Light and thin composite hot water heating floor

A hot water heating and composite technology, applied in hot water central heating systems, heating methods, household heating and other directions, can solve the problems of low pressure resistance and deformation resistance of thermal insulation materials, inability to meet user requirements, and high water quality requirements. Improve the mechanical and thermal properties such as compression resistance, appropriate thermal conductivity, and simplify construction and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The mechanism, specific structure and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

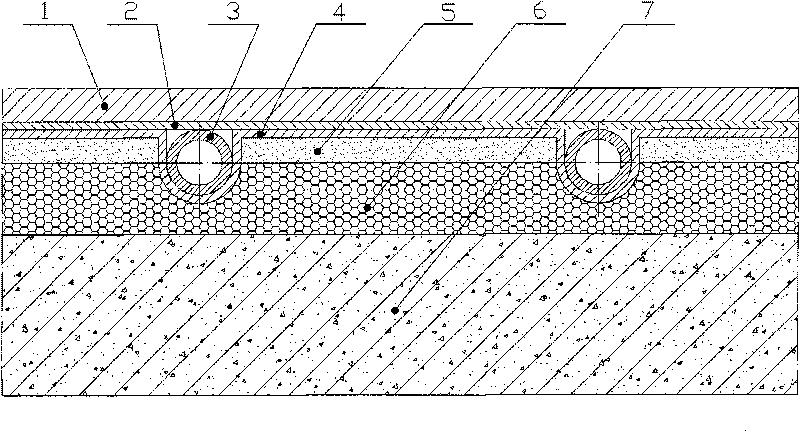

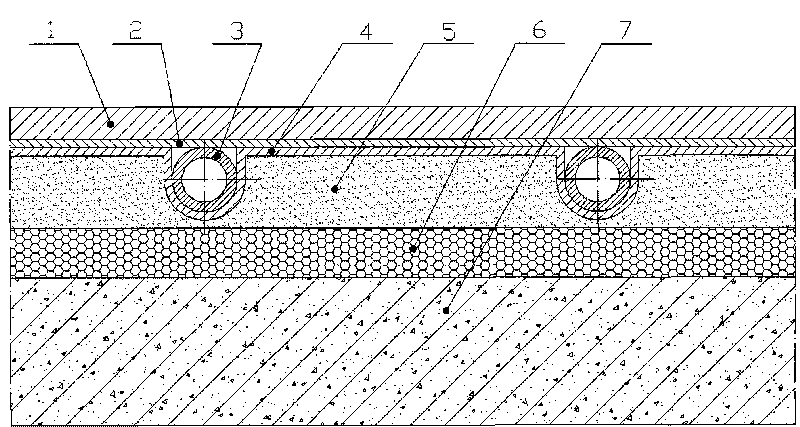

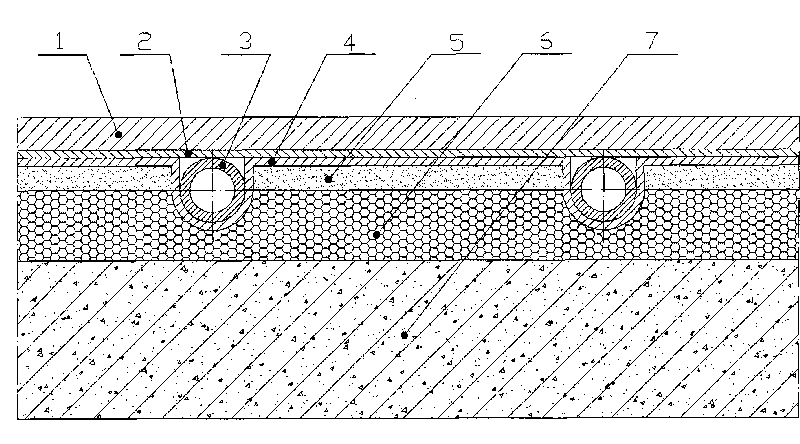

[0019] figure 1 The structural diagram of the first embodiment provided by the present invention, the floor includes a ground decoration layer 1, an upper metal heat conduction layer 2, a heating pipe 3, a lower metal heat conduction layer 4, a silicon-calcium board 5, an insulation layer 6, and a floor slab 7; Pipe grooves are set in the silicon-calcium board and the insulation layer, and the lower metal heat-conducting layer and the surface of the pipe groove are laid next to each other, and prefabricated with the silicon-calcium board and the insulation layer to form a prefabricated composite board with pipe grooves. The heating tube 3 is placed on the lower metal heat-conducting layer in the pipe groove; the upper metal heat-conducting layer is laid horizontally on the heating tube and the lower metal heat-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com