum furnace and sinter at 1700°C for 2 hours to obtain a transparent ceramic with a thickness of 2mm, see attached figure 2 , figure 2 It is a photo taken of a transparent ceramic sample 40cm above the white paper and 20cm in front of the camera lens. The chemical formula of the prepared yttrium oxide-based transparent ceramics is Y 1.86 La 0.14 o 3 .

Embodiment 3

[0040] Example 3: Mixed powder composed of yttrium oxide powder and zirconia powder (the percentage of the moles of zirconium element to the sum of the moles of zirconium element and yttrium element is 2at%) (the particle size of the powder is 50-500nm ) was dry pressed and formed by 70MPa cold isostatic pressing; then the formed mixed powder was put into a muffle furnace, and the temperature was raised to 1400°C at a heating rate of 20°C / min; then the temperature was immediately lowered to 900°C and kept for 40 Hour. Then place the heat-preserved mixed powder in a vacuum sintering furnace for sintering at 1700° C. for 10 hours. In the prepared yttrium oxide-based transparent ceramics, its chemical formula is Y 1.96 Zr 0.04 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com