Intelligent active freezing-proof coating material and preparation method and application thereof

A coating material and anti-icing technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve the effects of reducing usage, benefiting environmental protection, and flexible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

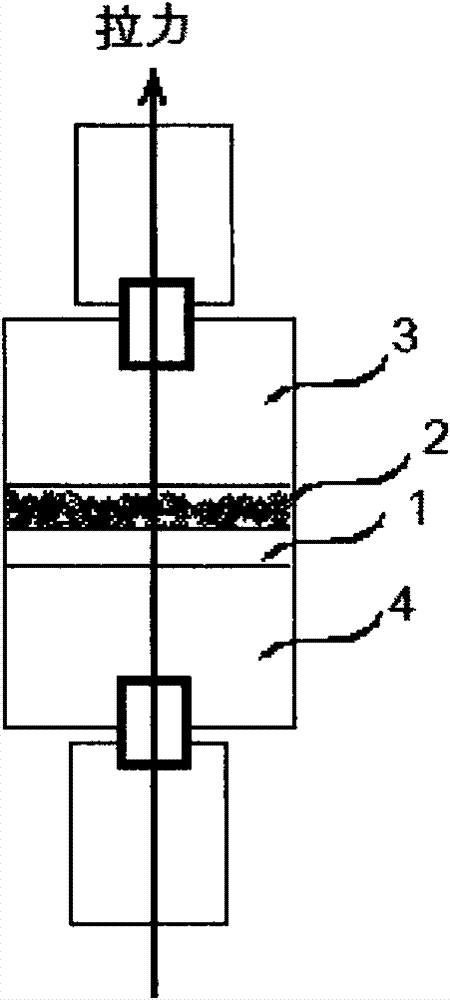

Image

Examples

preparation example Construction

[0023] 1. Preparation of temperature-sensitive phase change materials

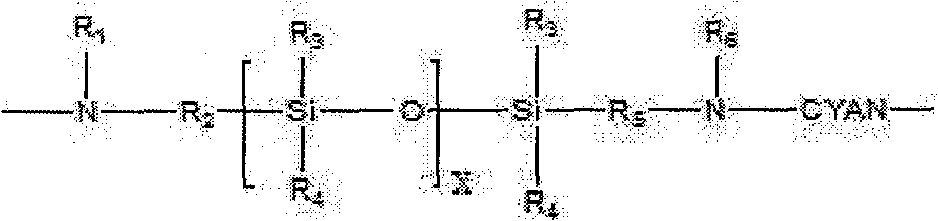

[0024] The temperature-sensitive phase change material is prepared by reacting α, ω-bishydroxy polysiloxane and alkoxy silicon, and the molecular formula is as follows:

[0025] where R 1 , R 2 , R 5 , R 6 is an alkoxy or aryloxy group containing 1-10 C atoms; R 3 , R 4 It is an alkyl, phenyl or cycloalkyl group containing 1-6 C atoms; the number of repeating units X and Y is 3-30; the number of repeating units Z of polysiloxane is 3-10.

[0026] 2. Preparation of high molecular weight polymers containing ureide groups

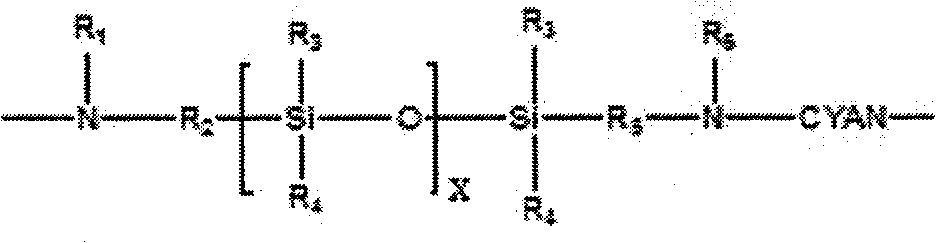

[0027] The synthesis of polymers containing ureide groups adopts the reaction of high molecular weight α, ω-bisaminopolysiloxane and diisocyanate to prepare high molecular weight polymers containing ureide groups. The molecular structure is as follows:

[0028]

[0029] where R 1 , R 6 It is a hydrogen group, an alkyl group with 1-6 carbon atoms, an aryl group, a cycloalkyl g...

Embodiment 1

[0034] (1) Preparation of temperature-sensitive phase change materials

[0035] Nitrogen was blown, the residual air in the 10L glass polymerization reactor was taken out, and 5mol α, ω-bishydroxy polydimethylsiloxane (M W1200) and 2.5 L of dichloromethane. Weigh 10 mol of hexadecyltrimethoxysilane and dissolve it in 2.5 L of dichloromethane and 12 mol of oxalic acid. Start the stirring device, and slowly add the alkyltrimethoxysilane mixture dropwise. After the dropwise addition, the temperature was raised to 50° C. to continue the reaction for 2 hours, and the excess solvent and small molecular impurities were removed by gradually raising the temperature. The obtained temperature-sensitive phase change material was washed several times with deionized water, dried in vacuum until constant weight, and set aside.

[0036] (2) Preparation of high molecular weight polymers containing ureide groups

[0037] Nitrogen was blown to take out the residual air in the 10L glass polym...

Embodiment 2

[0039] Nitrogen was blown, the residual air in the 10L glass polymerization reactor was taken out, and 5mol α, ω-bishydroxy polydimethylsiloxane (M W 1200) and 2.5 L of dichloromethane. Weigh 10 mol of octadecyltrimethoxysilane and dissolve it with 2.5 L of dichloromethane and 12 mol of oxalic acid. Start the stirring device, and slowly add the alkyltrimethoxysilane mixture dropwise. After the dropwise addition, the temperature was raised to 50° C. to continue the reaction for 2 hours, and the excess solvent and small molecular impurities were removed by gradually raising the temperature. The obtained temperature-sensitive phase change material was washed several times with deionized water, dried in vacuum until constant weight, and set aside.

[0040] Nitrogen was blown to take out the residual air in the 10L glass polymerization reactor, and poured into 2.5L of dichloromethane and 5mol fumaryl chloride mixed solution. Weigh 10mol α, ω-bisaminopolysiloxane (M W 25000) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com