Method for constructing energy-saving underground tube structure

A resource-saving and construction method technology, applied to underwater structures, underground chambers, buildings, etc., can solve the problems of high difficulty in anti-seepage treatment, high construction cost, and long construction period, so as to save auxiliary operation time and reduce The effect of low cost of measures and hoisting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

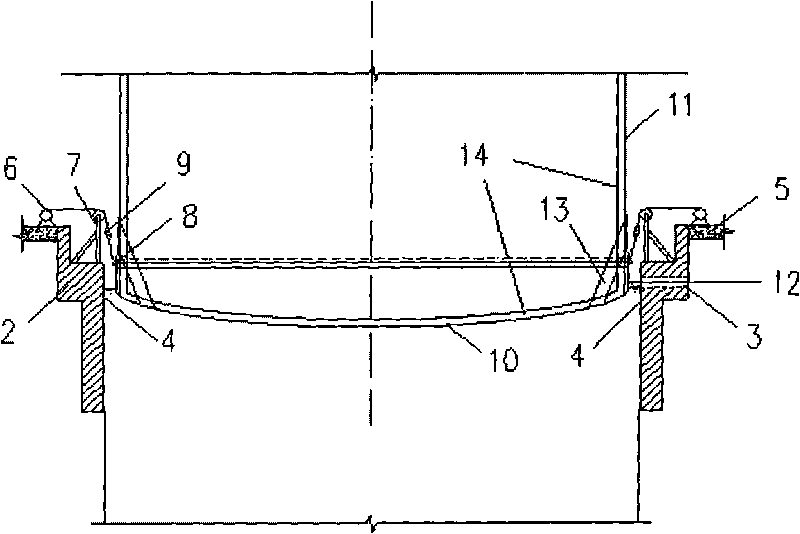

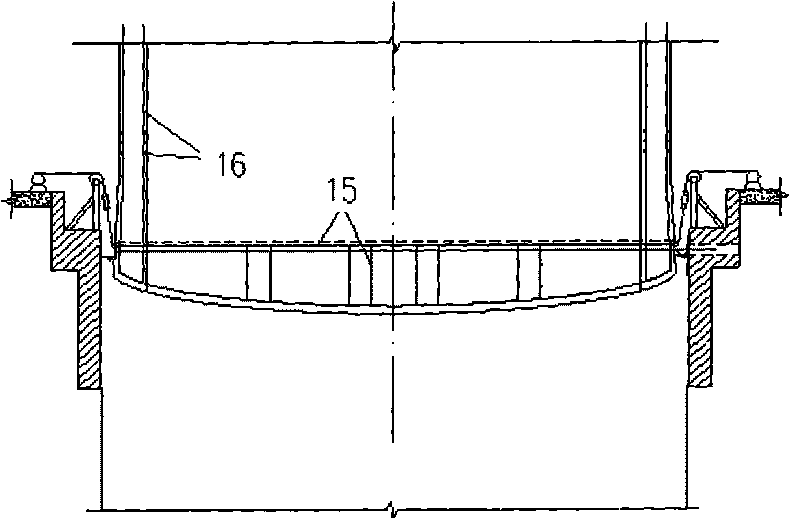

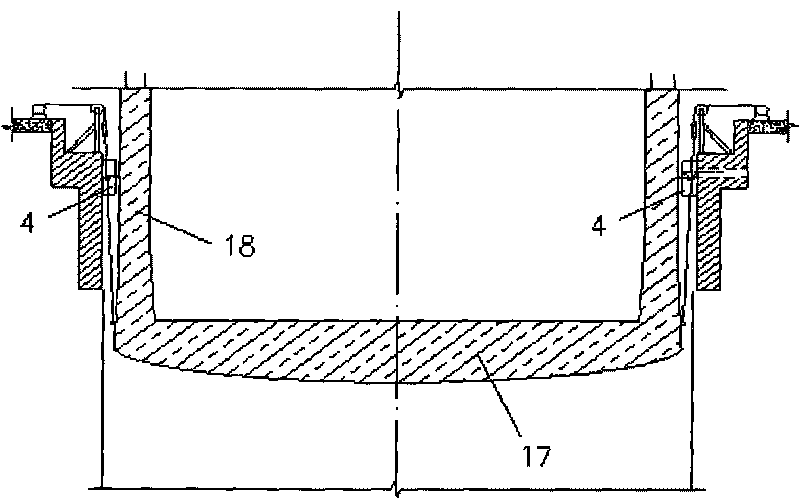

[0053] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar technology, similar structure and similar changes of the present invention should be included in the protection of the present invention scope.

[0054] like Figure 1-Figure 6 As shown, the construction method of a resource-saving underground cylindrical structure provided by the embodiment of the present invention is characterized in that the specific steps are as follows:

[0055] 1) Determine the design position of the underground cylinder structure and the hole, and carry out the preliminary foundation construction according to the designed hole position and design aperture. Set the mud discharge hole groove 3, and set a uniform number of concrete foundations for the hoisting device around the lock 2;

[0056] Wherein, the inner wall of the lock po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com