Polymer coagulant

A coagulant and polymer technology, which is applied in the field of water treatment reagents, can solve the problems of not being suitable for long-term storage, can only be used at any time, and high operating costs, achieving remarkable effects, convenient dosage, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In parts by weight, in a reaction kettle at 30°C, dissolve 25 parts of anionic polyacrylamide into 40 parts of water under stirring, and gradually add 15 parts of dispersant sodium bicarbonate, stir evenly, and then, under stirring, Add 5 parts of non-ionic polyacrylamide and 5 parts of cationic polyacrylamide. After completely dissolving, use 10% hydrochloric acid aqueous solution to adjust the pH value to 6.5-7.5, stir evenly, and gradually cool to room temperature to obtain colorless or slightly It turns into a yellow transparent solution, and adding 2-5ppm of the transparent solution to the sewage can significantly improve the sedimentation effect, and the chemical oxygen demand (COD) and chromaticity index of the treated sewage are also significantly improved. The test data are shown in Table 1 below.

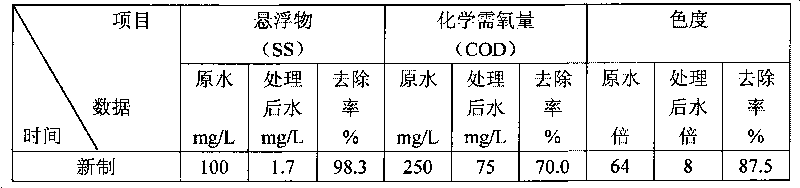

[0024] Table 1: Water treatment effect data of the polymer coagulant obtained in Example 1:

[0025]

[0026]

[0027] The polymer coagulant liquid did not a...

Embodiment 2

[0029] In parts by weight, in a reaction kettle at 50°C, dissolve 5 parts of anionic polyacrylamide into 45 parts of water under stirring, and gradually add 10 parts of dispersant sodium carbonate, stir evenly, and then, under stirring, Add 5 parts of non-ionic polyacrylamide and 25 parts of cationic polyacrylamide. After completely dissolving, use 10% hydrochloric acid aqueous solution to adjust the pH value to 6.5-7.5, stir evenly, and gradually cool to room temperature to obtain colorless or slightly It turns into a yellow transparent solution, and adding 2-5ppm of the transparent solution to the sewage can significantly improve the sedimentation effect, and the chemical oxygen demand (COD) and chromaticity index of the treated sewage are also significantly improved. The test data is shown in Table 2 below.

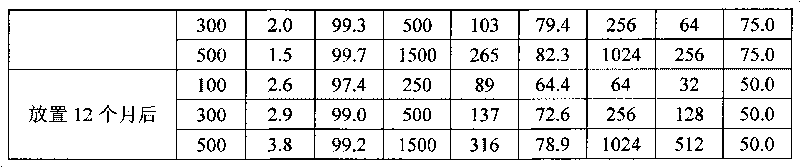

[0030] Table 2: The water treatment effect data of the polymer coagulant obtained in Example 2:

[0031]

[0032] The polymer coagulant liquid did not appear cloud...

Embodiment 3

[0034] In parts by weight, in a reaction kettle at 65°C, dissolve 5 parts of anionic polyacrylamide into 50 parts of water under stirring, and gradually add 8 parts of dispersant sodium sulfate, stir evenly, and then, under stirring, Add 25 parts of nonionic polyacrylamide and 5 parts of cationic polyacrylamide. After completely dissolving, use 10% hydrochloric acid and 5% ammonia solution to adjust the pH value to 6.5-7.5, stir evenly, and gradually cool to room temperature to obtain Colorless or slightly yellow transparent solution, adding 2-5ppm of this transparent solution to the sewage can significantly improve the sedimentation effect, and the COD (Chemical Oxygen Demand) and chromaticity index of the treated sewage are also significantly improved . The test data are shown in Table 3 below.

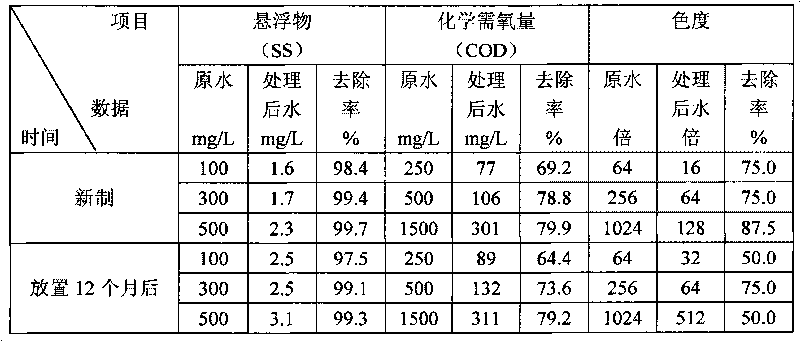

[0035] Table 3: The water treatment effect data of the polymer coagulant obtained in Example 3:

[0036]

[0037] The polymer coagulant liquid did not appear cloudy, coagulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com