Method and device for producing high temperature air for quick cooling of large turbine

A high-temperature air and rapid cooling technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of rapid cooling of large steam turbines, small cooling air flow, and difficult control, etc., to achieve small thermal stress, The cooling speed is fast and the effect of continuous adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

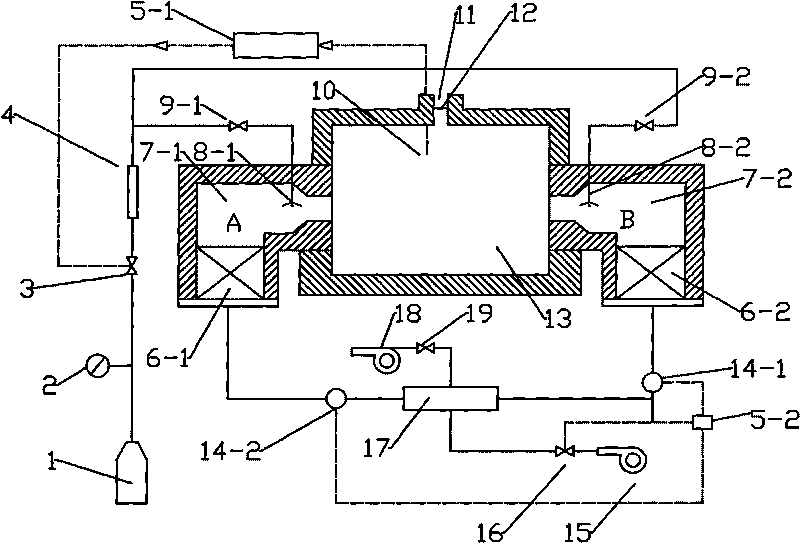

[0030] Such as figure 1 As shown, the high-temperature air production device used for rapid cooling of large steam turbines is mainly divided into four parts: the first part is the gas delivery device, including gas bottle 1, pressure gauge 2, gas control valve 3, flow meter 4, solenoid valve One 9-1, two solenoid valves 9-2, one burner 8-1 and two burner 8-2. The gas bottle 1 is connected with the gas regulating valve 3 and one of the flowmeters 4 sequentially through the pipeline, and the one of the flowmeters 4 is connected with the burner one 8-1 and the burner respectively through the solenoid valve one 9-1 and the solenoid valve two 9-1. Mouth two 8-2 connections. The pressure gauge 2 is arranged on the pipeline connecting the gas bottle 1 and the gas regulating valve 3 for measuring gas pressure. The first burner 8-1 and the second burner 8-2 have a pulse ignition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com