Self-cleaning automobile coating and preparation method thereof

A self-cleaning, automotive technology, applied in coatings and other directions, can solve the problems of not applying self-cleaning coatings for auto parts, and achieve the effects of improving photocatalytic performance, excellent anti-fog, and good self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

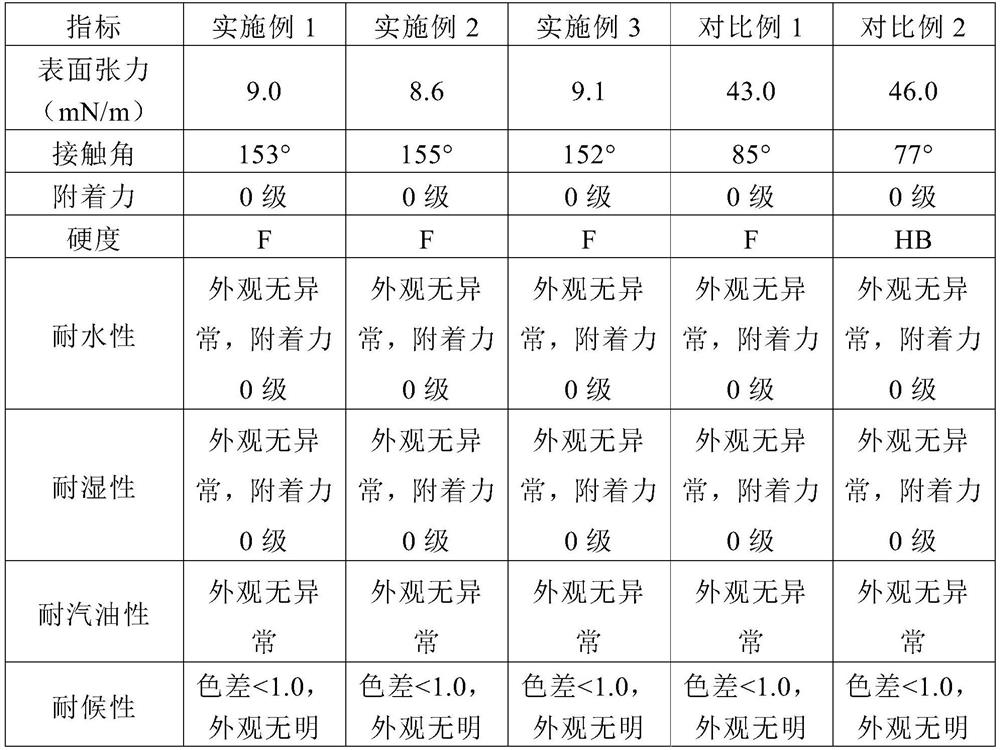

Examples

Embodiment 1

[0049] A kind of self-cleaning automobile paint, the raw material includes the following components by mass percentage: self-made nano-titanium dioxide 36%, thermoplastic acrylic resin 12%, BYK161 dispersant 1.5%, BYK306 organosilicon leveling agent 0.5%, DEGUSSA-A200 anti-settling agent 4%, TINUVIN 384-2 UV absorber 2%, butyl acetate 22%, ethyl acetate 16%, propylene glycol methyl ether acetate 6%. Among them, the thermoplastic acrylic resin is a thermoplastic acrylic resin with a solid content of 40% and a molecular weight of 80,000, and its Tg is 92°C.

[0050] (1) Mix silicone leveling agent with butyl acetate and propylene glycol methyl ether acetate, stir at 300r / min for 10min, then add self-made nano-titanium dioxide, continue stirring at 300r / min for 30min; after stirring evenly, Soak for 3 hours, so that the organic silicon leveling agent is fully adsorbed on the surface of nano-titanium dioxide, and a slurry is prepared.

[0051] (2) Add the dispersant to the thermo...

Embodiment 2

[0055] A kind of self-cleaning automobile paint, the raw material includes the following components by mass percentage: self-made nano-titanium dioxide 38%, thermoplastic acrylic resin 13.5%, BYK163 dispersant 2.0%, BYK331 organosilicon leveling agent 0.5%, DEGUSSA-A200 anti-settling agent 4%, TINUVIN 123 UV absorber 2%, butyl acetate 20%, ethyl acetate 15%, propylene glycol methyl ether acetate 5%. Wherein, the thermoplastic acrylic resin is a thermoplastic acrylic resin with a solid content of 45% and a molecular weight of 90,000, and its Tg is 94°C.

[0056] (1) Mix silicone leveling agent with butyl acetate and propylene glycol methyl ether acetate, stir at 500r / min for 5min, then add self-made nano-titanium dioxide, continue stirring at 500r / min for 20min; after stirring evenly, Soak for 3.6 hours, so that the organic silicon leveling agent is fully adsorbed on the surface of nano-titanium dioxide, and a slurry is prepared.

[0057] (2) Add the dispersant to the thermopl...

Embodiment 3

[0061] A kind of self-cleaning automobile coating, raw material comprises the following components by mass percentage: self-made nano-titanium dioxide 35%, thermoplastic acrylic resin 11%, EFKA-4010 dispersant 1.5%, Tego Glid 100 organosilicon leveling agent 0.8%, DEGUSSA- A200 anti-settling agent 3.5%, TINUVIN 384-2 ultraviolet absorber 2.2%, butyl acetate 24%, ethyl acetate 16%, propylene glycol methyl ether acetate 6%. Wherein, the thermoplastic acrylic resin is a thermoplastic acrylic resin with a solid content of 50%, a molecular weight of 100,000, and a Tg of 95°C.

[0062] (1) Mix silicone leveling agent with butyl acetate and propylene glycol methyl ether acetate, stir at 400r / min for 8min, then add self-made nano-titanium dioxide, continue stirring at 400r / min for 25min; after stirring evenly, Soak for 4 hours, so that the organic silicon leveling agent is fully adsorbed on the surface of nano-titanium dioxide, and a slurry is prepared.

[0063] (2) Add the dispersan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com